INTRODUCTION

8

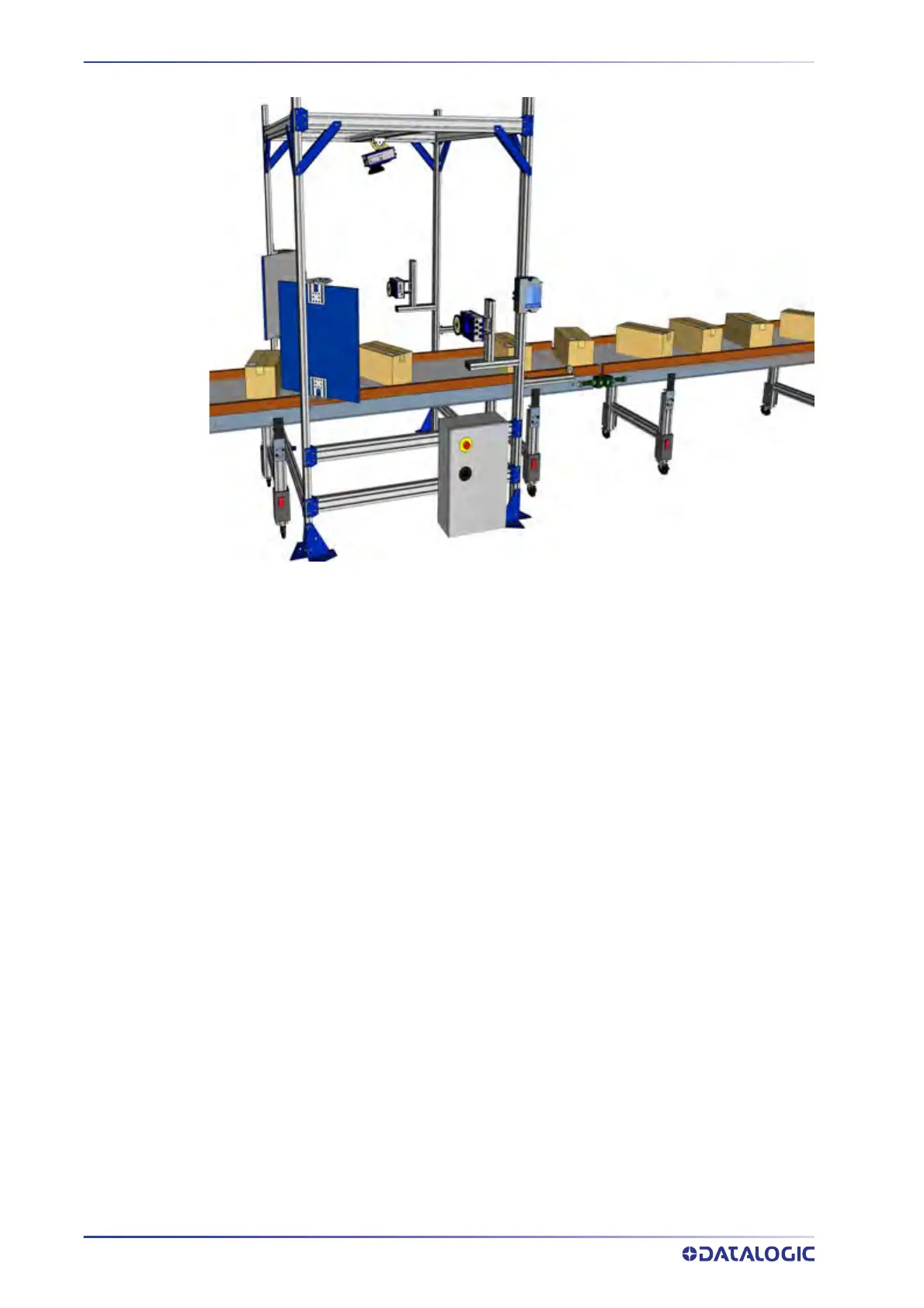

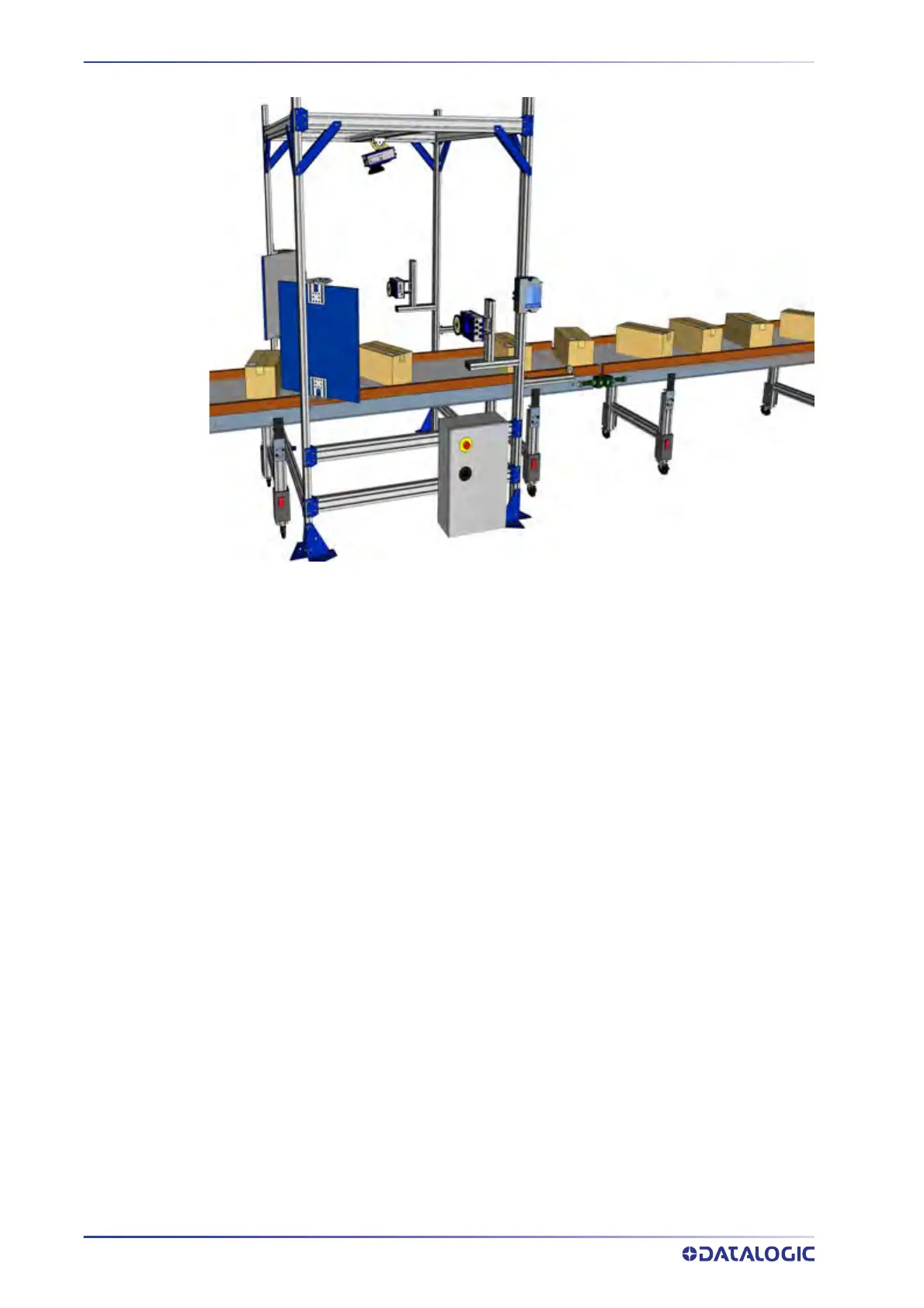

AV500/AV900 2D CAMERA

Image Acquisition

The AV500/AV900 contains both the acquisition device or “imager,” which works in

strict real time to acquire the best possible images and the decoding device or

“decoder” in one chassis. These parts of the AV500/AV900 interpret the data received.

The camera can use several kinds of external sensors:

• Speed Sensor: If mo

unted over moving conveyor, the camera needs to know the

speed of the objects to be acquired. The speed sensor is usually an encoder/

tachometer connected to the belt, or an internal software tachometer.

• Height/Side Position Sensor: The fo

cusing position is computed by the camera

based on the position of the parcel measured by a height sensor. Sensors may be a

DM3610 Dimensioner, AREAscan™ DS2 Light Array or S85.

• Trigger Source: In

multiple camera systems, each package has to be uniquely iden-

tified by all the cameras. For this reason, all of the cameras in a reading station

share a unique trig

ger source.

All the sensors are connected to the Controller camera that interprets the information

and distribut

es it to the Client cameras.The start and stop of an acquisition are triggered

by a start/stop event generated by the trigger device (position sensor, photo sensor,

read now signal). The acquisition of a package doesn’t start when the trigger source

detects it, but with a certain delay depending on:

• the distance between the trigger device and the view line at belt level

• the view line angle (alpha) of the camera

• the speed of the object

• the height of the package

Based on the AV500/AV900 mounting position,

the unit tries to

acquire one (reading

angle alpha = 15°) or two faces of the parcel (alpha = +/-45°).

Loading...

Loading...