CHAPTER 8

176

Troubleshooting

4/29/10 Rev G

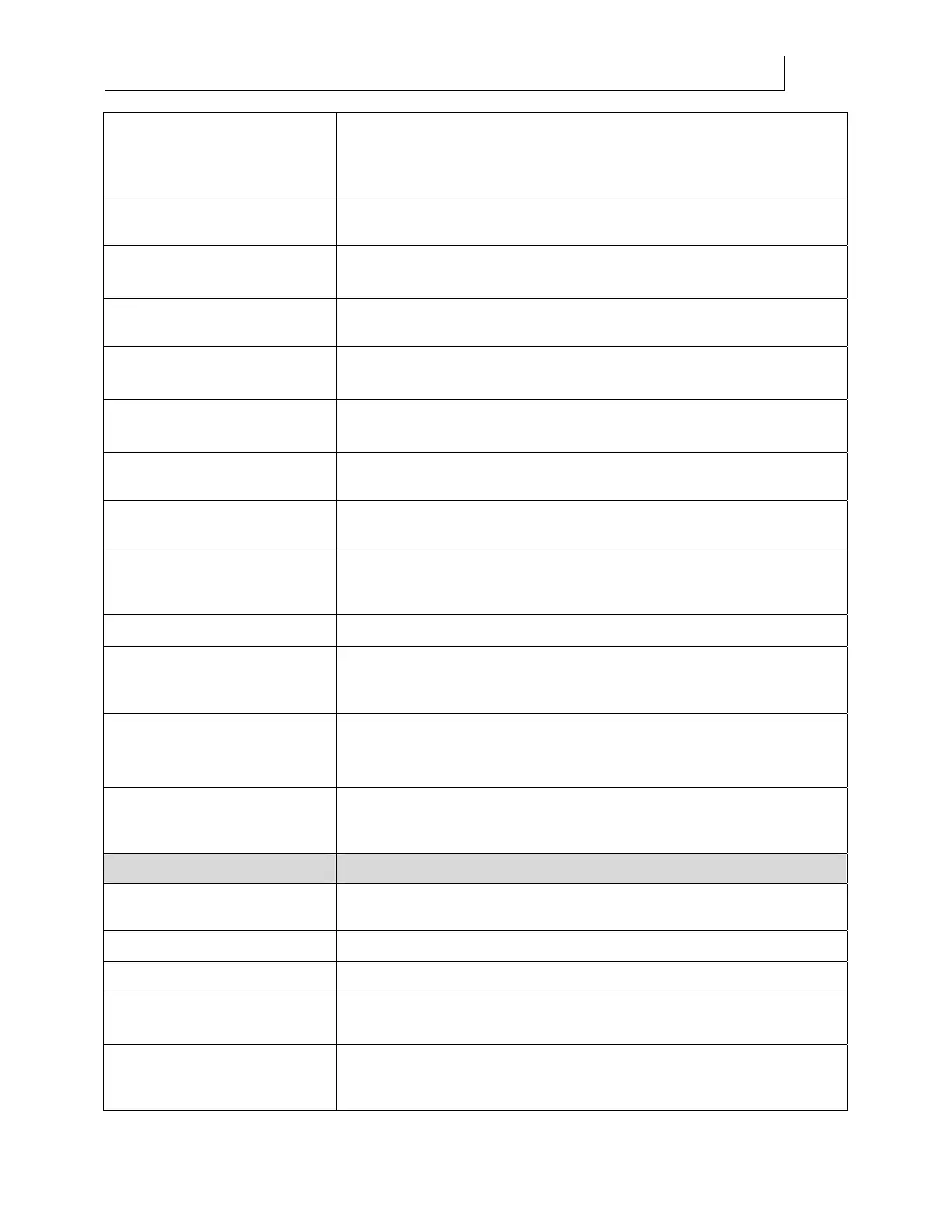

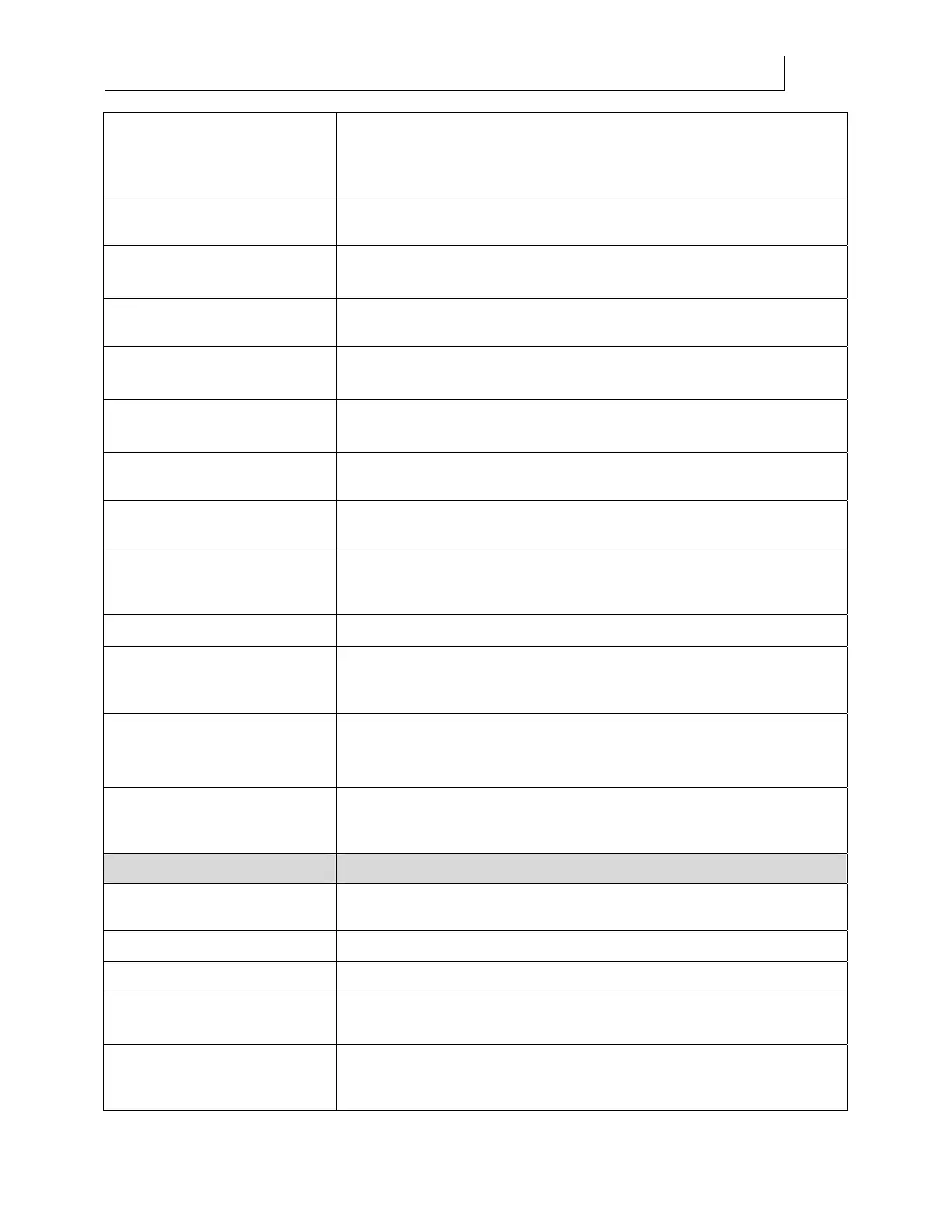

Cannot fill ink

Ink filling can not occur due to a problem with the system which could

include failure to set ink vacuum pressure, waste ink tray not installed,

an empty ink line or a problem with another ink component. Check

Message Log and fix condition.

Lower Shelf

Displays during ink maintenance procedures. Lower the maintenance

shelf to gain access to the heads.

Remove Head Access

Door

Displayed during ink maintenance procedures. Remove the head access

door to locate the ink purge valves.

Replace Head Access Door

Displayed during ink maintenance procedures. Replace the head access

door after purging ink valves.

Open “INK COLOR” Purge

Valve 1

Displays during ink purge procedure. Use the 2mm Allen wrench to

open the indicated purge valve.

Open both “INK COLOR”

Purge Valves

Displays during the clear ink line procedure. Use the 2 mm Allen

wrench to open both purge valves for the same color printheads.

Close all purge valves

Displays during ink purge procedure. Use the 2mm Allen wrench to

close the purge valves for the ink color(s) that were purged.

Clean the Purge Block

Displays during the clear ink line procedure. Wipe the bottom of the

purge block with a dry swab to absorb any ink drips.

Check Ink Waste Tray

Displayed during ink maintenance procedures. Check the waste ink

tray and empty if necessary. Ensure tray surfaces are clean and dry and

replace the all purpose wipe(s).

Remove All Ink Pouches

Displayed during the Clear Ink Line procedure.

Updating Front Panel

Firmware

Displays at start-up when the front panel board is being updated.

Printer power must remain on or errors will occur. Wait until update is

complete.

Loading “component” F/W

or FPGA.

Leave power switch on.

Displays when individual component firmware is in the process of

being updated. A progress bar displays. Printer power must remain on

or errors will occur. Wait until update is complete.

Checking “component”

F/W or FPGA

Displays during the check phase after a component is updated. A

progress bar displays. Printer power must remain on or errors will

occur. Wait until update is complete.

Common Printer Messages Description

Motor Power Cycled!

The X-axis, Y-axis, Z-axis, and roll-to-roll motors are

turned on after an Emergency Stop.

Calibration is set!

Displays when calibration values are saved.

Lamp Delay is ON/OFF

Displays to indicate the status of Lamp Delay mode.

Lamp Spec mode is

NORMAL/HIGH

Displays to indicate the status of Lamp Spec mode. NORMAL is the

default; HIGH operates the lamps at a higher temperature.

Large Field is ON/OFF

Displays to indicate the status of Large Field mode. Large Field ON

improves the appearance of large areas of solid color, especially light

blue or green. Large Field is OFF by default.

Loading...

Loading...