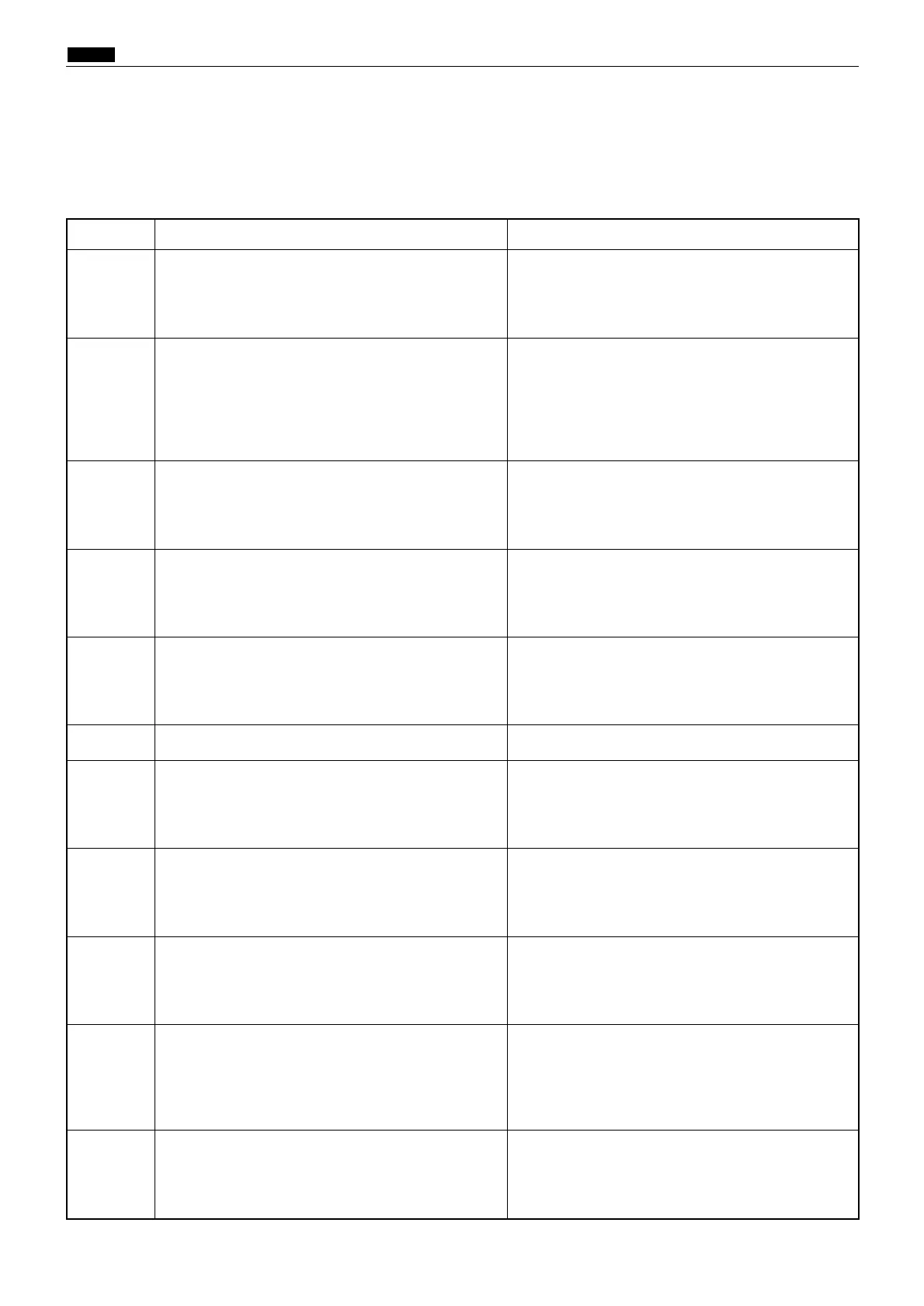

Code display

Cause Detectiontiming

E001

2The main motor is defective.

2The main motor PCB unit is defective.

2The main PCB unit is defective.

2The main motor encoder sensor is defective.

2The regulated power supply is defective.

While the drum rotation signal is lit,the encorder sensor

cannnot detect the edge for 1 second.

E002

2The elevator motor is defective.

2The elevator top limit sensor is defective.

2The elevator bottom limit SW is defective.

2The drive PCB unit is defective.

2The main PCB unit is defective.

2The elevator operation is defective.

2The regulated power supply is defective.

The elevator dose not reach the top limit for 30 seconds after

the elevator up signal is lit.

The elevator dose not reach the bottom limit for 30 seconds

after the elevator down signal is lit.

E005

2The ink roller up/down motor is defective.

2The regulated power supply is defective.

2The drive PCB unit is defective.

2The main PCB unit is defective.

2The ink roller up/down sensor is defective.

While the ink roller up/down motor driving signal is lit,

the ink roller up/down sensor cannnot detect the edge

for 15 seconds.

E006

2The pressure motor is defective.

2The regulated power supply is defective.

2The drive PCB unit is defective.

2The main PCB unit is defective.

2The pressure encoder sensor is defective.

While the pressure motor driving signal is lit,the pressure

encoder sensor cannnot detect the edge for 3 seconds.

E008

2The I/F PCB unit is defective.

2The on-line csble is defective.

2The I/F PCB B unit is defective.

2The P-memory PCB unit is defective.

2The main PCB unit is defective.

During on-line master-making,communication error occurs

between P-memory PCB unit and I/F PCB B unit.

During on-line master-making,communication error occurs

between main PCB unit and I/F PCB unit.

E011

2The thermal head up/down motor is defective.

2The regulated power supply is defective.

2The drive PCB unit is defective.

2The thermal head position sensor is defective.

2The main PCB unit is defective.

While the thermal head up/down motor driving signal is lit,

the thermal head position sensor cannnot detect the edge

for 4 seconds.

E009

2The thermal head is defective.

2The regulated power supply is defective.

At start of master-making, thermal head drive voltage

dose not reach reguration value.

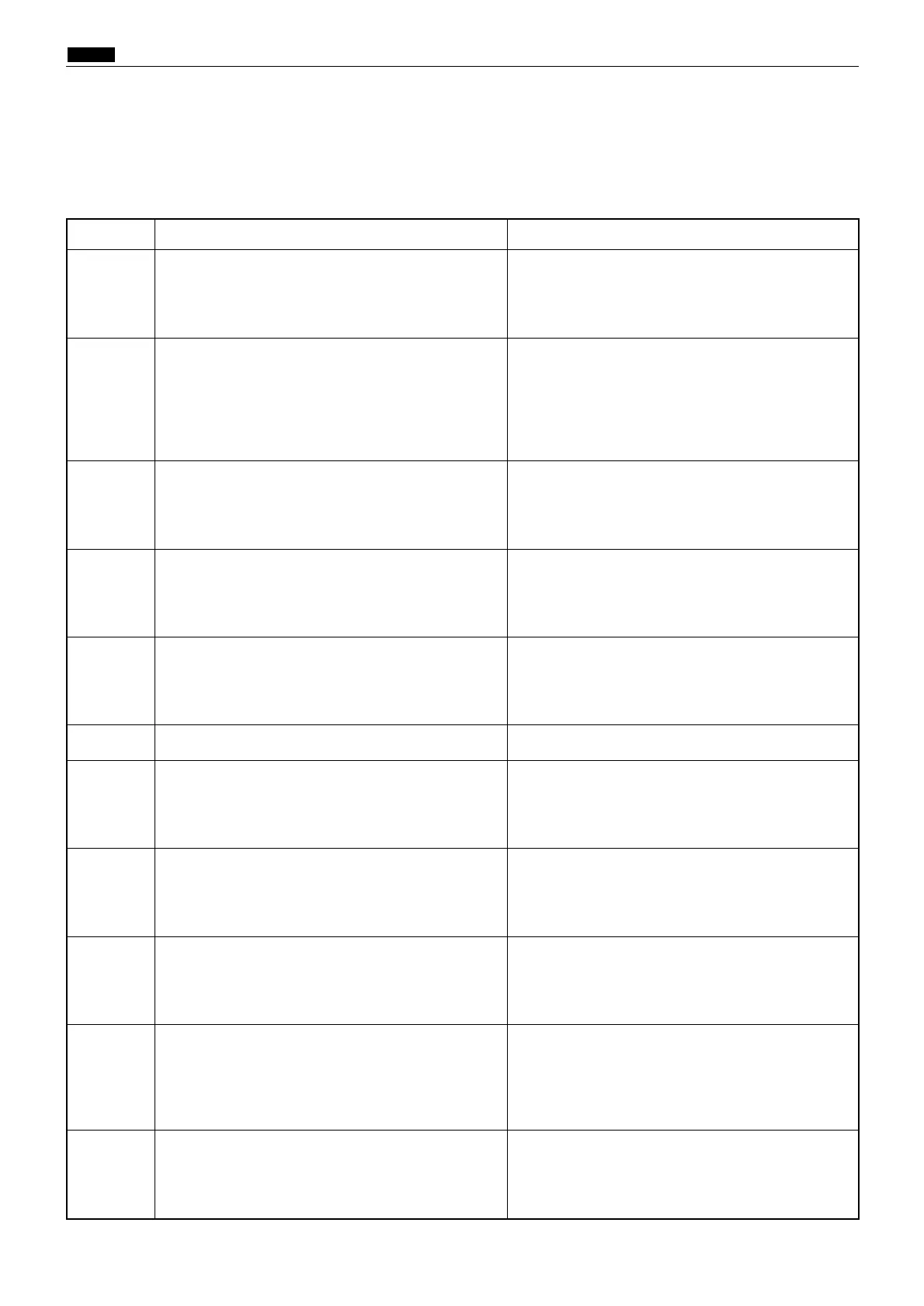

E013

2The scanner stepping motor is defective.

2The regulated power supply is defective.

2The main PCB unit is defective.

2The scanner home position sensor is defective.

2The drive PCB unit is defective.

At master-making, while the scanner stepping motor driving

signal is lit

,the scanner home position sensor cannnot detect

the edge for 17 seconds.

E014

2The regulated power supply is defective.

2The G-roller motor is defective.

2The G-roller sensor is defective.

2The main PCB unit is defective.

2The drive PCB unit is defective.

While the G-roller motor driving signal is lit,the G-roller

sensor cannnot detect the edge for 2 seconds.

E015

2The regulated power supply is defective.

2The main PCB unit is defective.

2The drive PCB unit is defective.

2The top/bottom motor is defective.

2The top/bottom encoder sensor is defective.

2The top/bottom center sensor is defective.

While the top/bottom motor driving signal is lit,the top/bottom

encoder sensor cannnot detect the edge for 3 seconds.

E016

2The regulated power supply is defective.

2The main PCB unit is defective.

2The drive PCB unit is defective.

2The drum limit/center sensor is defective.

2The drum shift motor is defective.

While the drum shift motor driving signal is lit,the sensor

cannnot detect the edge for 12 seconds.

Loading...

Loading...