62

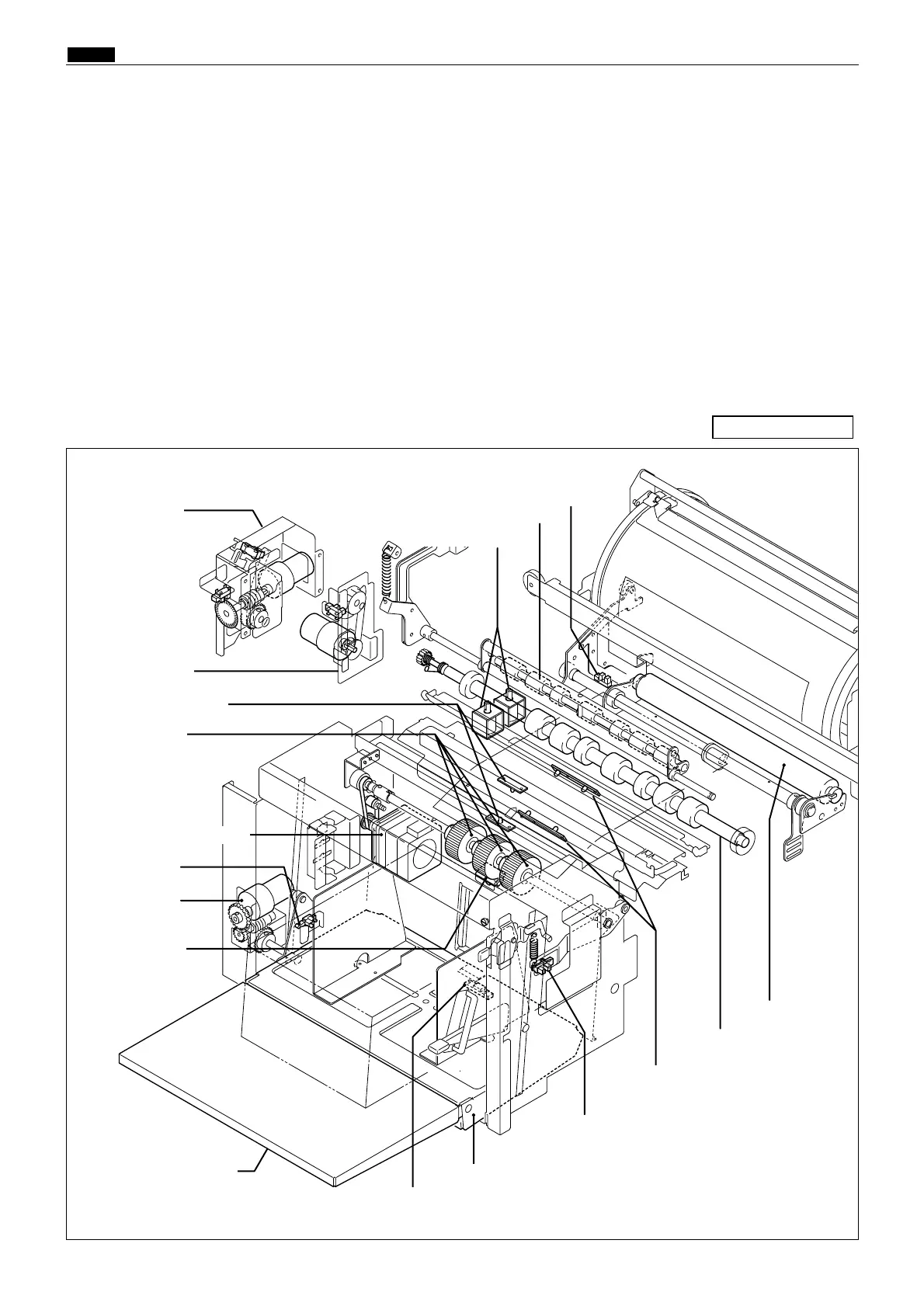

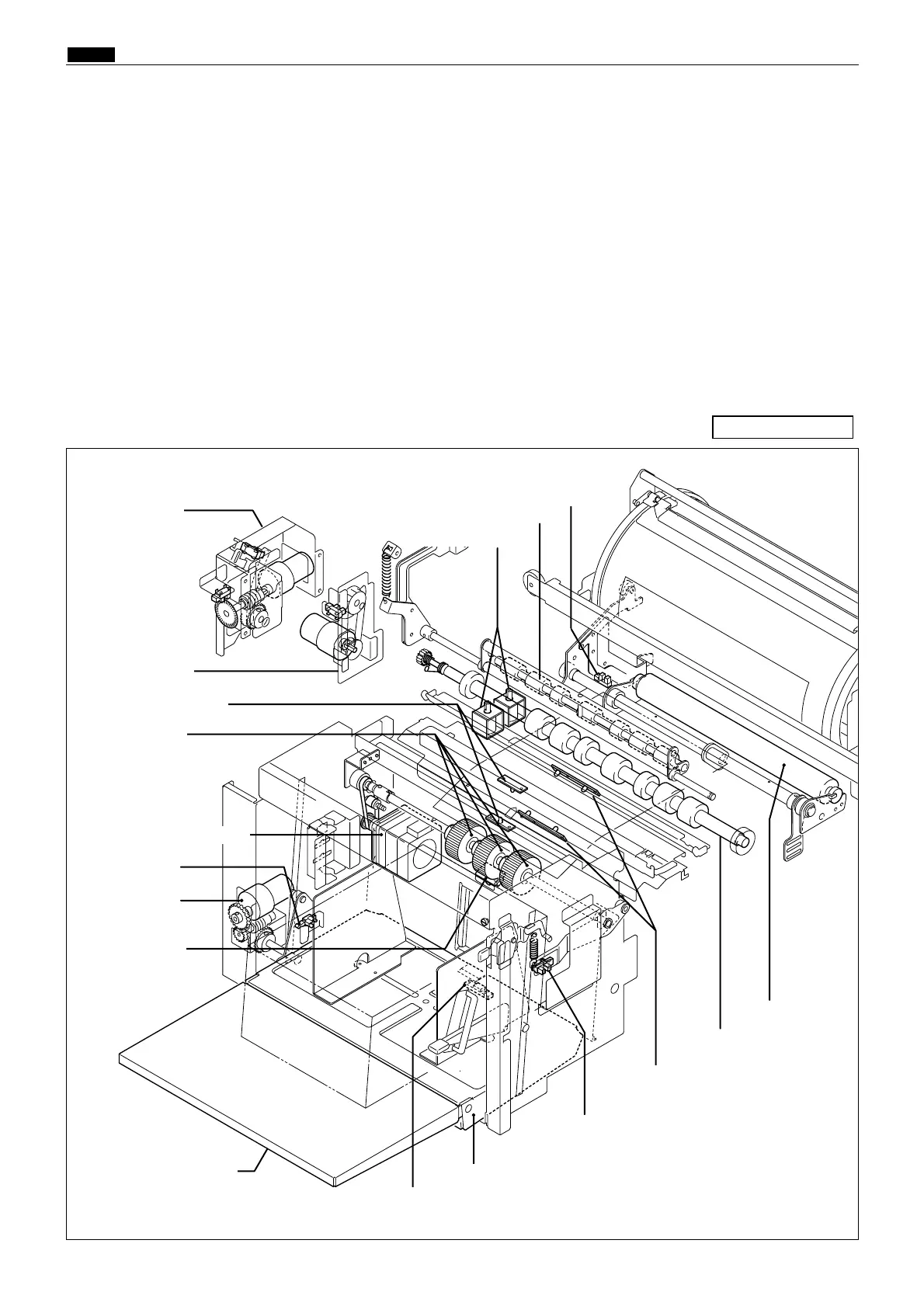

c Paper Feed Section

chap.2

1. Description

Feeding of the paper is performed by the paper separator (employing the center separation method) and paper

feed roller (there is no corner finger). Elevation of the feed tray is powered by the elevator motor.The paper

lead edge sensor is equipped at the rear of the paper feed roller. When the paper does not reach the paper lead

edge sensor or the signal sensor during the preliminary feeding, “PAPER JAM ON THE LEFT SIDE” appears.

Paper fed by the paper separator and paper feed roller is fed further by the timing roller and guide roller to

the point where its leading edge is sandwiched between the drum and the press roller. Then the pression of

the timing roller and guide roller is released (by moving the guide roller upward several mm), so that the

paper is fed through at a speed equal to the circumferential speed of the drum and press roller. The press

roller sensor senses the paper feed condition; if a feed error occurs, the message “PAPER JAM ON THE

FEEDER SIDE” is

displayed.

For details, see “1.Paper Jam Detection Timing” in chapter 2 (n Paper ejection section).

\See page 90

cPaper Feed Section

(Signal solenoid)

440301

Paper separator

Paper feed roller

Elevator motor

Feed traySupplemental paper tray

Timing roller

Press roller

Guide roller

P-roller sensor

LPU

(Long Paper Unit)

Paper detection sensor

Elevator top limit sensor

Elevator bottom

limit switch

Paper feed stepping motor

Printing position

adjusting unit

Paper lead edge sensor

Double feed detection sensor

Loading...

Loading...