198

zTroubleshooting Guide

chap.6

(17)

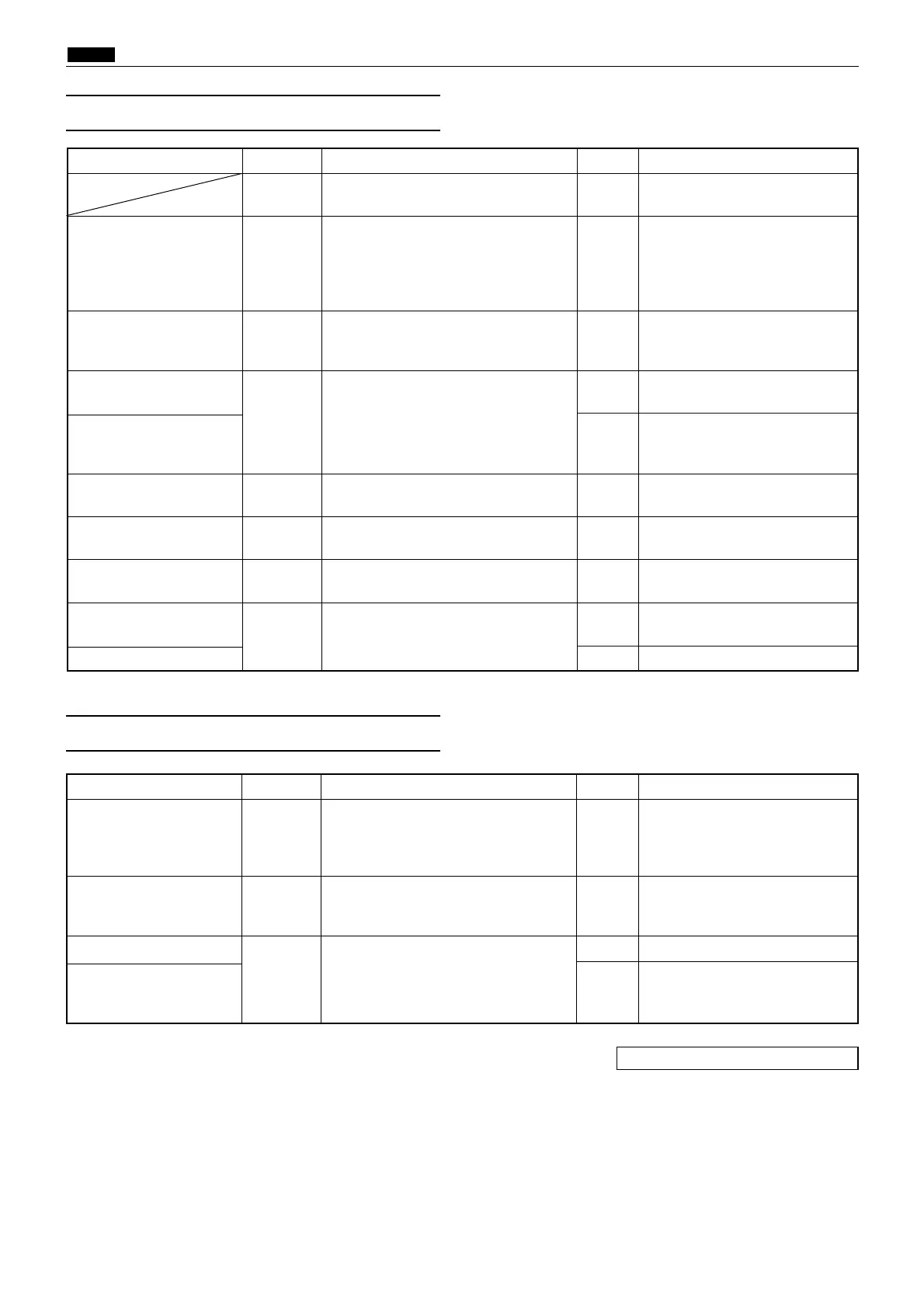

"PLATE EJECTION ERROR" is displayed

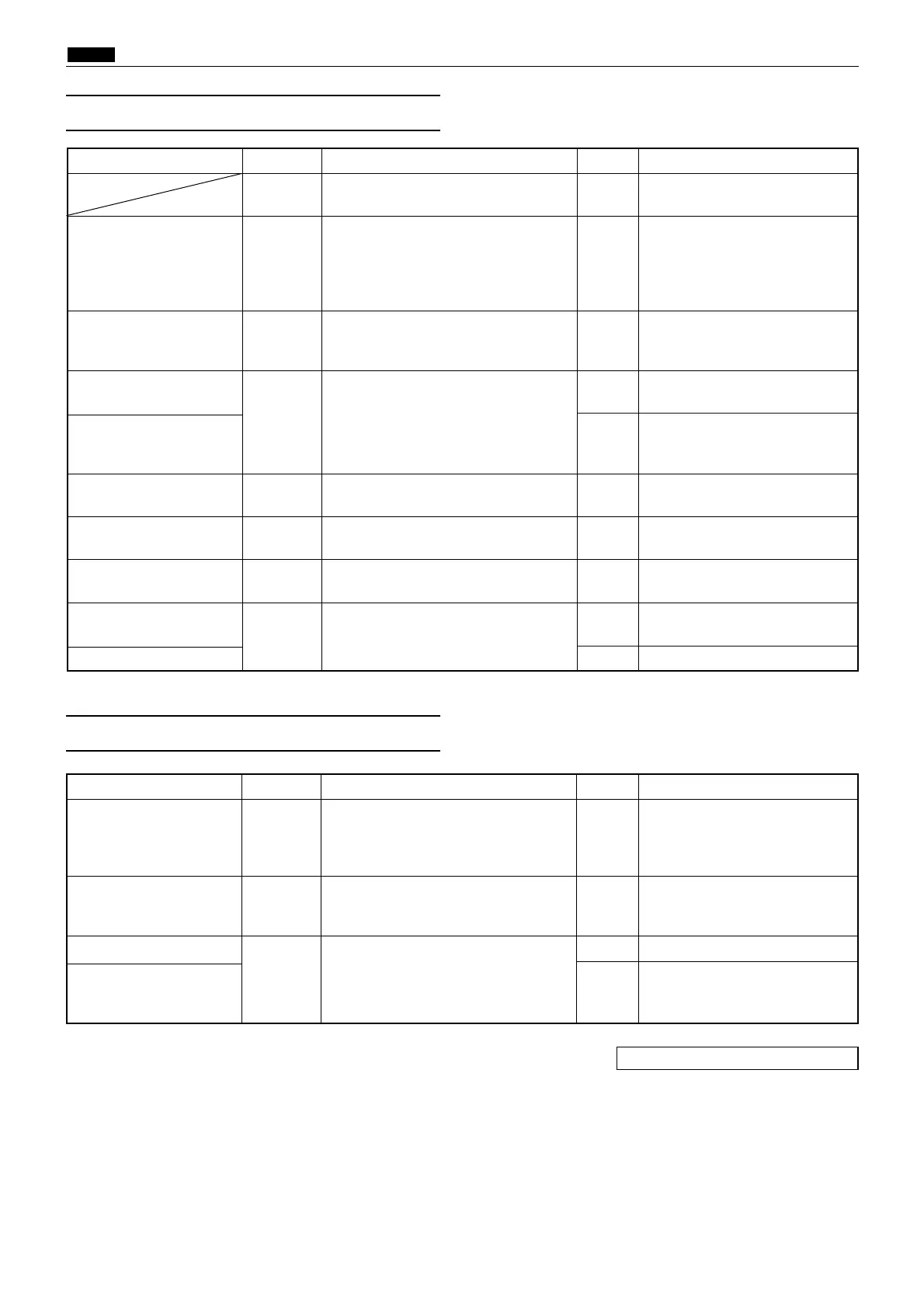

(18) Malfunction of Roll-up Motor

Cause/Defective section Procedures Item to be checked Result Countermeasure

1 YES Proceed to procedure 5.

Foreign material or dirt on 2 YES Remove any foreign matter and

sensors. clean.

Master ejection sensor 3 YES Finish.

photo-receiving

Master ejection sensor 4 YES Finish.

photo-emitting PCB

Main PCB unit NO Check bundled wire and

connectors and replace main

PCB unit.

Roll-up motor

5 NO

Refer to “(18) Malfunction of roll-up

motor”.

Master clump dirty.

6 YES Clean master clump section.

Master ejection box 7 YES Replace any damaged stripper

finger or springs.

Drum master ejection

8 NO Adjust the drum master ejection

stop position stop position.

C mode YES Check and adjust C mode.

Has “PLATE EJECTION ERROR”

actually occurred?

Are there any foreign matter or dirt

between the master ejection sensor

photo-receiving and the master ejec-

tion sensor photo-emitting PCB?

Is trouble cleared by replacing the

master ejection sensor photo-receiv-

ing ?

Is trouble cleared by replacing the

master ejection sensor photo-emitting

PCB?

Does roll-up motor rotate normally?

Is the master clump section dirty with

ink or oil?

Is stripper finger or springs damaged?

Is the drum master ejection stop posi-

tion within reference value?

Cause/Defective section Procedures Item to be checked Result Countermeasure

Roll-up motor

1 YES Replace roll-up motor .

Regulated power supply 2 NO Replace regulated power supply.

Drive PCB unit 3 YES Finish.

Main PCB unit NO Check bundled wire and

connectors and replace main

PCB unit.

Does voltage between drive PCB unit

CN9-24 (+) and -25 (GND) show 24V

when roll-up motor is operated with

HELP mode (H-02)*?

Does voltage between regulated

power supply +S (+24) and -S (GND)

show 24V?

Is trouble cleared by replacing drive

PCB unit?

HELP mode H-02 \ see p.221

*

Loading...

Loading...