PROTOCOL INDEX EXAMPLES

PRODUCT REFERENCE GUIDE

149

7. Enter a Header and Terminator for the incoming message from the scale in the

fields provided. Use the

“The Text Entry Tool” on page 81 to create the Header

and Terminator, in this example <STX> and <ETX>.

8. Select a length for the message from the Length Type drop-down list. In this exam-

ple Variable Length is selected.

9.

Enter NoScale for t

he No Index String. This means “NoScale” will be attached to

the outgoing host message if nothing is received from the scale.

10. Select Trailing from the Refe

rence Edge drop-down list. This indicates the back/

trailing edge of the box is the reference point. Trailing is the normal setting for a

message from scale.

11. In the Dis

tance

to Trigger Line, enter the measured distance from the trigger to

the expected scale transmission location on the conveyor belt. This distance will

have been set up in the scale configuration. This parameter specifies the distance

from the Trigger Line (Trigger Source) to the expected receiving point of the Proto-

col Index. It is used together with the Minimum Distance betw

een Two Consecu-

tive Parcels parameter to assign the Protocol Index information to the correct

pack.

12. Select Upstre

am or Downstream from the Distance to Trigger Line State.

13. Enter a distance in the Min Distance be

tween Two Consecutive Objects text field.

This specifies the minimum distance (in mm) between two consecutive packages.

It is used to compensate for imprecision in the Distance from Protocol Index to

Trigger Line parameter by virtually lengthening the package.

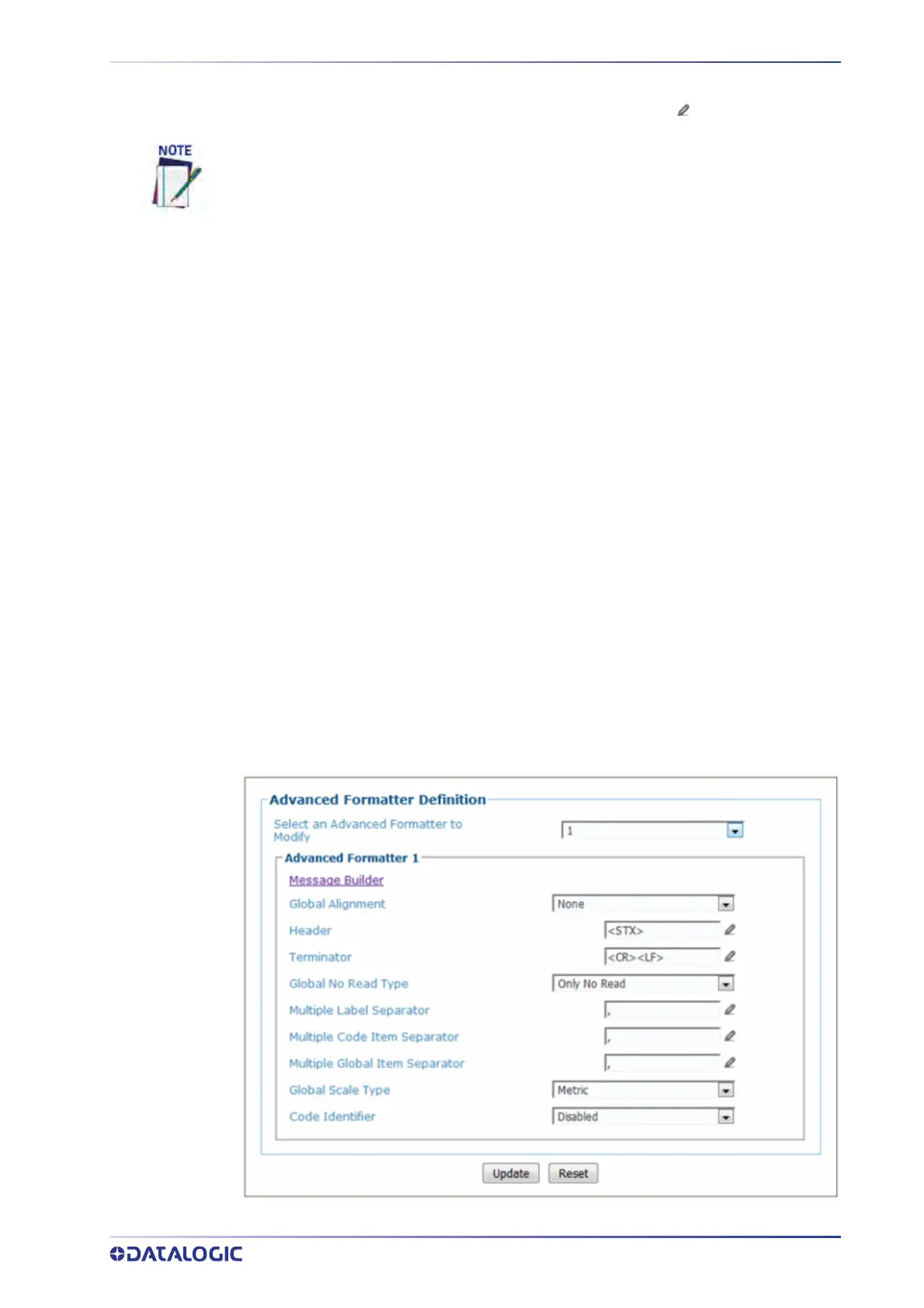

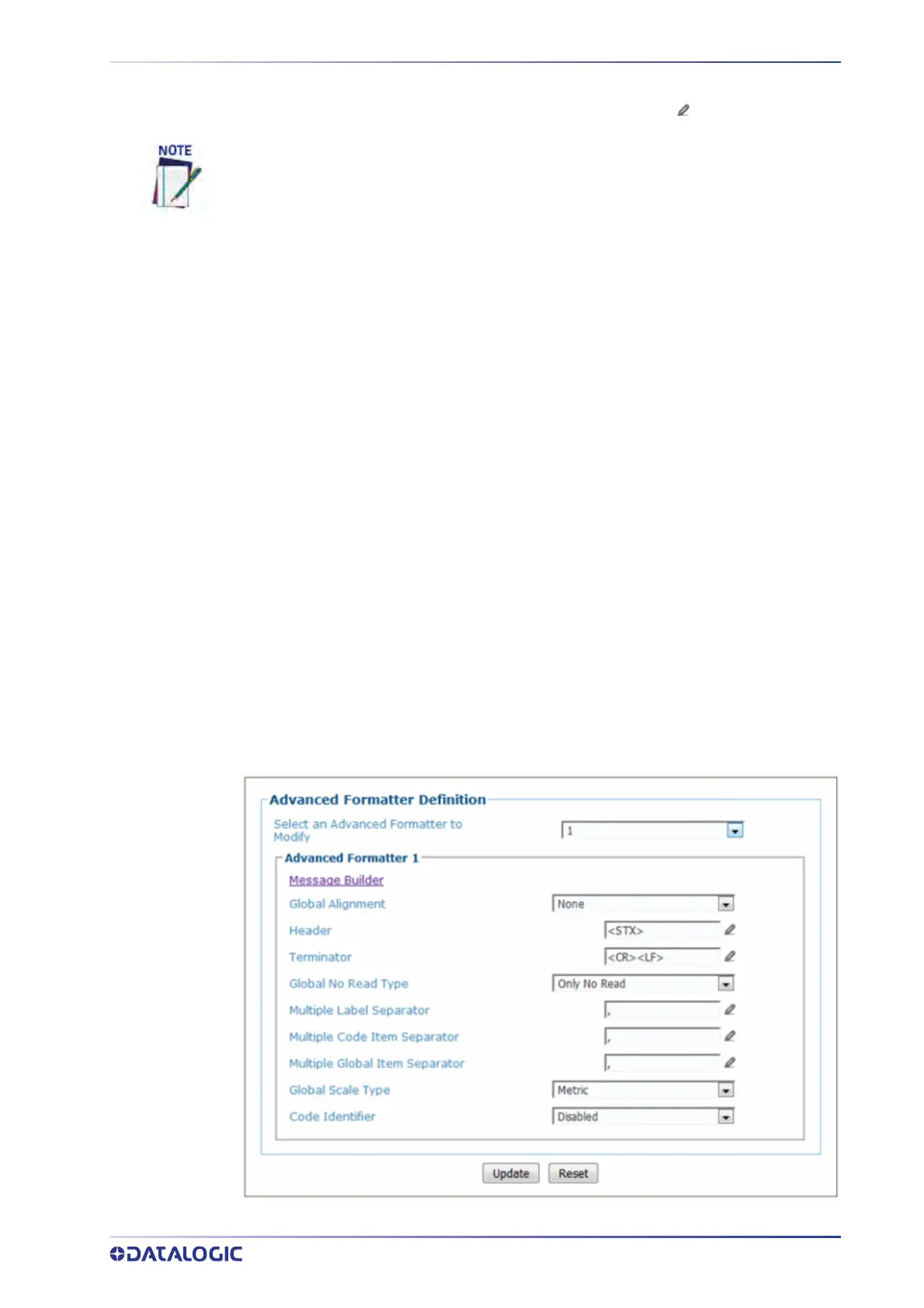

Configuration Host Message with Protocol Index

Navigate to Modify Settings | Global Settings | Output Format | Advanced Formatter.

the Advanced formatter window opens

The header and terminator must match the Protocol Index source, in this case, the

scale structures.

Loading...

Loading...