16-85 FC Port CTW 1

Range: Function:

0 * [0 - 65535 ] View the two-byte control word (CTW)

received from the bus master. Interpretation

of the control word depends on the Serial

communication bus option installed and the

control word profile selected in 8-10 Control

Profile.

16-86 FC Port REF 1

Range: Function:

0 * [-200 -

200 ]

View the two-byte status word (STW) sent to

the bus master. Interpretation of the status

word depends on the serial communication

bus option installed and the control word

profile selected in 8-10 Control Profile.

3.17.6 16-9* Diagnosis Readouts

16-90 Alarm Word

Range: Function:

0 * [0 - 4294967295 ] View the alarm word sent via the serial

communication port in hex code.

16-91 Alarm Word 2

Range: Function:

0* [0 - 4294967295 ] View the alarm word sent via the serial

communication port in hex code.

16-92 Warning Word

Range: Function:

0 * [0 - 4294967295 ] View the warning word sent via the

serial communication port in hex code.

16-93 Warning Word 2

Range: Function:

0* [0 - 4294967295 ] View the warning word sent via the serial

communication port in hex code.

16-94 Ext. Status Word

Range: Function:

0* [0 - 4294967295 ] Returns the extended warning word sent

via the serial communication port in hex

code.

16-95 Ext. Status Word 2

Range: Function:

0 * [0 - 4294967295 ] Returns the extended warning word 2

sent via the serial communication port

in hex code.

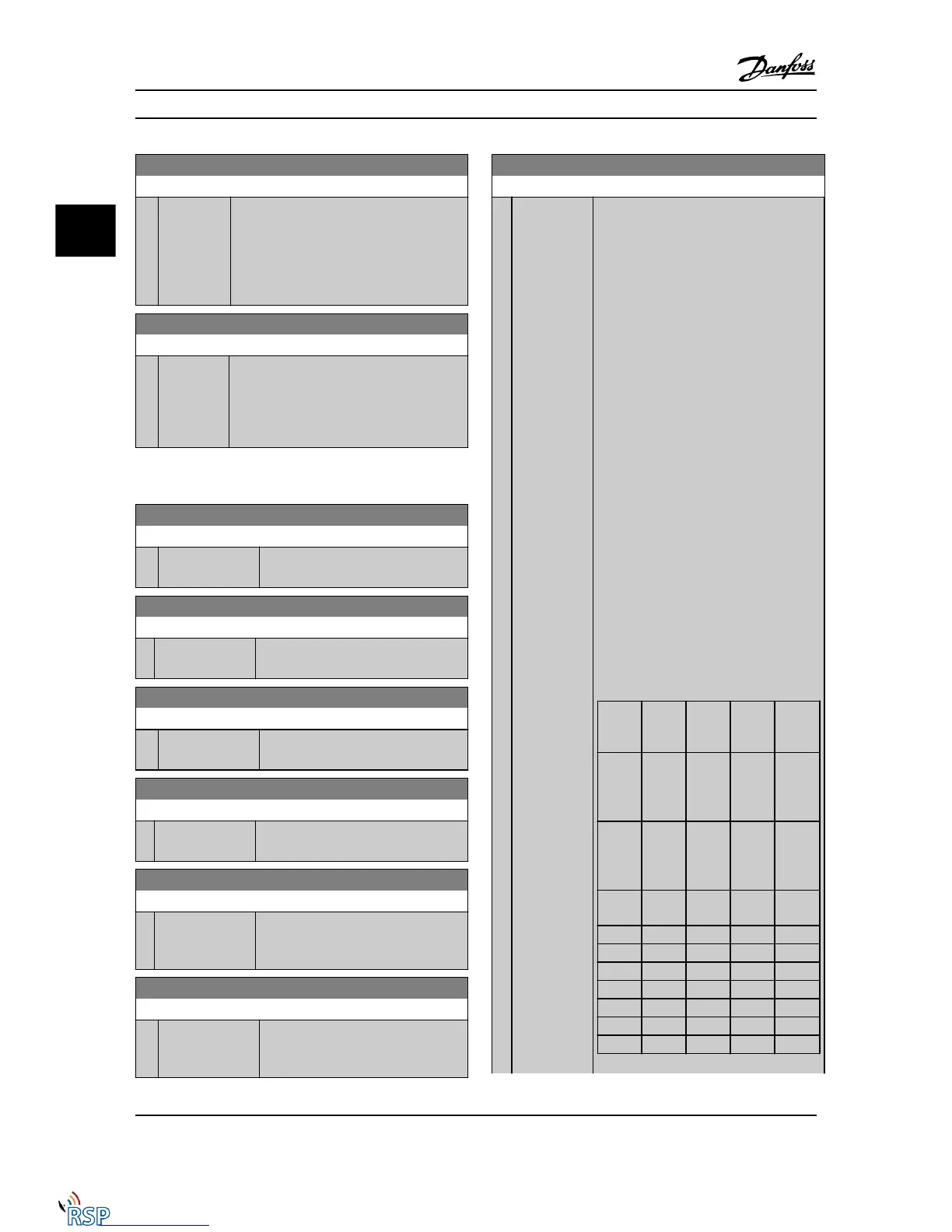

16-96 Maintenance Word

Range: Function:

0

*

[0 -

4294967295 ]

Readout of the Preventive Maintenance

Word. The bits reflect the status for the

programmed preventive maintenance events

in parameter group 23-1*. 13 bits represent

combinations of all the possible items:

•

Bit 0: Motor bearings

•

Bit 1: Pump bearings

•

Bit 2: Fan bearings

•

Bit 3: Valve

•

Bit 4: Pressure transmitter

•

Bit 5: Flow transmitter

•

Bit 6: Temperature transmitter

•

Bit 7: Pump seals

•

Bit 8: Fan belt

•

Bit 9: Filter

•

Bit 10: Drive cooling fan

•

Bit 11: Drive system health check

•

Bit 12: Warranty

•

Bit 13: Maintenance Text 0

•

Bit 14: Maintenance Text 1

•

Bit 15: Maintenance Text 2

•

Bit 16: Maintenance Text 3

•

Bit 17: Maintenance Text 4

Positio

n 4⇒

Valve Fan

bearing

s

Pump

bearing

s

Motor

bearing

s

Positio

n 3 ⇒

Pump

seals

Temper

ature

transmi

tter

Flow

transmi

tter

Pressur

e

transmi

tter

Positio

n 2 ⇒

Drive

system

health

check

Drive

cooling

fan

Filter Fan

belt

Positio

n 1⇒

Warrant

y

0

hex

- - - -

1

hex

- - - +

2

hex

- - + -

3

hex

- - + +

4

hex

- + - -

5

hex

- + - +

6

hex

- + + -

Parameter Descriptions FC 300 Programming Guide

3-146 MG33MD22 - VLT

®

is a registered Danfoss trademark

3

3

Loading...

Loading...