Usually the resolver feedback is used as motor feedback

from permanent magnet motors with 1-01 Motor Control

Principle set to Flux with motor feedback.

Resolver parameters cannot be adjusted while the motor is

running.

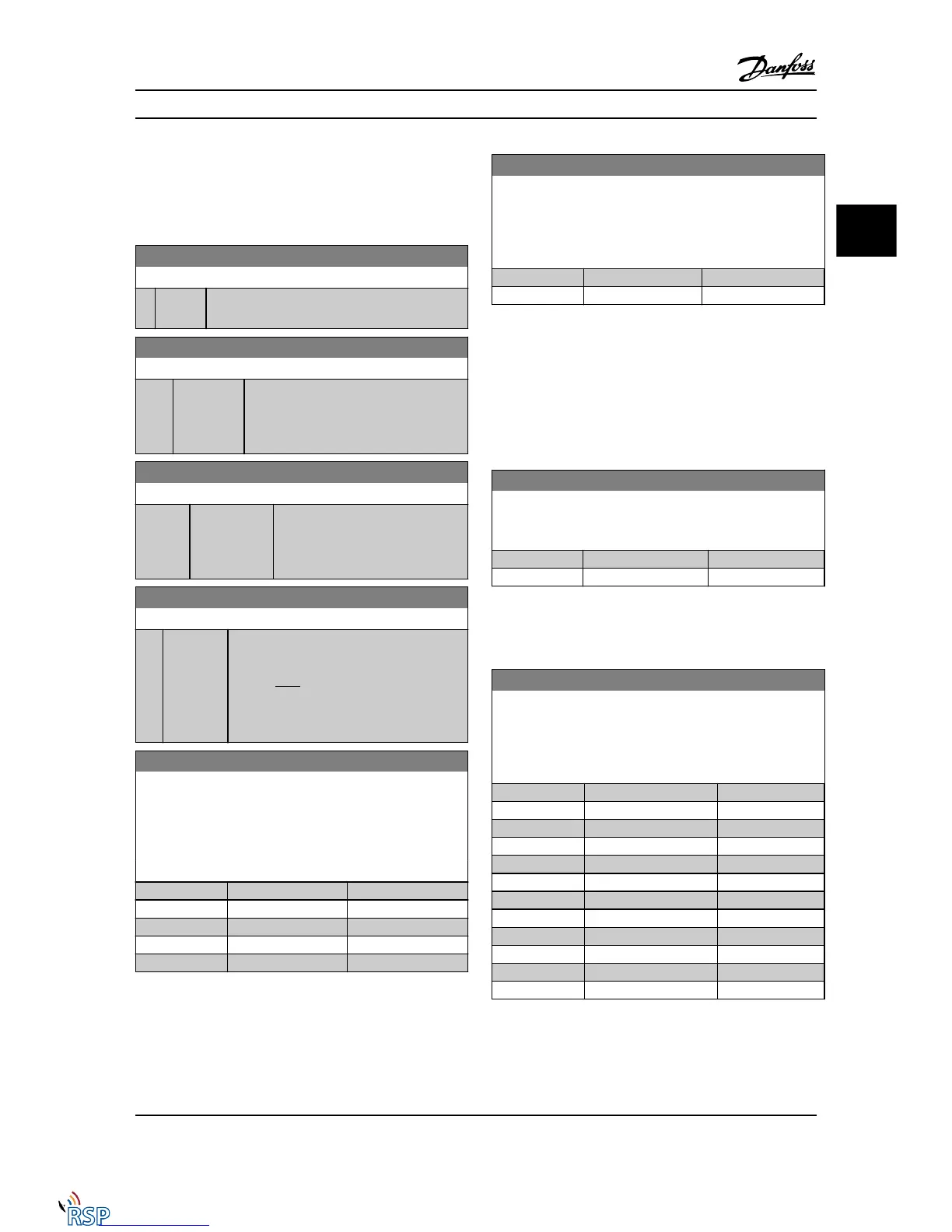

17-50 Poles

Range: Function:

2* [2 - 2 ] Set the number of poles on the resolver.

The value is stated in the data sheet for resolvers.

17-51 Input Voltage

Range: Function:

7.0 V* [2.0 - 8.0 V] Set the input voltage to the resolver. The

voltage is stated as an RMS value.

The value is stated in the data sheet for

resolvers.

17-52 Input Frequency

Range: Function:

10.0 kHz* [2.0 - 15.0

kHz]

Set the input frequency to the

resolver.

The value is stated in the data sheet

for resolvers.

17-53 Transformation Ratio

Range: Function:

0.5* [0.1 - 1.1 ] Set the transformation ratio for the resolver.

The transformation ration is:

T

ratio

=

V

Out

V

In

The value is stated in the data sheet for

resolvers.

17-56 Encoder Sim. Resolution

Set the resolution and activate the encoder emulation function

(generation of encoder signals from the measured position from

a resolver). Needed when necessary to transfer the speed or

position information from one drive to another. To disable the

function, select [0].

Option: Function:

[0] * Disabled

[1] 512

[2] 1024

[3] 2048

[4] 4096

17-59 Resolver Interface

Activate the MCB 103 resolver option when the resolver

parameters are selected.

To avoid damage to resolvers, 17-50 Poles – 17-53 Transformation

Ratio must be adjusted before activating this parameter.

Option: Function:

[0] * Disabled

[1] Enabled

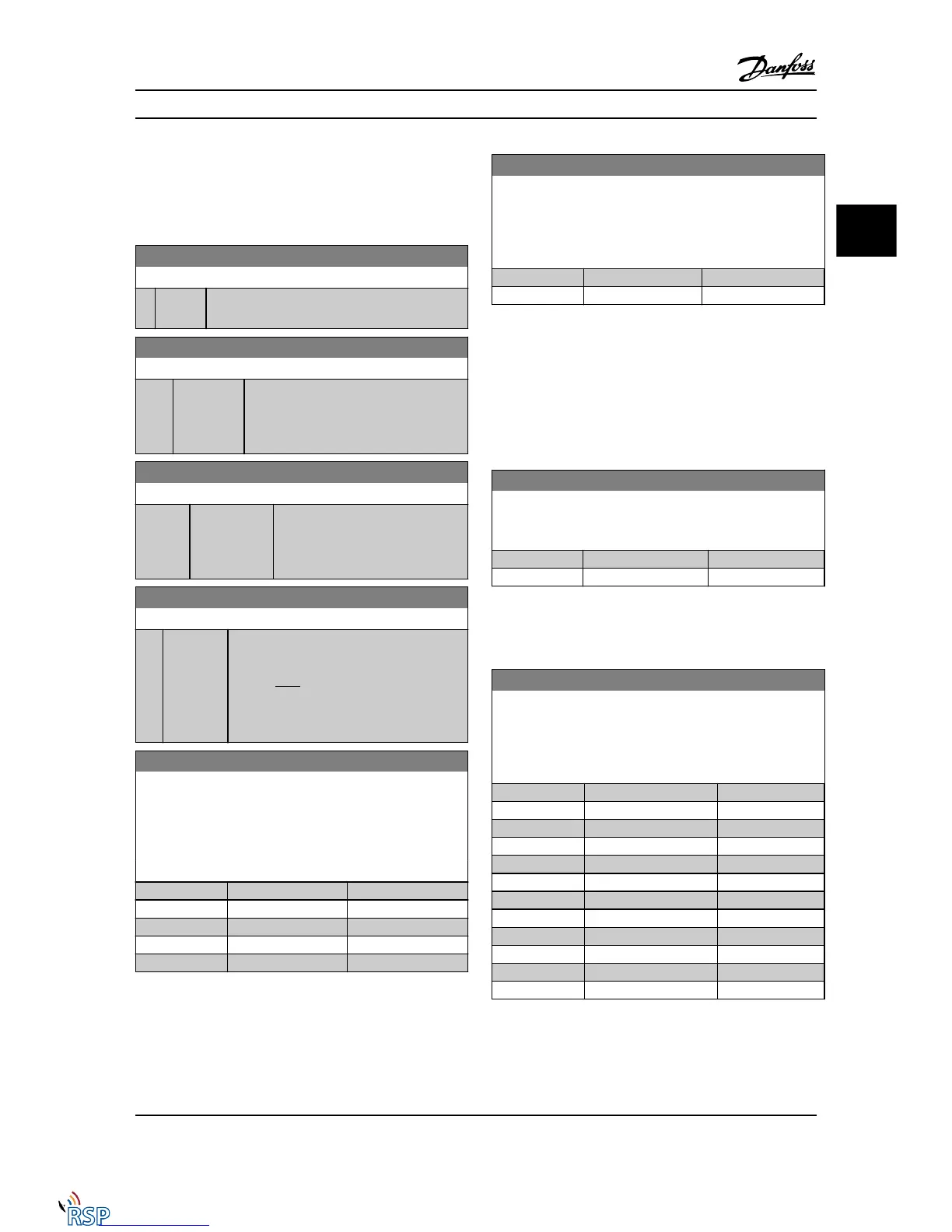

3.18.4 17-6* Monitoring and Application

This parameter group is used for selecting additional

functions when the MCB 102 Encoder option or MCB 103

Resolver option is fitted into option slot B as speed

feedback.

Monitoring and application parameters cannot be adjusted

while the motor is running.

17-60 Feedback Direction

Change the detected encoder rotation direction without

changing the wiring to the encoder.

Option: Function:

[0] * Clockwise

[1] Counter clockwise

NOTE!

This parameter cannot be adjusted while the motor is

running.

17-61 Feedback Signal Monitoring

Select which reaction the Adjustable frequency drive should take

if a faulty encoder signal is detected.

The encoder function in 17-61 Feedback Signal Monitoring is an

electrical check of the hardware circuit in the encoder system.

Option: Function:

[0] Disabled

[1] * Warning

[2] Trip

[3] Jog

[4] Freeze Output

[5] Max Speed

[6] Switch to Open Loop

[7] Select Setup 1

[8] Select Setup 2

[9] Select Setup 3

[10] Select Setup 4

[11] stop & trip

Parameter Descriptions FC 300 Programming Guide

MG33MD22 - VLT

®

is a registered Danfoss trademark 3-149

3

3

Loading...

Loading...