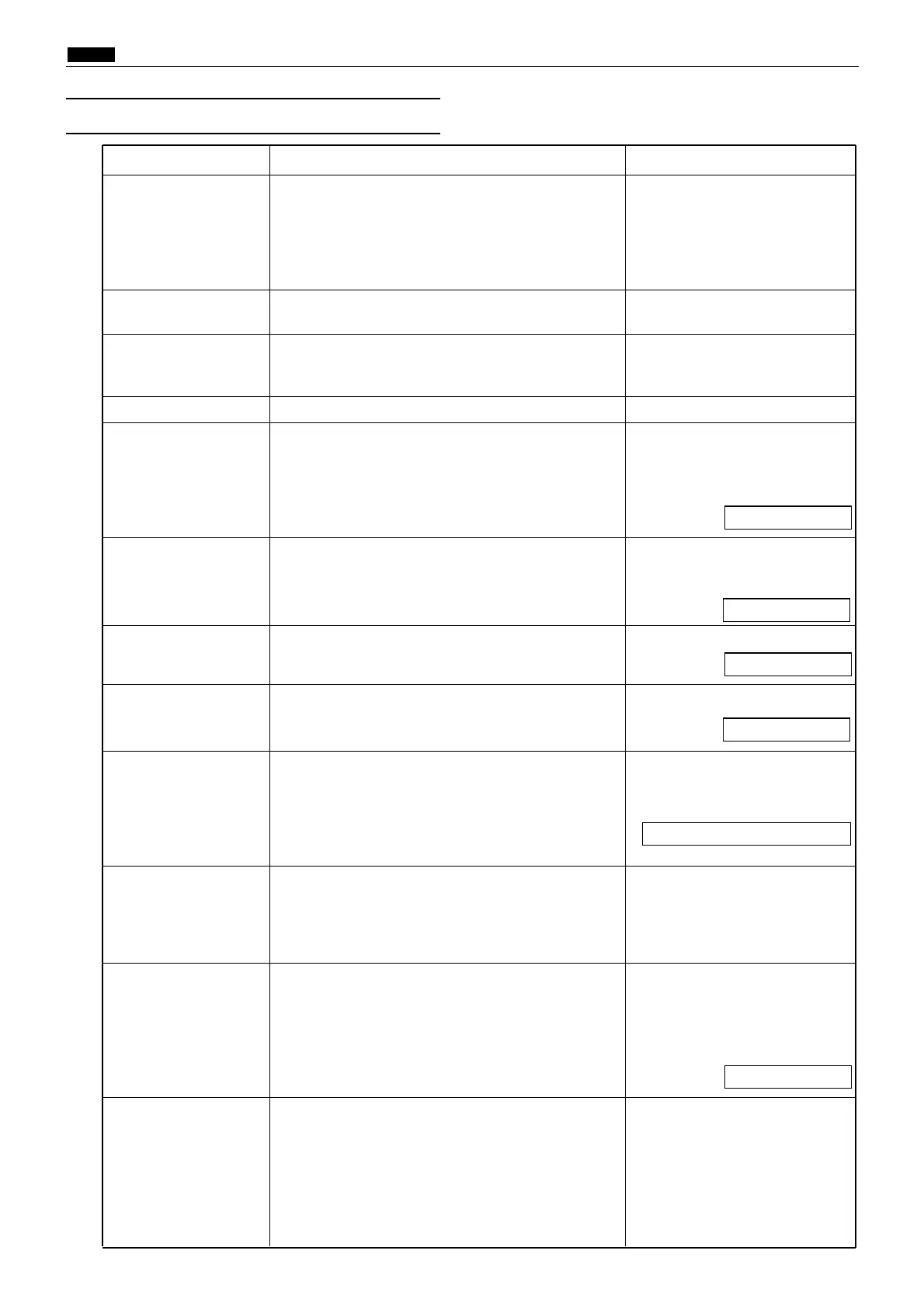

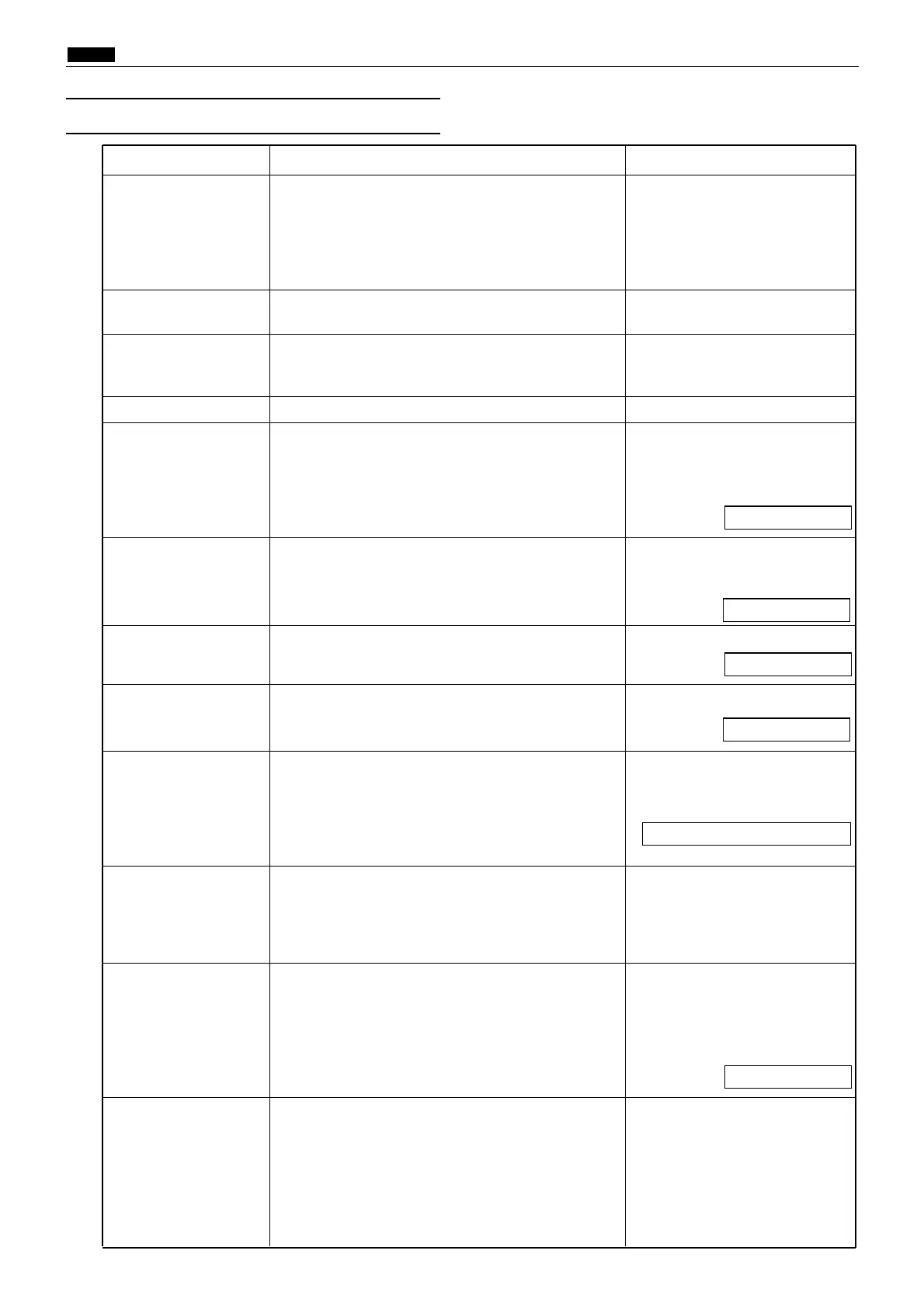

Causes Symptoms Countermeasure

Printing paper not suit-

able

• If paper is too thick, it won’t be likely fed. If too thin, dou-

ble sheets may be fed.

• Paper not clearly cut: 2 sheets still adhere to each

other.

• Much paper scraps may deteriorate the paper feed

roller and separator performance.

Explain causes to user. Have user

change to the paper conforming to

specifications.

Dirt / foreign matter in

transfer path

• Paper gets stuck in transfer path, causing creasing and

tearing.

Remove any dirt or foreign matter.

Incorrect paper feed path

pressure

• If pressure on paper is insufficient, paper will not be fed.

• If pressure on paper is excessive, double sheets will be

fed.

Explain to users how to select cor-

rect pressure for paper.

Worn paper feed roller • Paper may not be fed. Replace paper feed roller.

Paper separator unit gap • If gap is too large, separator unit will rattle in direction of

paper transfer path, causing double sheets to be fed.

• If gap is too small, paper separator unit cannot follow

angle change due to paper feed shaft up-down move-

ment, which may cause double-sheet or slanted feed,

and creasing.

Perform paper separator unit gap

adjustment.

Paper separator unit • Wear, or adhesion of paper scraps causes deterioration

in separating performance, resulting in double-sheet

feed.

Clean separating surfaces. If any

trouble exists, replace. Perform sep-

arator unit gap adjustment on new

unit.

Separation pressure • If pressure is very low, no paper will be fed. Perform separation pressure adjust-

ment.

Elevator top position limit • Paper slant is large, causing creases.

• During printing, paper feed errors often occur immedi-

ately before or after paper tray rises.

Perform elevator top limit sensor

adjustment.

Paper feed amount • If amount is too short, paper slant cannot be corrected,

printing position may not be uniform, or paper may not

be fed.

• If amount is too long, loop becomes too large, causing

paper to buckle up between paper feed roller and timing

roller, resulting in feed error.

Perform paper feed amount adjust-

ment.

Paper feed clutch • Clutch slippage will reduce paper feed amount.

• If clutch does not disengage properly, the paper feed

segment gear will not return correctly, leading to

reduced feed amount.

(See “Paper feed amount” above.)

Replace paper feed cluch.

Guide roller pressure &

timing

• If Guide roller pressure is insufficient, paper will not be

gripped properly, and timing roller will not assure con-

stant feed amount. As a result, printing position will not

be uniform. In the worst case, no paper will reach drum.

• If there is a gap between Guide roller and the timing

roller, paper slant cannot be corrected.

Perform escape amount adjustment

and escape timing adjustment.

Timing roller • If the timing roller clutch slips, feed amount will not be

constant. As a result, printing position will not be uni-

form. In the worst case, no paper will reach drum.

• If the timing roller clutch does not disengage properly,

the paper feed segment gear will not return correctly,

leading to reduced and unstable feed amount. As a

result, printing position will not be uniform. In the worst

case, no paper will reach drum.

Clean timing roller clutch . Replace

if necessary.

Loading...

Loading...