CHAPTER 6

81

Routine Printer Maintenance

4/29/10 Rev G

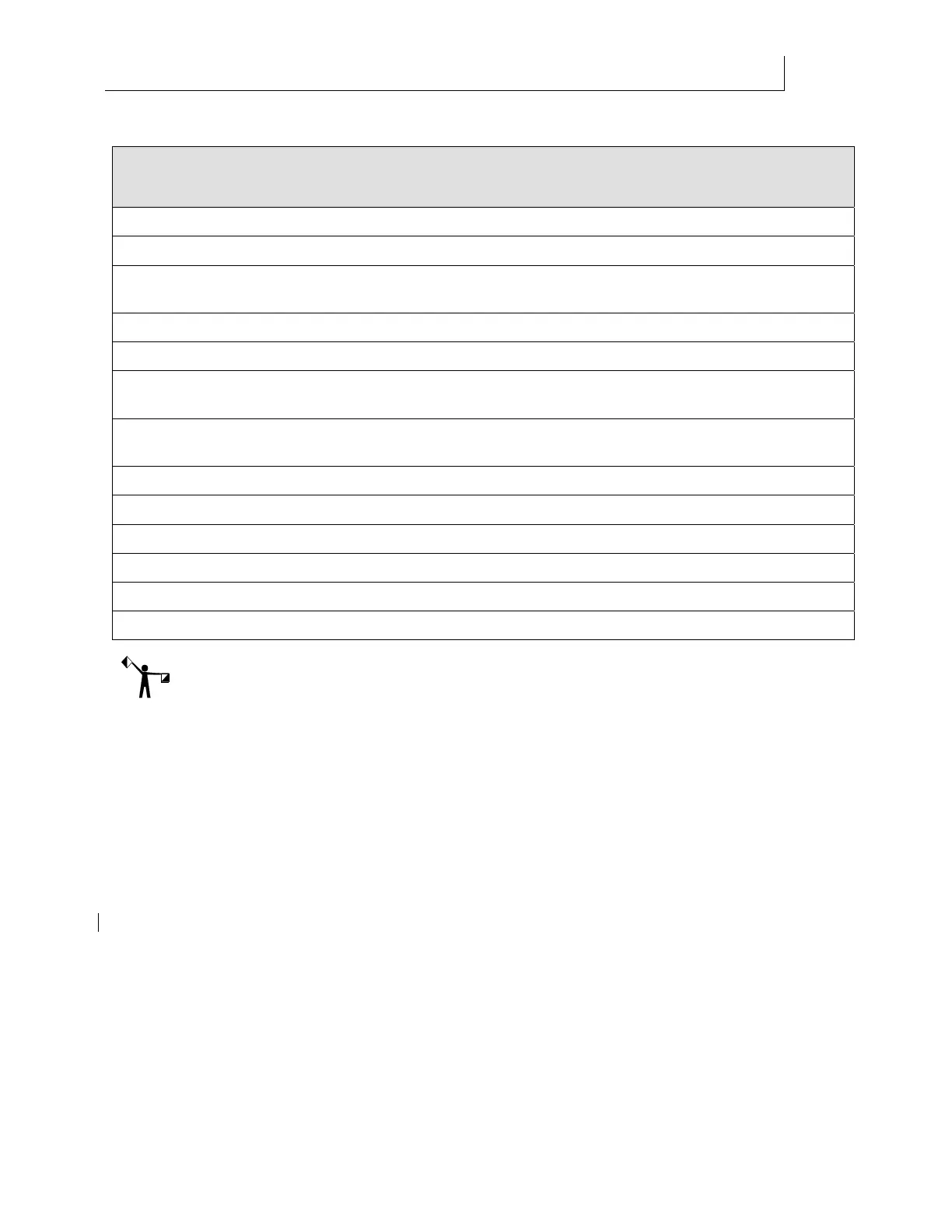

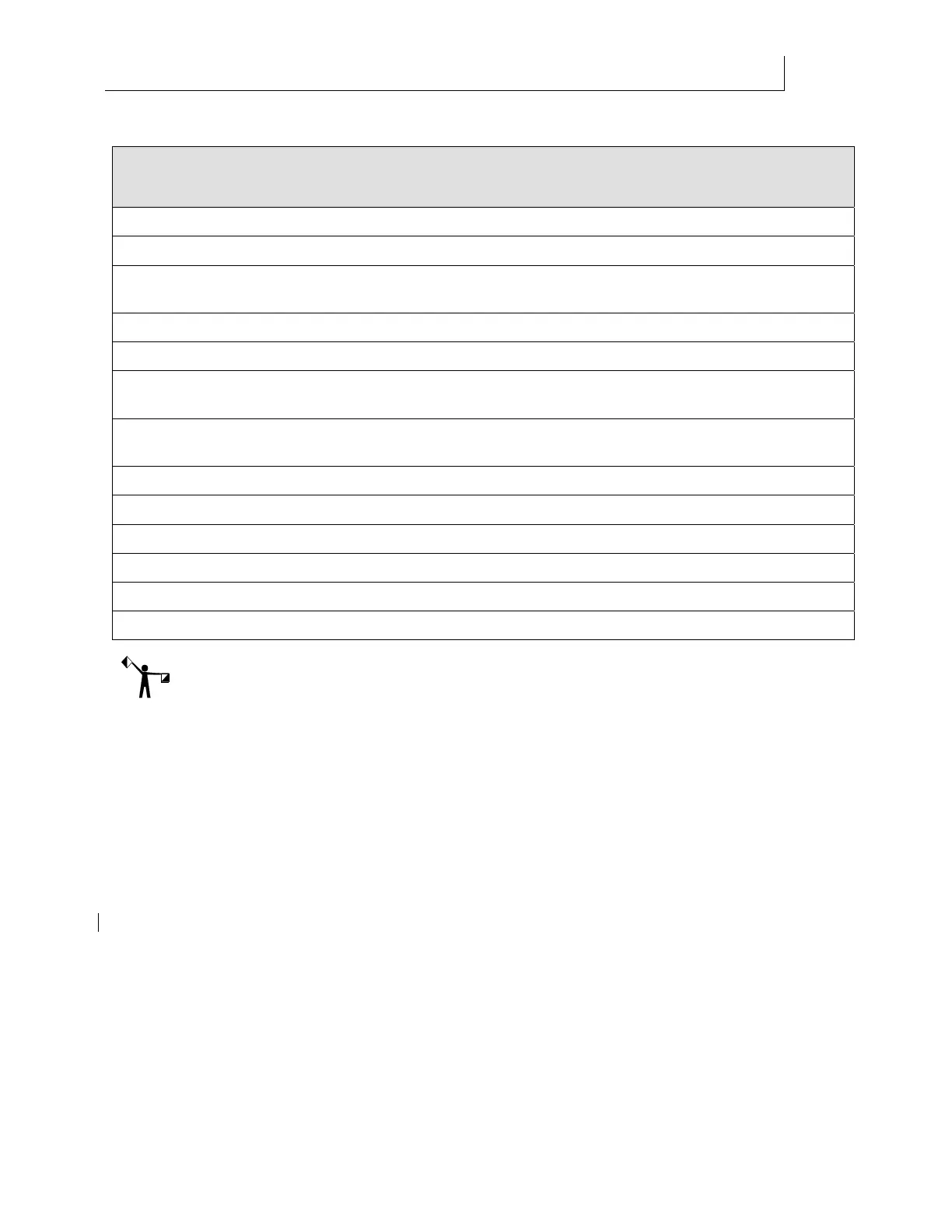

Maintenance procedures that must be performed by an authorized

Gerber technician every 12 months

Replace the two vacuum table motors (at 1000 hours instead of 12 months).

X-axis - clean and lubricate the rails, check the steel belts and drive belts.

Y-axis – check and lubricate the rails and bearings, and check the tension and tracking of the steel belt

and drive belt.

Z-axis – clean and lubricate worm gears and rails, and check the coupler screws for the Z motor.

Roll-to-roll – check rubber clutch drive and rollers.

Clean the encoder strips (one Y and two Z- axes) and check alignment.

Run Y-axis encoder test and recalibrate.

Check for ink leaks at all ink connections. Replace ink pouch fittings, purge block set screws, and

vacuum filter. Lubricate ink drawer runners.

Inspect the UV lamps.

Clean and check the operation of all fans.

Check all the electrical/electronic connectors.

Check the operation of the interlock circuit.

Check the operation of the maintenance shelf gas struts

Inspect the sliding UV Shield for correct operation

Note: As with all parts, replace on an as-needed basis in the case of breakage or failure.

Other Customer Activities to optimize output quality

In general these settings are included in the material profile of the RIP software, but a customer can

adjust them as needed.

Media Feed for Roll-to-Roll – 240mm line test

Unidirectional alignments and bidirectional alignment

Large Field Mode

Step Blending mode

X Gantry Adjustment

The Gerber Solara ion should be left powered on for 24/7 in order to maintain ink vacuum

The printer has a sleep mode in which heaters are turned off after two hours of idle time.

Shut down for more than two weeks

If you need to shut down the printer for more than two weeks you must follow the procedure “Shutting

the printer down for more than two weeks” on page 114.

Loading...

Loading...