90

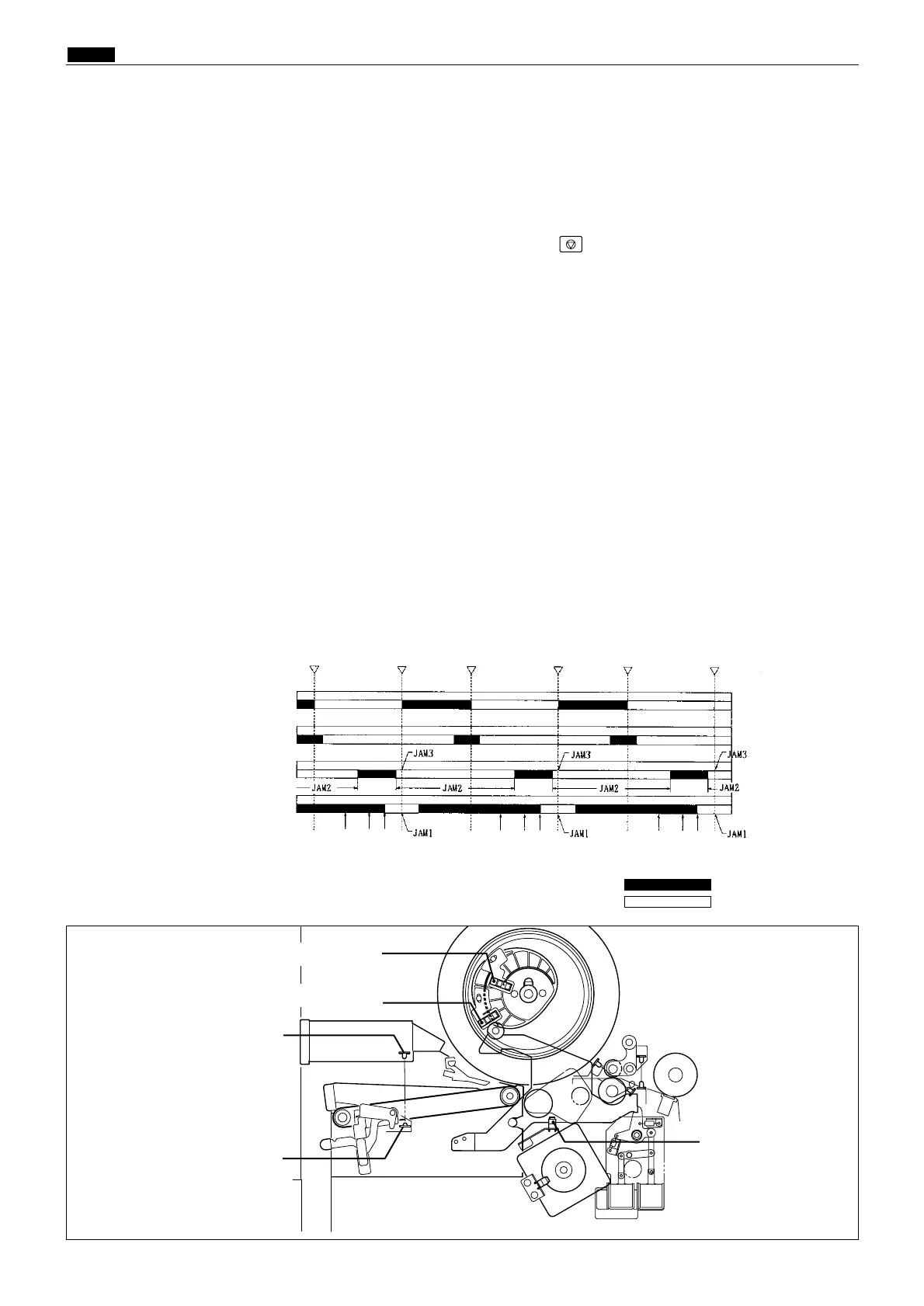

n Paper Ejection Section

chap.2

2Paper jamming on the ejection side

JAM1: The bottom end of the paper is not ejected.

When the JAM sensor (light-emitting and light-receiving) is interrupted at the timing of JAM detection

position edge (photopassing \ photointerrupting) of the drum stop / JAM detection position sensor

PS5.

JAM2: The tip end of the paper is not ejected.

When the JAM sensor is not interrupted at all while the P-roller sensor is in the state of photopassing

(pressed ON).

JAM (stop): When the JAM sensor is interrupted as the top blow fan unit is open when the machine stops.

The display is cleared when the sensor is in the state of photopassing.

2Paper jamming on the feeder side

JAM3:

The paper does not pass the signal sensor though the paper is fed. The P-roller sensor is not in the state

of photopassing when the drum rotates twice after the paper feed is ordered ON.

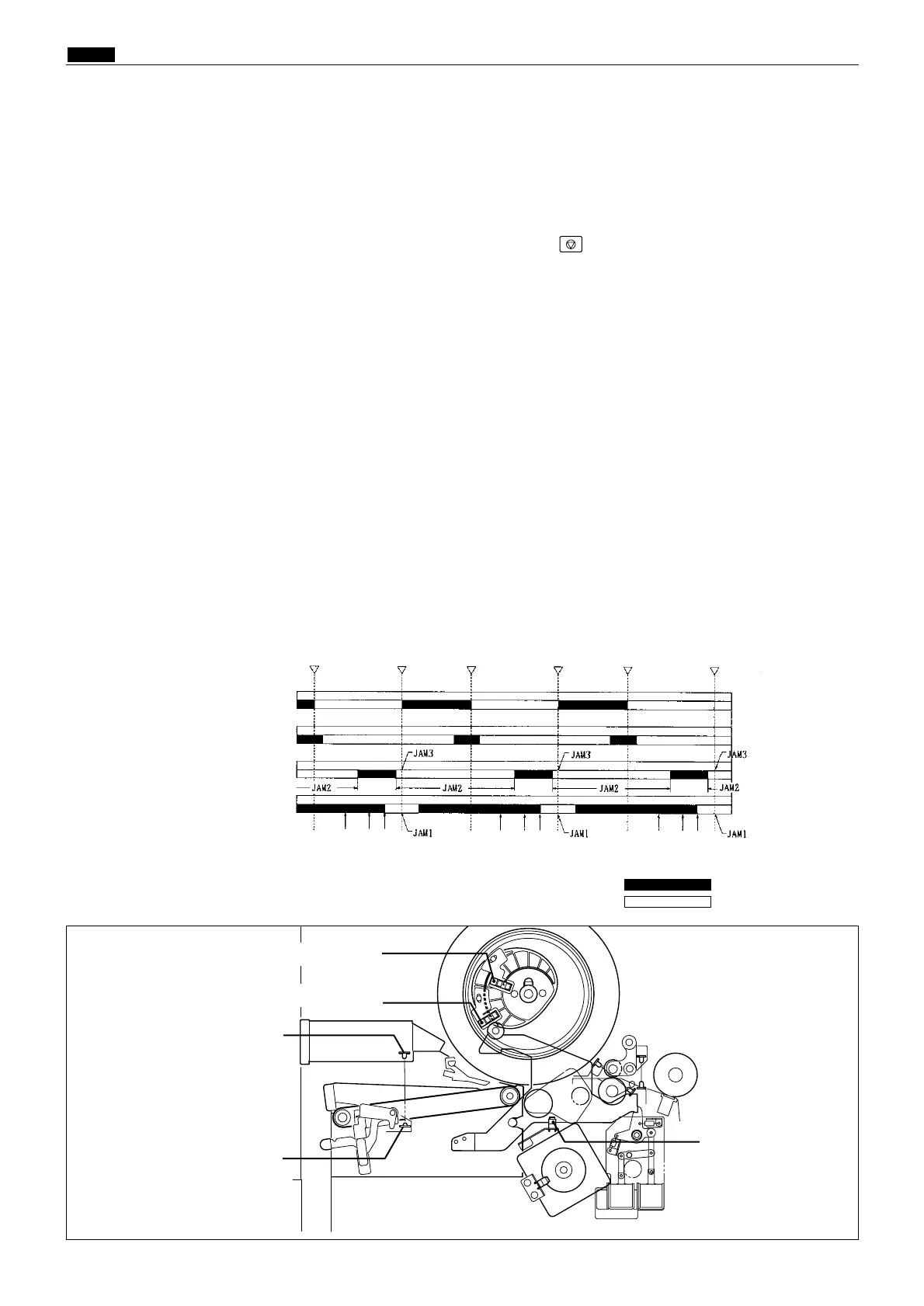

1. Paper Jam Detection Timing

Description

Paper jamming is divided into two types: "PAPER JAM ON THE EJECTION SIDE" and "PAPER JAM ON THE

FEEDER SIDE". Paper jamming is detected under the following conditions. When paper jamming is detected,

"PAPER JAM" is displayed on the LCD panel, and the machine stops printing operation. The display is

cleared by removing the cause of paper jam and pressing the STOP key or by restarting printing.

Sequence of Operation

440327

Paper ejection JAM

sensor(Photo-emitting)

P-roller sensor

Master set/removal position sensor

Paper ejection JAM

sensor(Photo-receiving)

Drum stop/JAM detection position sensor

Drum stop/JAM detection position sensor

Master set/removal position sensor

P-roller sensor

Paper ejection JAM sensor

Drum stop position sensor

JAM detection

position sensor

Drum stop

Drum stopJAM

A4 B4 A3

A4 LG B4

DP-440 / DP-430

DP-340 / DP-330

Bottom end of paper

Sensor photointerrupted

Sensor photopassing

JAM

A4 B4 A3

A4 LG B4

A4 B4 A3

A4 LG B4

Loading...

Loading...