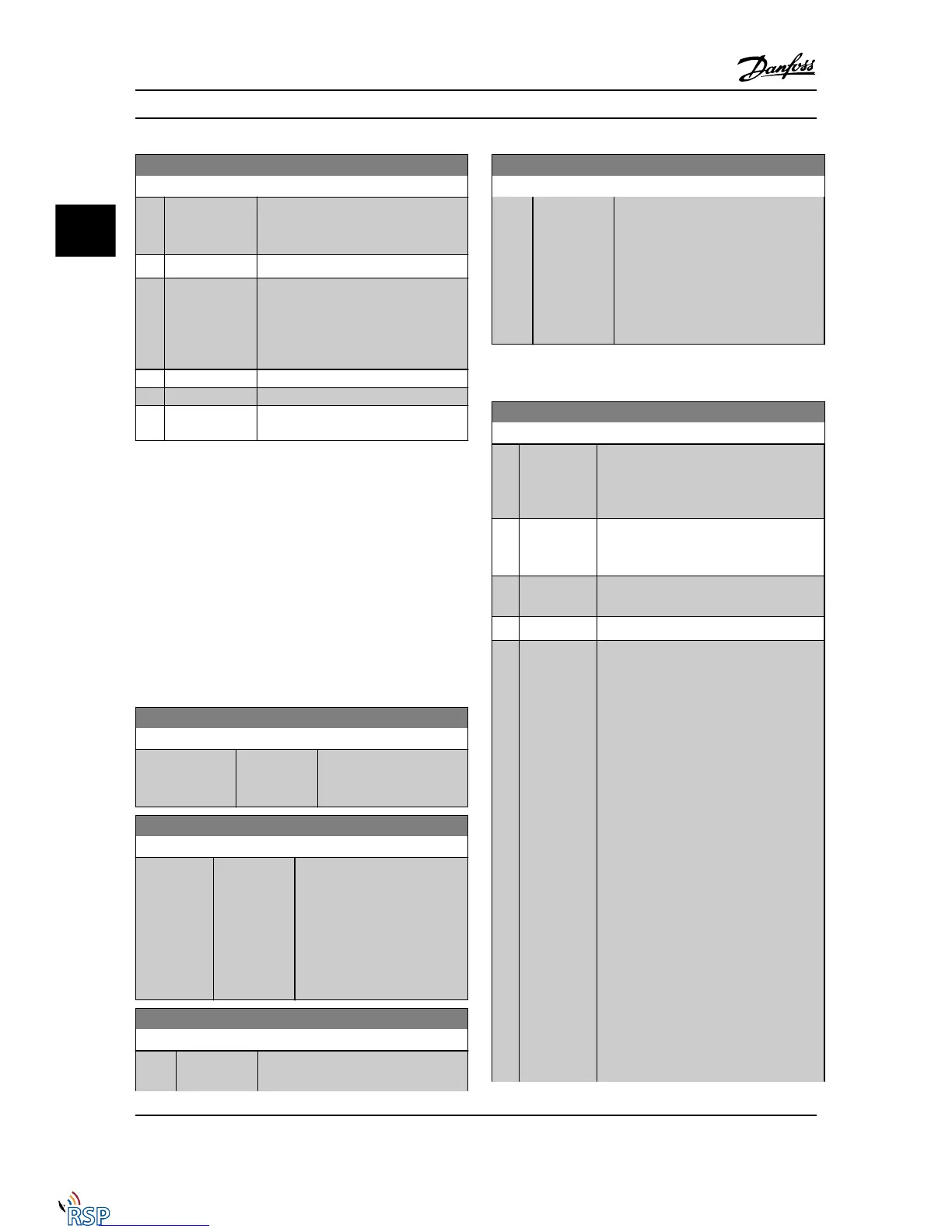

1-73 Flying Start

Option: Function:

This function makes it possible to catch

a motor that is spinning freely due to a

line drop-out.

[0] * Disabled No function

[1] Enabled Enables the Adjustable frequency drive

to “catch” and control a spinning motor.

When 1-73 Flying Start is enabled,

1-71 Start Delay and 1-72 Start Function

have no function.

[2] Enabled Always

[3] Enabled Ref. Dir.

[4] Enab. Always

Ref. Dir.

NOTE!

This parameter cannot be adjusted while motor is running.

NOTE!

This function is not recommended for hoisting

applications.

For power levels above 75 hp [55 kW], flux mode must be

used to achieve the best performance.

NOTE!

To obtain the best flying start performance the advanced

motor data, parameters 1-30 through 1-35, must be

correct.

1-74 Start Speed [RPM]

Range: Function:

Application

dependent*

[0 - 600 RPM] This parameter can be used

for hoist applications (cone

rotor).

1-75 Start Speed [Hz]

Range: Function:

Application

dependent*

[Application

dependant]

This parameter can be used for

hoist applications (cone rotor).

Set a motor start speed. After the

start signal, the output speed

leaps to set value. Set the start

function in 1-72 Start Function to

[3], [4] or [5], and set a start

delay time in 1-71 Start Delay.

1-76 Start Current

Range: Function:

0.00

A*

[Application

dependant]

Some motors, e.g., cone rotor motors,

need extra current/starting speed to

1-76 Start Current

Range: Function:

disengage the rotor. To obtain this

boost, set the required current in

1-76 Start Current. Set 1-74 Start Speed

[RPM]. Set 1-72 Start Function to [3] or

[4], and set a start delay time in

1-71 Start Delay.

This parameter can be used for hoist

applications (cone rotor).

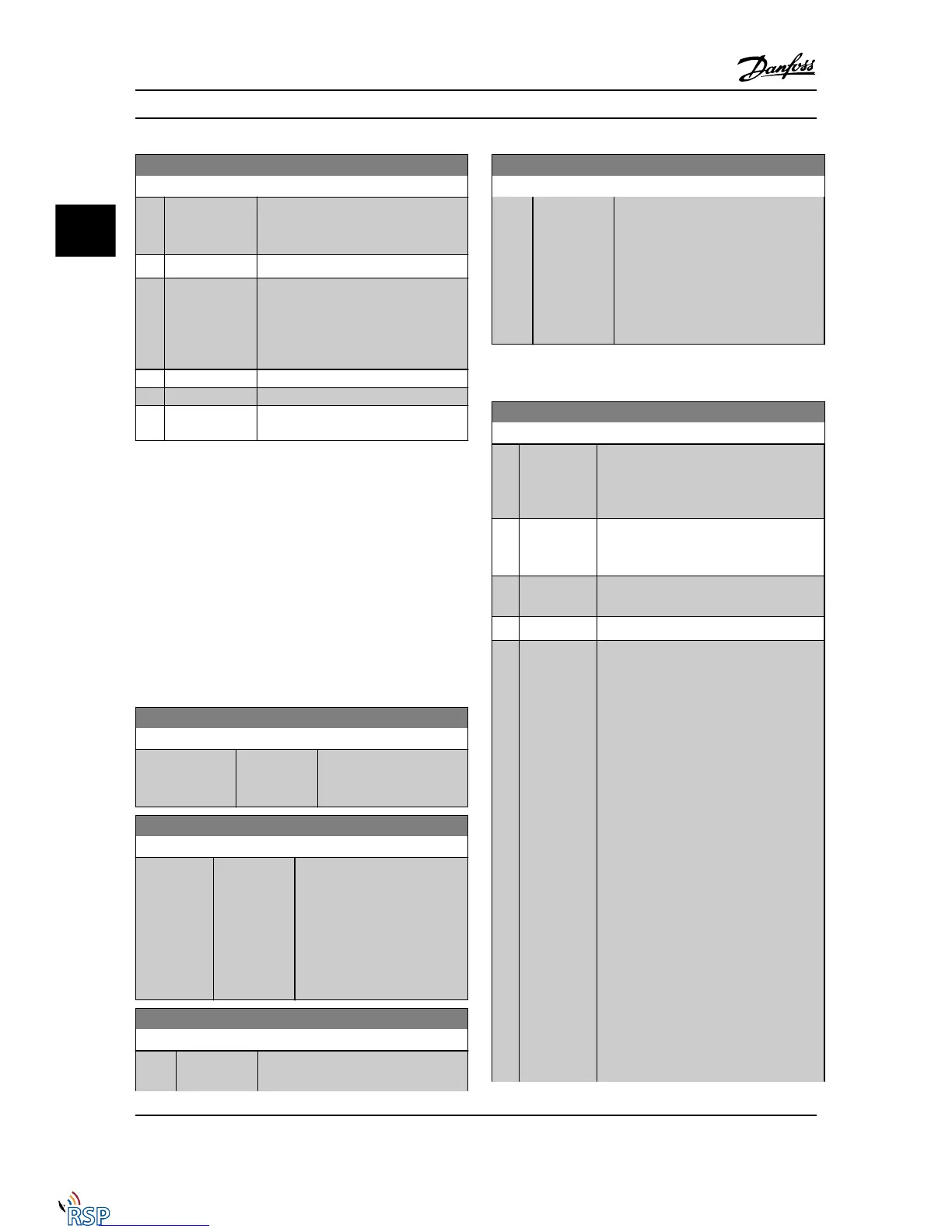

3.3.8 1-8* Stop Adjustments

1-80 Function at Stop

Option: Function:

Select the Adjustable frequency drive

function after a stop command or after the

speed is ramped down to the settings in

1-81 Min Speed for Function at Stop [RPM].

[0]

*

Coast Leaves motor in free mode. The motor is

disconnected from the Adjustable frequency

drive.

[1] DC hold Energizes motor with a DC holding current

(see 2-00 DC Hold Current).

[2] Motor check Checks if a motor has been connected.

[3] Pre-

magnetizing

Builds up a magnetic field while the motor

is stopped. This allows the motor to

produce torque quickly at subsequent start

commands (asynchronous motors only). This

pre-magnetizing function does not help the

very first start command. Two different

solutions are available to pre-magnetize the

machine for the first start command:

1. Start the Adjustable frequency

drive with a 0RPM reference and

wait 2 to 4 rotor time constants

(see below) before increasing the

speed reference.

2a. Set 1-71 Start Delay to the

desired pre-mag time (2 to 4 rotor

time constants - see below).

2b. Set 1-72 to either [0] DC-hold

or [1] DC Brake.

Set the DC hold or DC brake

current magnitude (2-00 or 2-01) to

be equal to I_pre-mag = Unom /

(1.73 x Xh)

Sample rotor time constants =

(Xh+X2) / (6.3*Freq_nom*Rr)

Parameter Descriptions FC 300 Programming Guide

3-22 MG33MD22 - VLT

®

is a registered Danfoss trademark

3

3

Loading...

Loading...