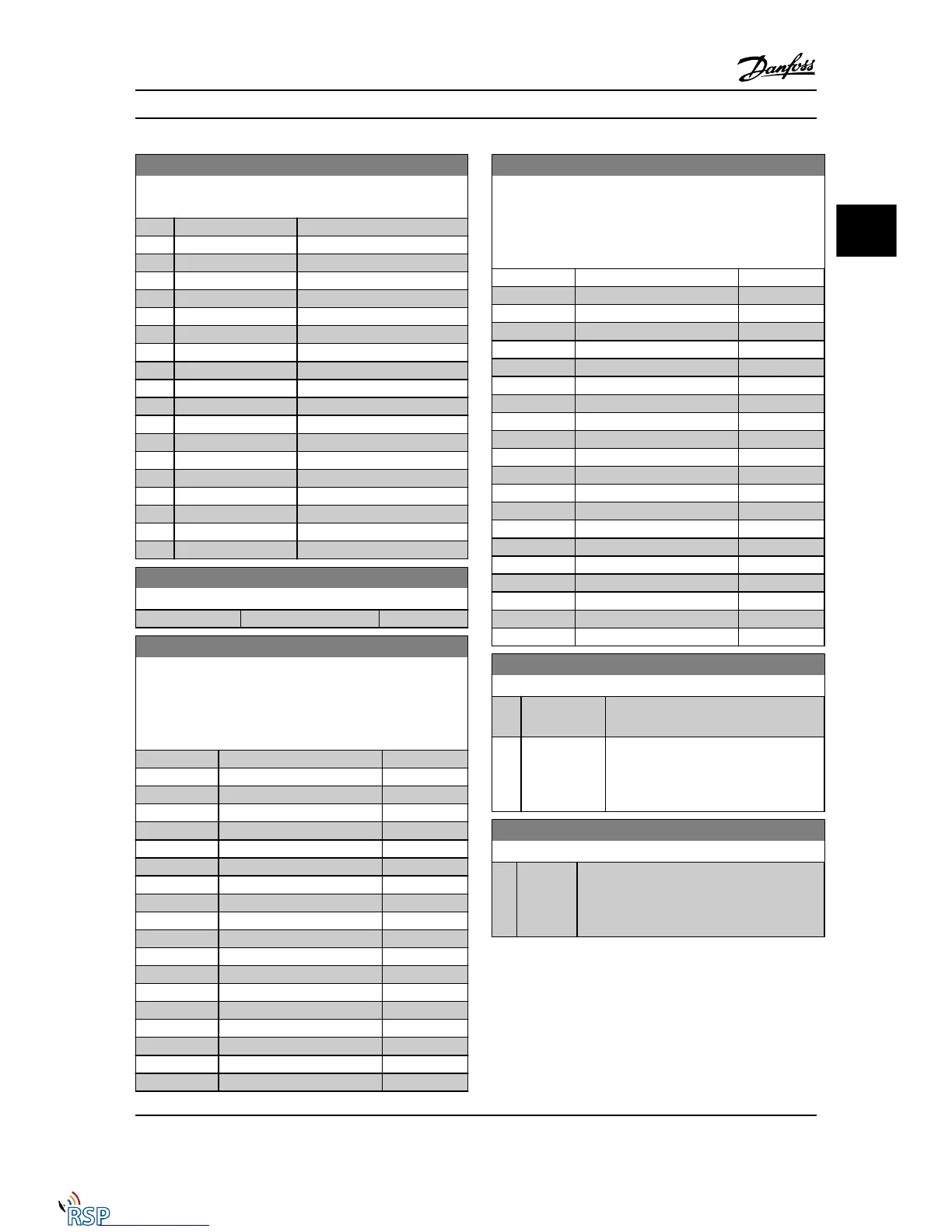

15-10 Logging Source

Array [4]

Option: Function:

[1650] External Reference

[1651] Pulse Reference

[1652] Feedback [Unit]

[1657] Feedback [RPM]

[1660] Digital Input

[1662] Analog Input 53

[1664] Analog Input 54

[1665] Analog Output 42 [mA]

[1666] Digital Output [bin]

[1675] Analog In X30/11

[1676] Analog In X30/12

[1677] Analog Out X30/8 [mA]

[1690] Alarm Word

[1692] Warning Word

[1694] Ext. Status Word

[1860] Digital Input 2

[3110] Bypass Status Word

[3470] MCO Alarm Word 1

[3471] MCO Alarm Word 2

15-11 Logging Interval

Range: Function:

Size related* [ 0.000 - 0.000 ]

15-12 Trigger Event

Select the trigger event. When the trigger event occurs, a

window is applied to freeze the log. The log will then retain a

specified percentage of samples before the occurrence of the

trigger event (15-14 Samples Before Trigger).

Option: Function:

[0] * False

[1] True

[2] Running

[3] In range

[4] On reference

[5] Torque limit

[6] Current limit

[7] Out of current range

[8] Below I low

[9] Above I high

[10] Out of speed range

[11] Below speed low

[12] Above speed high

[13] Out of feedb. range

[14] Below feedb. low

[15] Above feedb. high

[16] Thermal warning

[17] Mains out of range

[18] Reversing

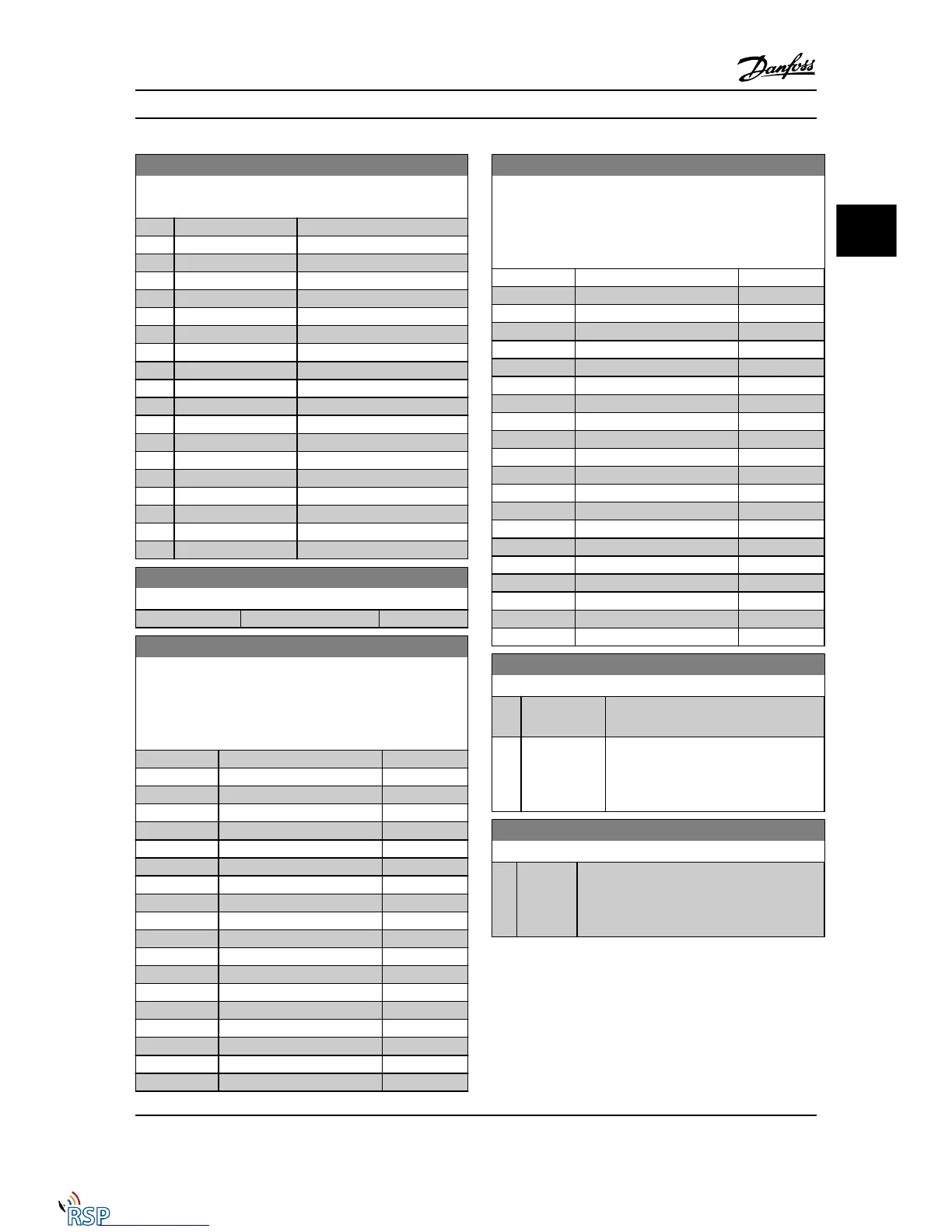

15-12 Trigger Event

Select the trigger event. When the trigger event occurs, a

window is applied to freeze the log. The log will then retain a

specified percentage of samples before the occurrence of the

trigger event (15-14 Samples Before Trigger).

Option: Function:

[19] Warning

[20] Alarm (trip)

[21] Alarm (trip lock)

[22] Comparator 0

[23] Comparator 1

[24] Comparator 2

[25] Comparator 3

[26] Logic rule 0

[27] Logic rule 1

[28] Logic rule 2

[29] Logic rule 3

[33] Digital input DI18

[34] Digital input DI19

[35] Digital input DI27

[36] Digital input DI29

[37] Digital input DI32

[38] Digital input DI33

[50] Comparator 4

[51] Comparator 5

[60] Logic rule 4

[61] Logic rule 5

15-13 Logging Mode

Option: Function:

[0] * Log always

Select Log always [0] for continuous

logging.

[1] Log once on

trigger

Select Log once on trigger [1] to

conditionally start and stop logging using

15-12 Trigger Event and 15-14 Samples

Before Trigger.

15-14 Samples Before Trigger

Range: Function:

50* [0 - 100 ] Enter the percentage of all samples prior to a

trigger event which are to be retained in the

log. See also 15-12 Trigger Event and

15-13 Logging Mode.

3.16.3 15-2* Historic Log

View up to 50 logged data items via the array parameters

in this parameter group. For all parameters in the group,

[0] is the most recent data and [49] the oldest data. Data is

logged every time an event occurs (not to be confused

Parameter Descriptions FC 300 Programming Guide

MG33MD22 - VLT

®

is a registered Danfoss trademark 3-137

3

3

Loading...

Loading...