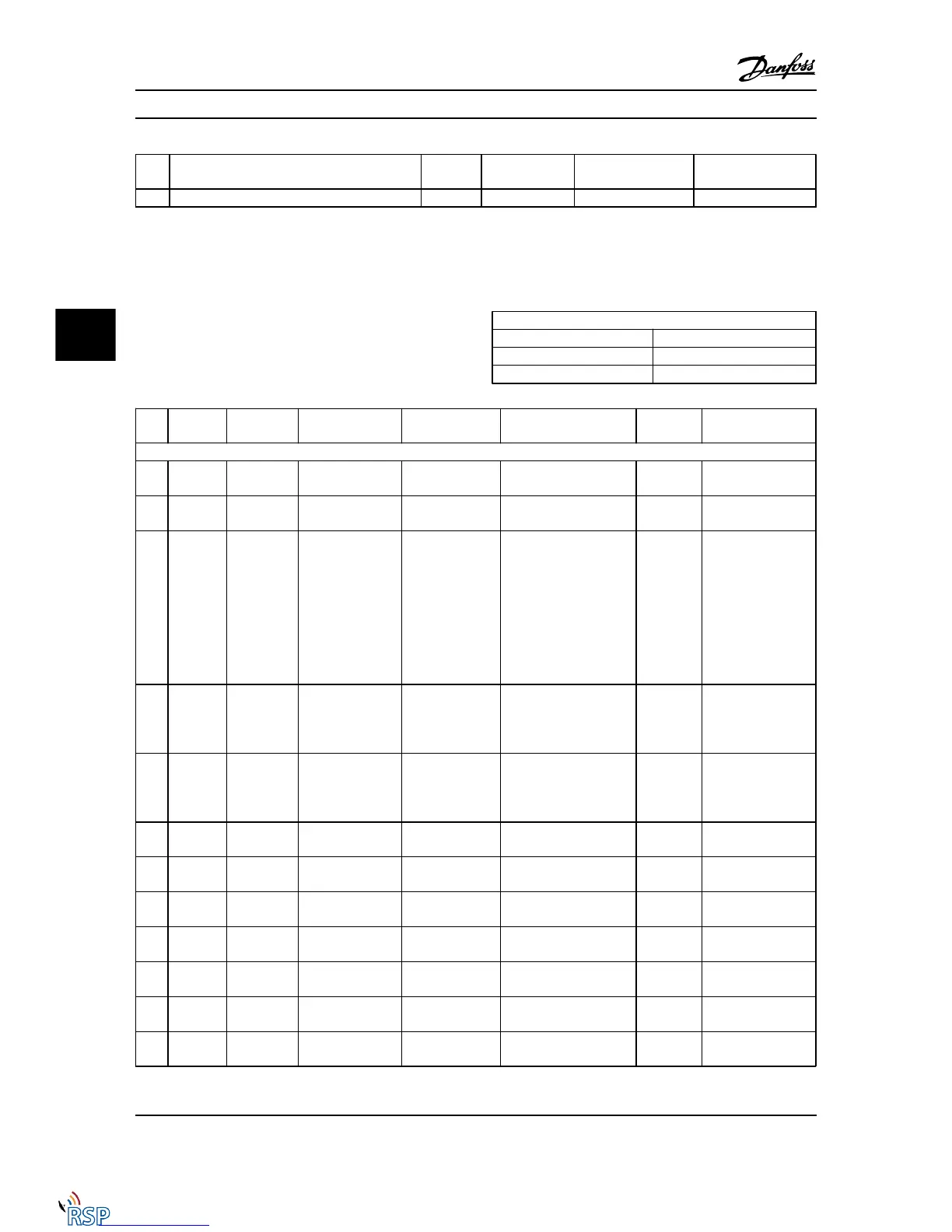

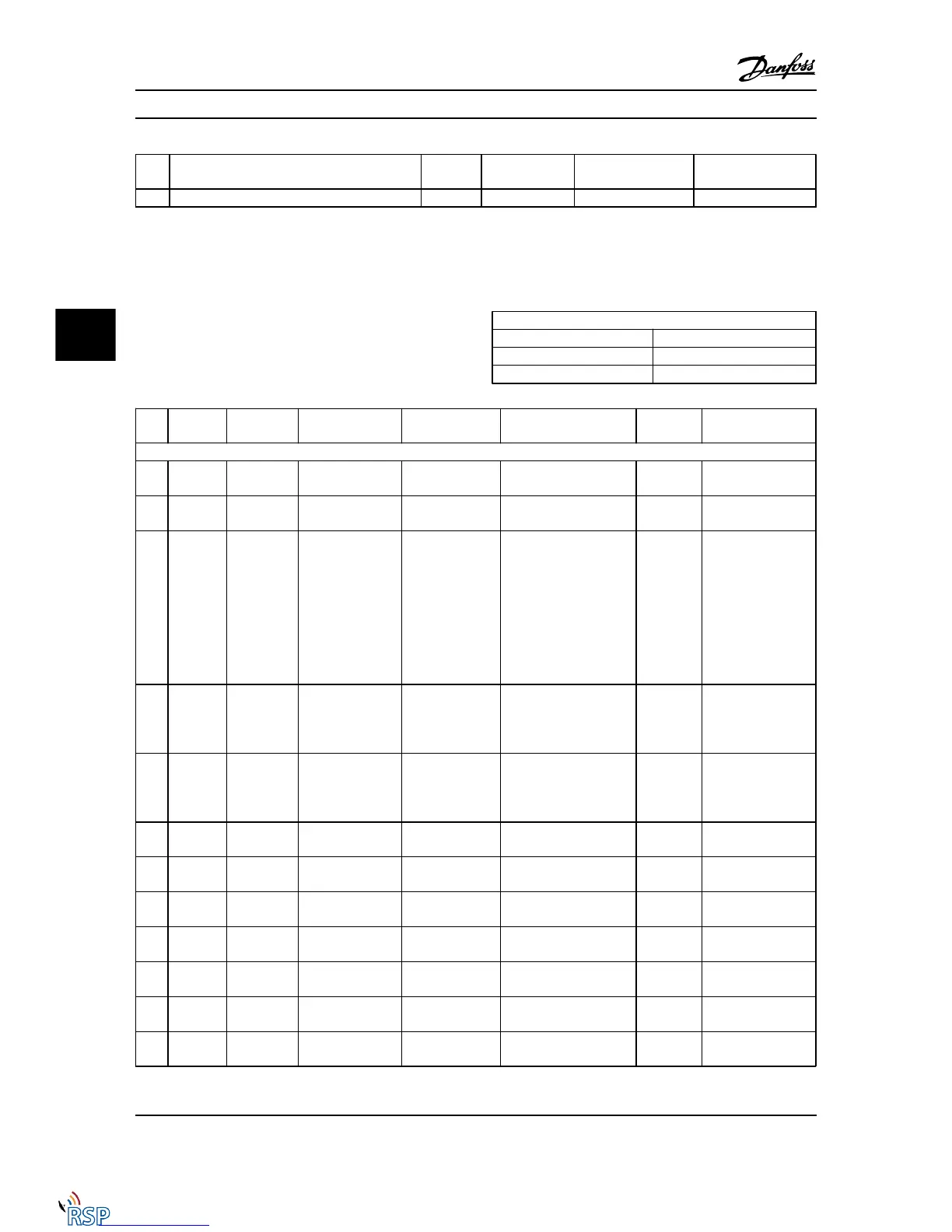

No. Description Warning Alarm/Trip Alarm/Trip Lock Parameter

Reference

251 New Type Code X X

Table 5.1 Alarm/Warning code list

(X) Dependent on parameter

1) Cannot be Auto reset via 14-20 Reset Mode

A trip is the action when an alarm has appeared. The trip

will coast the motor and can be reset by pressing the reset

button or make a reset by a digital input (parameter group

5-1* [1]). The original event that caused an alarm cannot

damage the Adjustable frequency drive or cause

dangerous conditions. A trip lock is an action when an

alarm occurs that may cause damage to theAdjustable

frequency drive or connected parts. A trip lock situation

can only be reset by power cycling.

LED indication

Warning yellow

Alarm flashing red

Trip locked yellow and red

Bit Hex Dec Alarm Word Alarm Word 2 Warning Word Warning

Word 2

Extended

Status Word

Alarm Word Extended Status Word

0 00000001 1 Brake Check (A28) ServiceTrip, Read/

Write

Brake Check (W28) reserved Ramping

1 00000002 2 Heatsink temp.

(A29)

ServiceTrip,

(reserved)

Heatsink temp. (W29) reserved AMA Running

2 00000004 4 Ground Fault (A14) ServiceTrip,

Typecode/

Sparepart

Ground Fault (W14) reserved Start CW/CCW

NOT start_possible

start_possible is

active, when the DI

selections [12] OR

[13] are active and

the requested

direction matches the

reference sign.

3 00000008 8 Ctrl.Card Temp

(A65)

ServiceTrip,

(reserved)

Ctrl.Card Temp (W65) reserved Slow-down

slow-down command

active, e.g., via CTW

bit 11 or DI

4 00000010 16 Ctrl. Word TO (A17) ServiceTrip,

(reserved)

Ctrl. Word TO (W17) Catch Up

catch up command

active, e.g., via CTW

bit 12 or DI

5 00000020 32 Overcurrent (A13) reserved Overcurrent (W13) reserved Feedback High

feedback > p4-57

6 00000040 64 Torque Limit (A12) reserved Torque Limit (W12) reserved Feedback Low

feedback < p4-56

7 00000080 128 Motor Th Over

(A11)

reserved Motor Th Over (W11) reserved Output Current High

current > p4-51

8 00000100 256 Motor ETR Over

(A10)

reserved Motor ETR Over (W10) reserved Output Current Low

current < p4-50

9 00000200 512 Inverter Overld.

(A9)

reserved Inverter Overld (W9) reserved Output Freq High

speed > p4-53

10 00000400 1,024 DC under-volt (A8) reserved DC under-volt (W8) Output Freq Low

speed < p4-52

11 00000800 2,048 DC overvoltage

(A7)

reserved DC overvoltage (W7) Brake Check OK

brake test NOT ok

Troubleshooting FC 300 Programming Guide

5-4 MG33MD22 - VLT

®

is a registered Danfoss trademark

55

Loading...

Loading...