3.14 Parameters: 13-** Smart Logic Control

3.14.1 Prog. Features

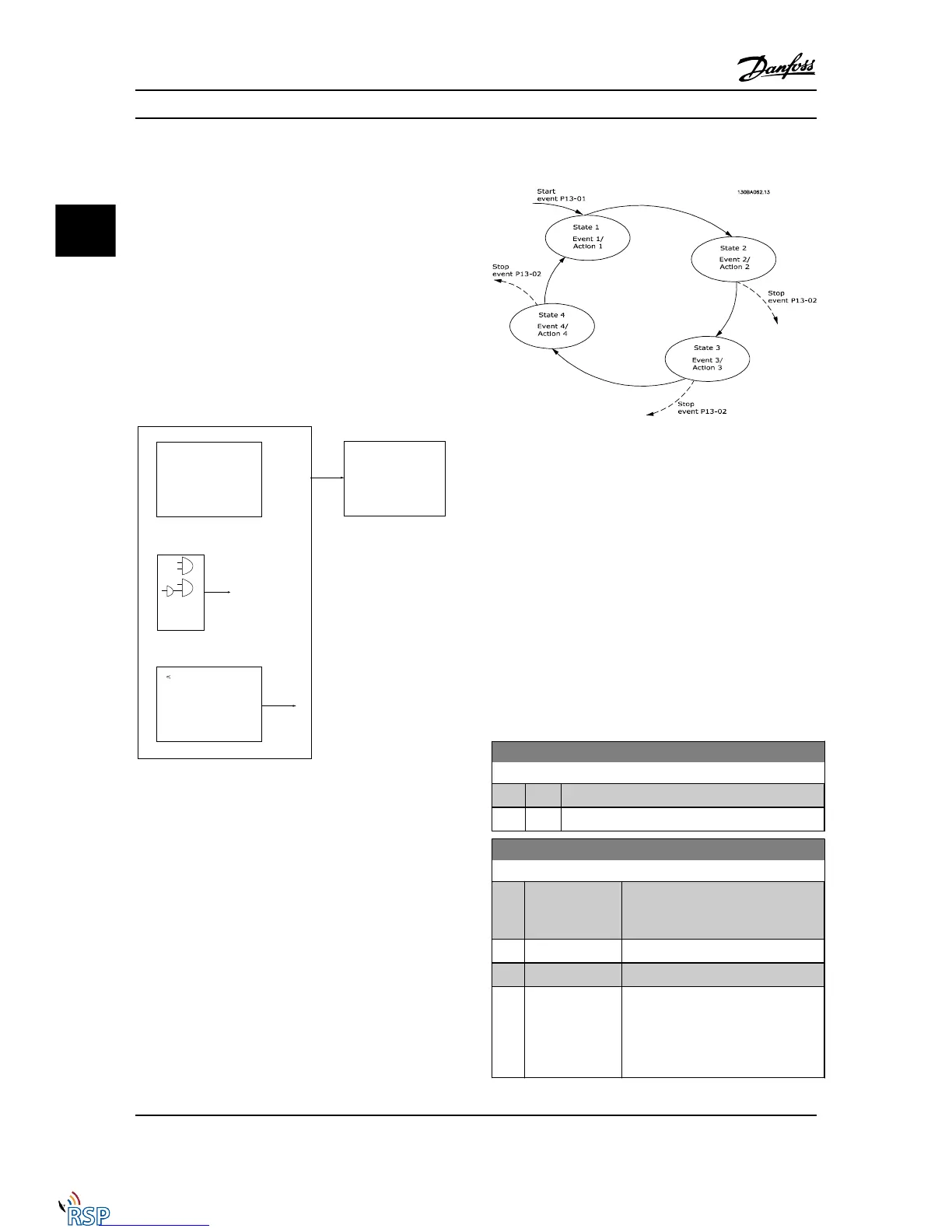

Smart Logic Control (SLC) is essentially a sequence of user-

defined actions (see 13-52 SL Controller Action [x]) executed

by the SLC when the associated user-defined event (see

13-51 SL Controller Event [x]) is evaluated as TRUE by the

SLC .

The condition for an event can be a particular status or

that the output from a logic rule or a comparator operand

becomes TRUE. That will lead to an associated action as

illustrated:

Events and actions are each numbered and linked together

in pairs (states). This means that when event [0] is fulfilled

(attains the value TRUE), action [0] is executed. After this,

the conditions of event [1] will be evaluated and if

evaluated TRUE, action [1] will be executed and so on.

Only one event will be evaluated at any time. If an event is

evaluated as FALSE, nothing happens (in the SLC) during

the current scan interval and no other events will be

evaluated. This means that when the SLC starts, it

evaluates event [0] (and only event [0]) each scan interval.

Only when event [0] is evaluated TRUE, will the SLC

execute action [0] and start evaluating event [1]. It is

possible to program from 1 to 20 events and actions.

When the last event / action has been executed, the

sequence starts over again from event [0] / action [0]. The

figure shows an example with three events/actions:

Starting and stopping the SLC:

Starting and stopping the SLC can be done by

selecting .On [1]. or .Off [0]. in 13-00 SL Controller Mode.

The SLC always starts in state 0 (where it evaluates event

[0]). The SLC starts when the Start Event (defined in

13-01 Start Event) is evaluated as TRUE (provided that On

[1] is selected in 13-00 SL Controller Mode). The SLC stops

when the Stop Event (13-02 Stop Event) is TRUE. 13-03 Reset

SLC resets all SLC parameters and start programming from

scratch.

3.14.2

13-0* SLC Settings

Use the SLC settings to activate, deactivate and reset the

Smart Logic Control sequence. The logic functions and

comparators are always running in the background, which

opens for separate control of digital inputs and outputs.

13-00 SL Controller Mode

Option: Function:

[0] Off Disables the Smart Logic Controller.

[1] On Enables the Smart Logic Controller.

13-01 Start Event

Option: Function:

[0] * False Select the Boolean (TRUE or FALSE)

input to activate Smart Logic Control.

False [0] enters the fixed value - FALSE

[1] True

True [1] enters the fixed value - TRUE.

[2] Running

Running [2] The motor is running.

[3] In range

In range [3] The motor is running

within the programmed current and

speed ranges set in 4-50 Warning

Current Low to 4-53 Warning Speed

High.

Parameter Descriptions FC 300 Programming Guide

3-110 MG33MD22 - VLT

®

is a registered Danfoss trademark

3

3

Loading...

Loading...