3.12 Parameters: 10-** DeviceNet CAN

Fieldbus

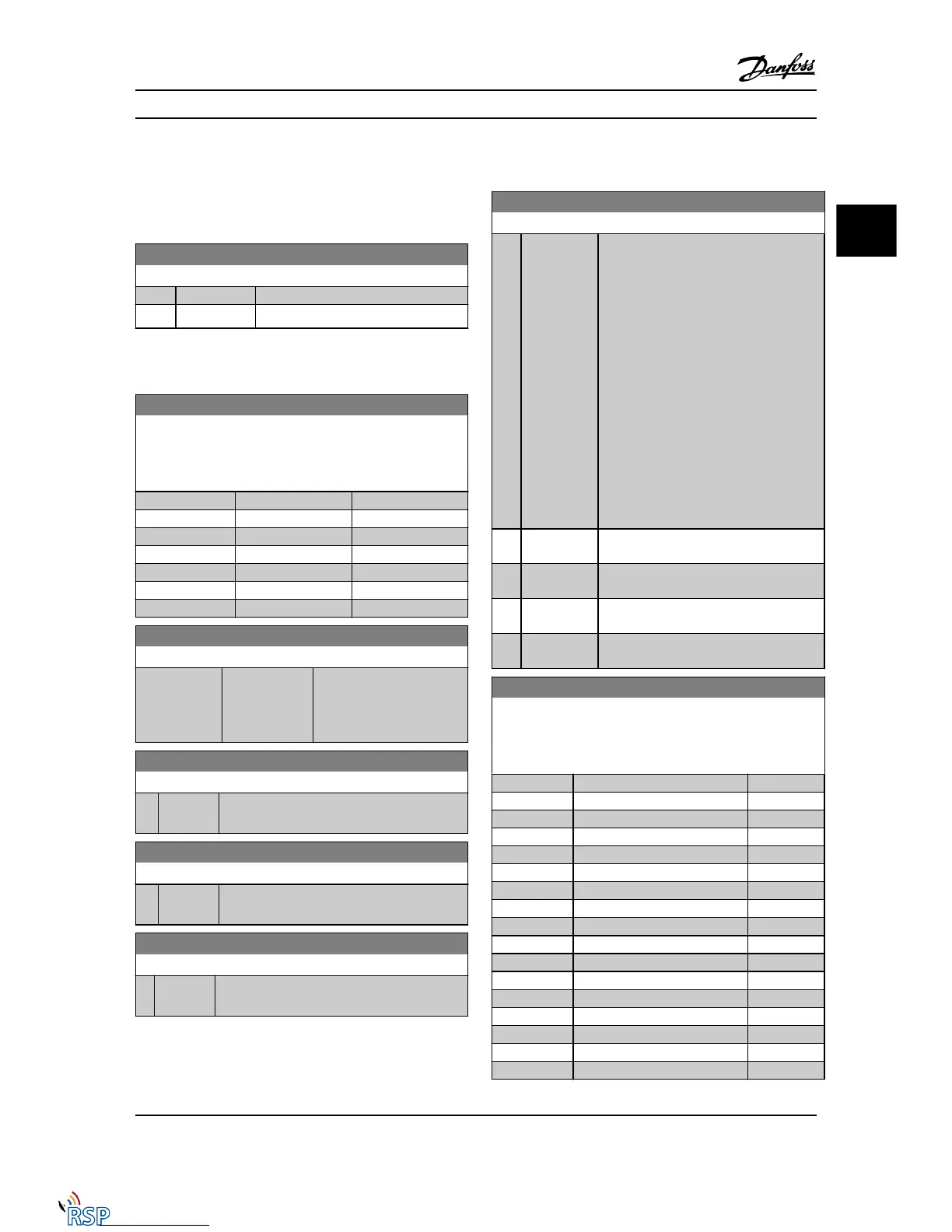

3.12.1 10-0* Common Settings

10-00 CAN Protocol

Option: Function:

[0] CANopen

[1] * DeviceNet View the active CAN protocol.

NOTE!

The options depend on installed option.

10-01 Baud Rate Select

Select the serial communication bus transmission speed. The

selection must correspond to the transmission speed of the

master and the other serial communication bus nodes.

Option: Function:

[16] 10 Kbps

[17] 20 Kbps

[18] 50 Kbps

[19] 100 Kbps

[20] * 125 Kbps

[21] 250 Kbps

[22] 500 Kbps

10-02 MAC ID

Range: Function:

Application

dependent*

[Application

dependant]

Selection of station address.

Every station connected to

the same network must have

an unambiguous address.

10-05 Readout Transmit Error Counter

Range: Function:

0 * [0 - 255 ] View the number of CAN control transmission

errors since the last power-up.

10-06 Readout Receive Error Counter

Range: Function:

0 * [0 - 255 ] View the number of CAN control receipt errors

since the last power-up.

10-07 Readout Bus Off Counter

Range: Function:

0* [0 - 255 ] View the number of Bus Off events since the last

power-up.

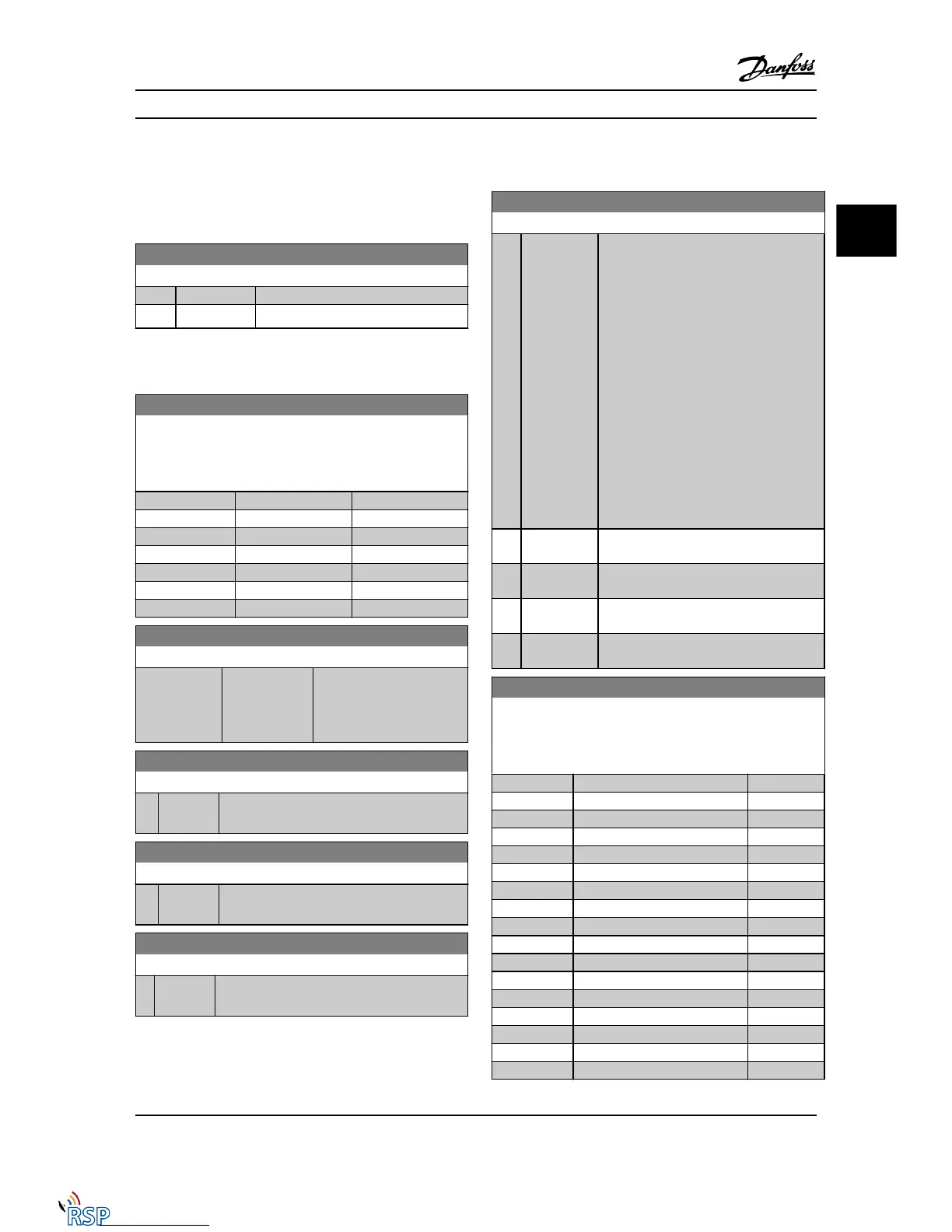

3.12.2 10-1* DeviceNet

10-10 Process Data Type Selection

Option: Function:

Select the Instance (message) for data

transmission. The instances available are

dependent upon the setting of 8-10 Control

Profile.

When 8-10 Control Profile is set to [0] FC

profile, 10-10 Process Data Type Selection

options [0] and [1] are available.

When 8-10 Control Profile is set to [5] ODVA,

10-10 Process Data Type Selection options [2]

and [3] are available.

Instances 100/150 and 101/151 are Danfoss-

specific. Instances 20/70 and 21/71 are

ODVA-specific AC Drive profiles.

For guidelines in message selection, please

refer to the DeviceNet Instruction Manual.

Note that a change to this parameter will

be executed immediately.

[0] * INSTANCE

100/150

[1] INSTANCE

101/151

[2] INSTANCE

20/70

[3] INSTANCE

21/71

10-11 Process Data Config Write

Select the process write data for I/O assembly instances 101/151.

Elements [2] and [3] of this array can be selected. Elements [0]

and [1] of the array are fixed.

Option: Function:

[0] * None

[302] Minimum Reference

[303] Maximum Reference

[312] Catch up/slow Down Value

[341] Ramp 1 Ramp up Time

[342] Ramp 1 Ramp Down Time

[351] Ramp 2 Ramp up Time

[352] Ramp 2 Ramp down Time

[380] Jog Ramp Time

[381] Quick Stop Ramp Time

[411] Motor Speed Low Limit [RPM]

[412] Motor Speed Low Limit [Hz]

[413] Motor Speed High Limit [RPM]

[414] Motor Speed High Limit [Hz]

[416] Torque Limit Motor Mode

[417] Torque Limit Generator Mode

[590] Digital & Relay Bus Control

Parameter Descriptions FC 300 Programming Guide

MG33MD22 - VLT

®

is a registered Danfoss trademark 3-101

3

3

Loading...

Loading...