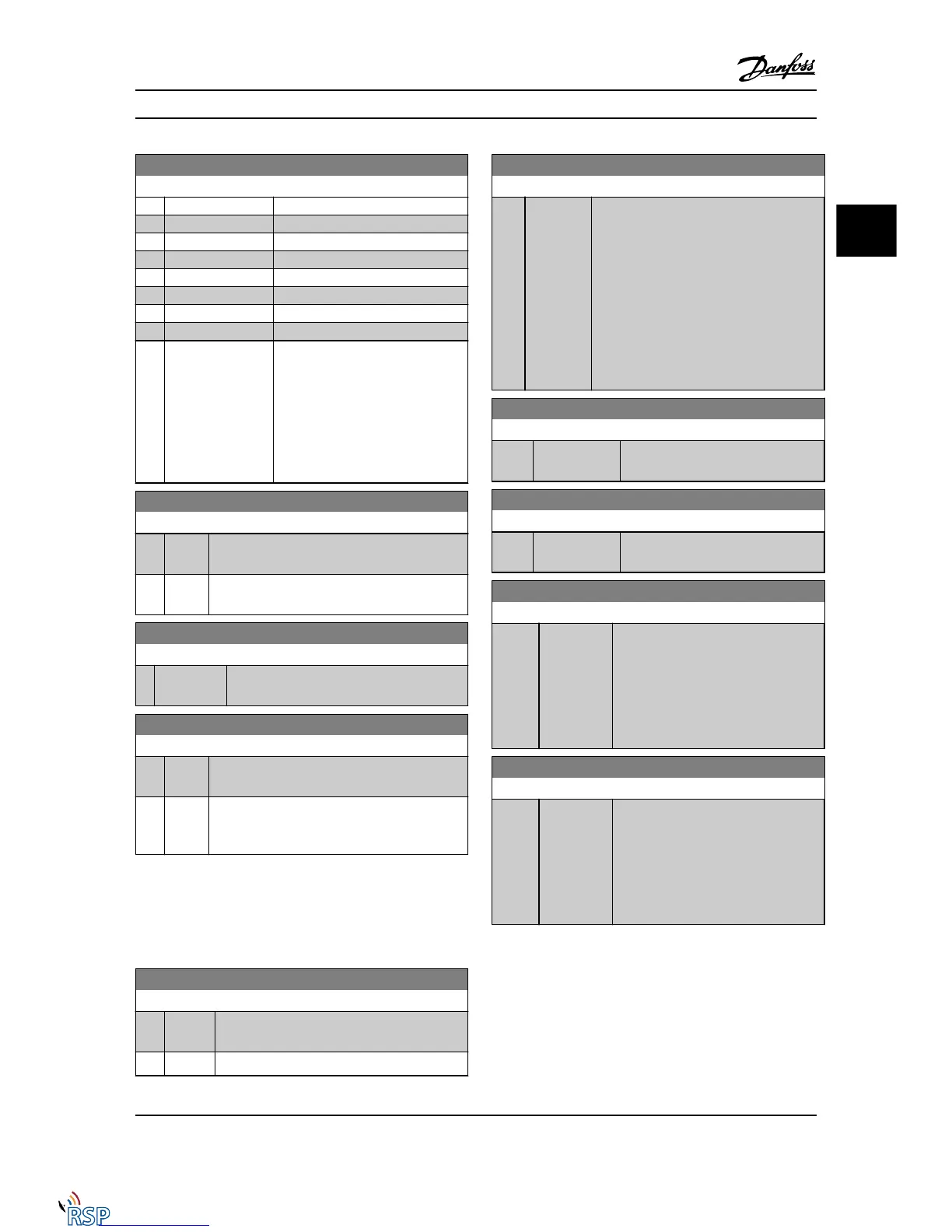

7-45 Process PID Feed Fwd Resource

Option: Function:

[1] Analog input 53

[2] Analog input 54

[7] Frequency input 29

[8] Frequency input 33

[11] Local bus reference

[20] Digital pot.meter

[21] Analog input X30-11

[22] Analog input X30-12

[32] Bus PCD

Selects a bus reference configured by

8-02 Control Word Source. Change

8-42 PCD write configuration for the

bus used in order to make the feed-

forward available in 7-48 PCD Feed

Forward. Use index 1 for feed-forward

[748] (and index 2 for reference

[1682]).

7-46 Process PID Feed Fwd Normal/ Inv. Ctrl.

Option: Function:

[0] * Normal Select Normal [0] to set the feed forward factor to

treat the FF resource as a positive value.

[1] Inverse Select Inverse [1] to treat the FF resource as a

negative value.

7-48 PCD Feed Forward

Range: Function:

0* [0 - 65535 ]

Read-out parameter where the bus 7-45 Process

PID Feed Fwd Resource [32] can be read.

7-49 Process PID Output Normal/ Inv. Ctrl.

Option: Function:

[0] * Normal Select Normal [0] to use the resulting output from

the process PID controller as is.

[1] Inverse Select Inverse [1] to invert the resulting output

from the process PID controller. This operation is

performed after the feed forward factor is applied.

3.9.6 7-5* Process PID Ctrl.

Parameter group 7-5* is only used if 1-00 Configuration

Mode is set to [7] Extended PID speed CL or [8] Extended

PID Speed OL.

7-50 Process PID Extended PID

Option: Function:

[0] Disabled Disables the extended parts of the process PID

controller.

[1] * Enabled Enables the extended parts of the PID controller.

7-51 Process PID Feed Fwd Gain

Range: Function:

1.00* [0.00 -

100.00 ]

The feed forward is used to obtain the

desired level, based on a well-known signal

available. The PID controller then only takes

care of the smaller part of the control,

necessary because of unknown characters.

The standard feed fwd factor in 7-38 Process

PID Feed Forward Factor is always related to

the reference whereas 7-51 Process PID Feed

Fwd Gain has more choices. In winder

applications, the feed fwd factor will typically

be the line speed of the system.

7-52 Process PID Feed Fwd Ramp up

Range: Function:

0.01 s* [0.01 - 10.00 s] Controls the dynamics of the feed

forward signal when ramping up.

7-53 Process PID Feed Fwd Ramp down

Range: Function:

0.01 s* [0.01 - 10.00 s] Controls the dynamics of the feed

forward signal when ramping down.

7-56 Process PID Ref. Filter Time

Range: Function:

0.001 s* [0.001 -

1.000 s]

Set a time constant for the reference first

order low-pass filter. The low-pass filter

improves steady-state performance and

dampens oscillations on the reference/

feedback signals. However, severe

filtering can be detrimental to dynamic

performance.

7-57 Process PID Fb. Filter Time

Range: Function:

0.001 s* [0.001 -

1.000 s]

Set a time constant for the feedback first

order low-pass filter. The low-pass filter

improves steady-state performance and

dampens oscillations on the reference/

feedback signals. However, severe

filtering can be detrimental to dynamic

performance.

Parameter Descriptions FC 300 Programming Guide

MG33MD22 - VLT

®

is a registered Danfoss trademark 3-83

3

3

Loading...

Loading...