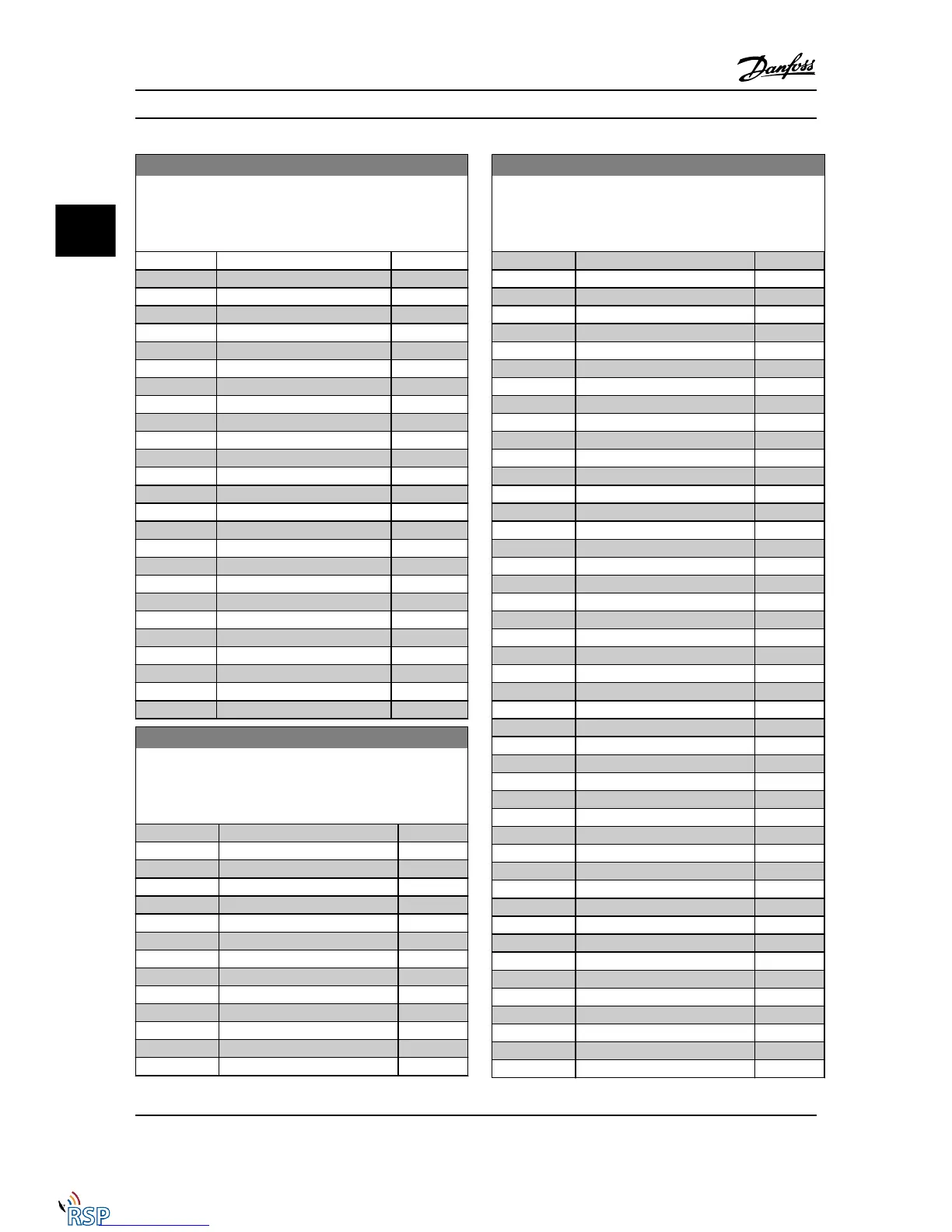

10-11 Process Data Config Write

Select the process write data for I/O assembly instances 101/151.

Elements [2] and [3] of this array can be selected. Elements [0]

and [1] of the array are fixed.

Option: Function:

[593] Pulse Out #27 Bus Control

[595] Pulse Out #29 Bus Control

[597] Pulse Out #X30/6 Bus Control

[653] Term 42 Output Bus Ctrl

[663] Terminal X30/8 Bus Control

[673] Terminal X45/1 Bus Control

[683] Terminal X45/3 Bus Control

[748] PCD Feed Forward

[890] Bus Jog 1 Speed

[891] Bus Jog 2 Speed

[1680] Fieldbus CTW 1

[1682] Fieldbus REF 1

[1685] FC Port CTW 1

[1686] FC Port REF 1

[3310] Sync Factor Master

[3311] Sync Factor Slave

[3401] PCD 1 Write to MCO

[3402] PCD 2 Write to MCO

[3403] PCD 3 Write to MCO

[3404] PCD 4 Write to MCO

[3405] PCD 5 Write to MCO

[3406] PCD 6 Write to MCO

[3407] PCD 7 Write to MCO

[3408] PCD 8 Write to MCO

[3409] PCD 9 Write to MCO

[3410] PCD 10 Write to MCO

10-12 Process Data Config Read

Select the process read data for I/O assembly instances 101/151.

Elements [2] and [3] of this array can be selected. Elements [0]

and [1] of the array are fixed.

Option: Function:

[0] * None

[15] Readout: actual setup

[1472] Legacy Alarm Word

[1473] Legacy Warning Word

[1474] Leg. Ext. Status Word

[1500] Operating Hours

[1501] Running Hours

[1502] kWh Counter

[1600] Control Word

[1601] Reference [Unit]

[1602] Reference %

[1603] Status Word

[1605] Main Actual Value [%]

[1609] Custom Readout

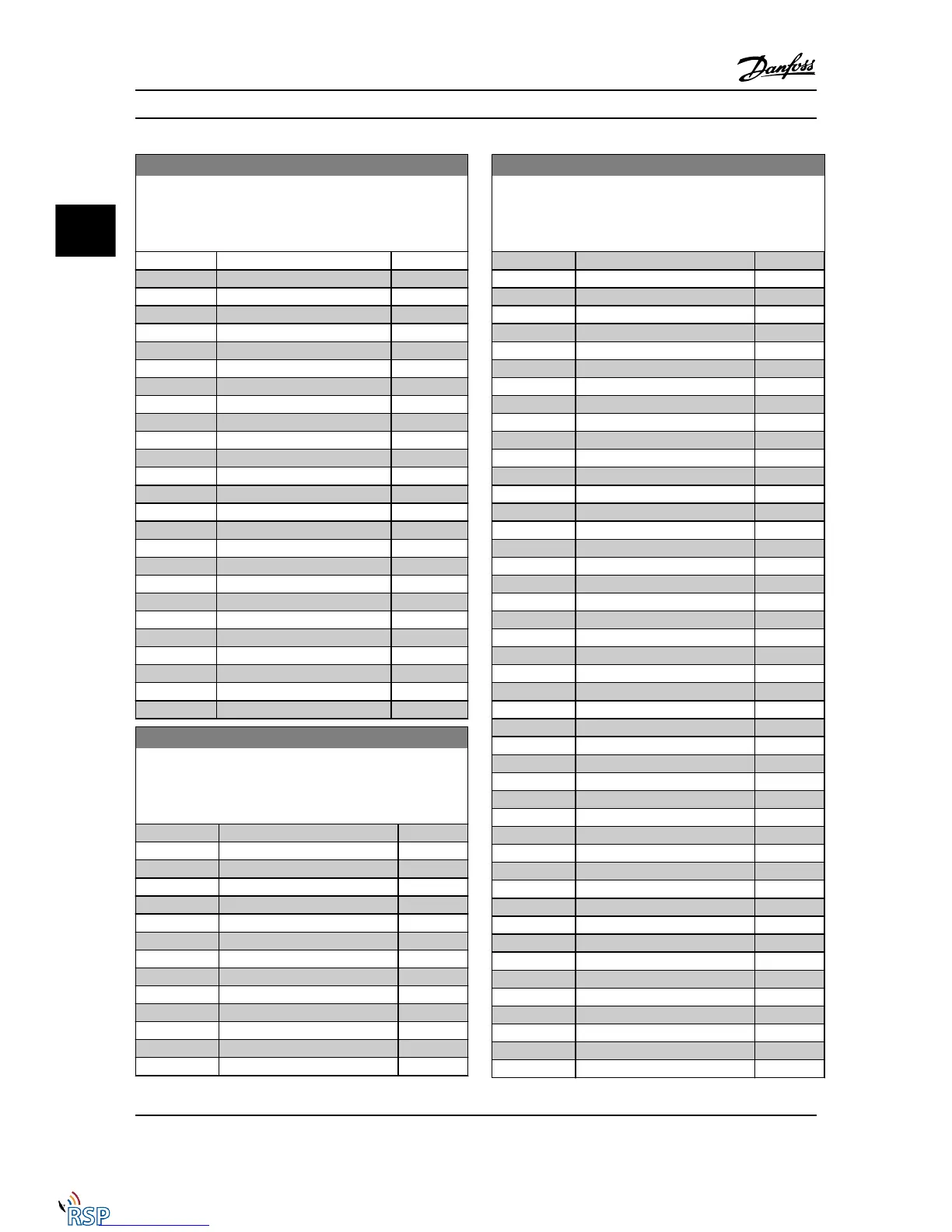

10-12 Process Data Config Read

Select the process read data for I/O assembly instances 101/151.

Elements [2] and [3] of this array can be selected. Elements [0]

and [1] of the array are fixed.

Option: Function:

[1610] Power [kW]

[1611] Power [hp]

[1612] Motor Voltage

[1613] Frequency

[1614] Motor Current

[1615] Frequency [%]

[1616] Torque [Nm]

[1617] Speed [RPM]

[1618] Motor Thermal

[1619] KTY sensor temperature

[1620] Motor Angle

[1621] Torque [%] High Res.

[1622] Torque [%]

[1625] Torque [Nm] High

[1630] DC Link Voltage

[1632] Brake Energy /s

[1633] Brake Energy /2 min

[1634] Heatsink Temp.

[1635] Inverter Thermal

[1638] SL Controller State

[1639] Control Card Temp.

[1650] External Reference

[1651] Pulse Reference

[1652] Feedback [Unit]

[1653] Digi Pot Reference

[1657] Feedback [RPM]

[1660] Digital Input

[1661] Terminal 53 Switch Setting

[1662] Analog Input 53

[1663] Terminal 54 Switch Setting

[1664] Analog Input 54

[1665] Analog Output 42 [mA]

[1666] Digital Output [bin]

[1667] Freq. Input #29 [Hz]

[1668] Freq. Input #33 [Hz]

[1669] Pulse Output #27 [Hz]

[1670] Pulse Output #29 [Hz]

[1671] Relay Output [bin]

[1672] Counter A

[1673] Counter B

[1674] Prec. Stop Counter

[1675] Analog In X30/11

[1676] Analog In X30/12

[1677] Analog Out X30/8 [mA]

[1678] Analog Out X45/1 [mA]

[1679] Analog Out X45/3 [mA]

Parameter Descriptions FC 300 Programming Guide

3-102 MG33MD22 - VLT

®

is a registered Danfoss trademark

3

3

Loading...

Loading...