COMMISSIONING

234 Service Manual Part No.: 4417340 Revision 1

954 SmartServo FlexLine

Level calibration using the top of ball valve

If level dipping is not possible, the 954 SmartServo FlexLine can be

calibrated using the top of a ball valve as reference point.

Make sure the servo auto test downwards is disabled, else the servo gauge will end

up in a SAT failure and will stop measuring level. Refer to section 8.7

Proceed as follows:

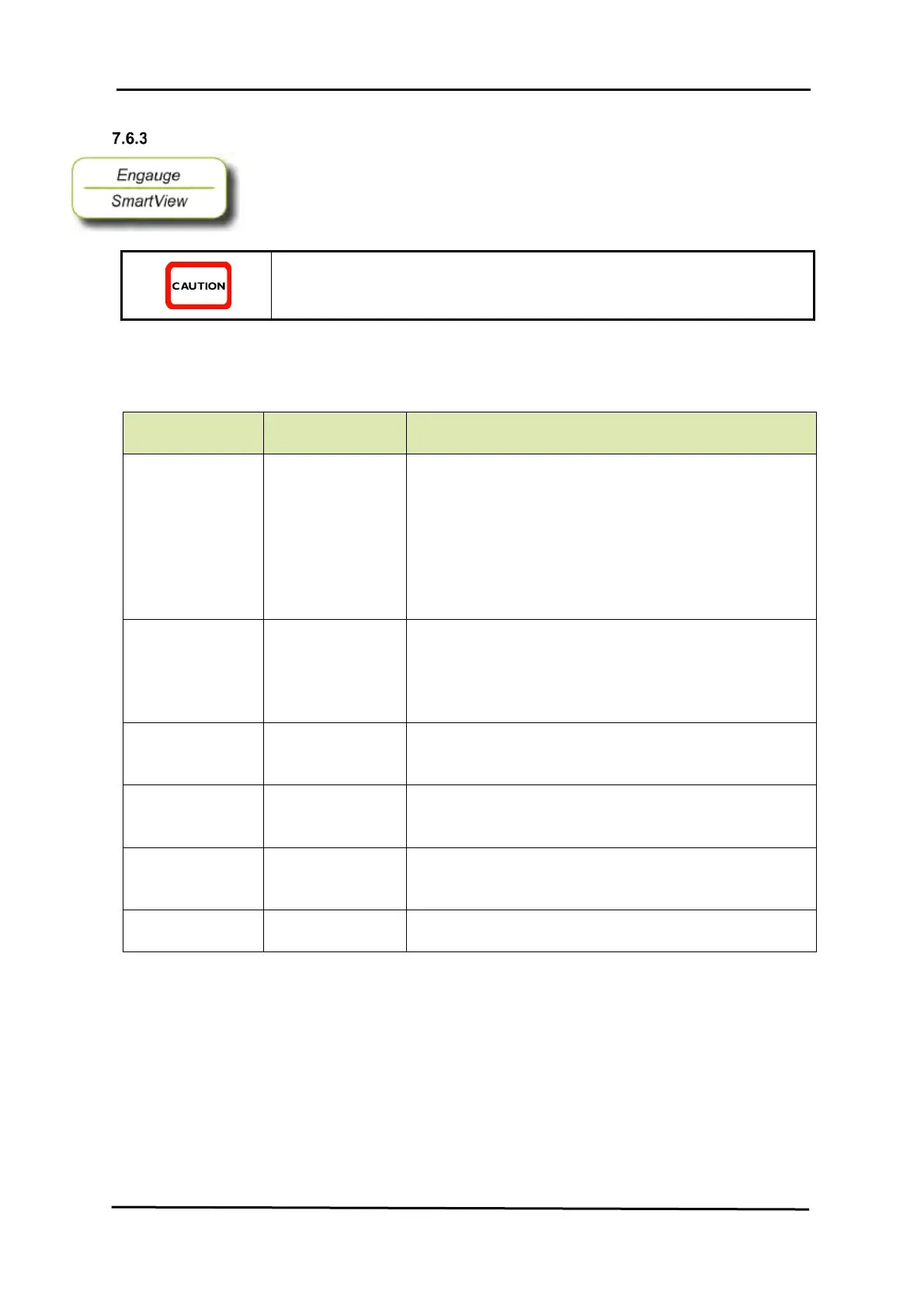

Entity name Entity name

(SmartView)

Description

[Calibrate] [Calibrate]

(Product level)

The displacer will be raised until it stops against the

flange of the level gauge.

Caution

If a 45 mm displacer is used, immediately stop the

Calibrate command as soon as the displacer is above

the ball valve, followed by a freeze command.

Make sure the displacer is positioned above the ball

valve. Close the ball valve.

[Unlock] [Unlock]

(Product level)

Unlock the gauge and wait the displacer reaches the top

of the ball valve.

Calculate the immersion depth of the displacer at the

product interface (for a 90 mm displacer use 3 mm; for a

45 mm displacer use 12 mm).

[Reference level] [Reference level]

(Product level)

Enter the position of the top of the ball valve with respect

to the tank zero adding the immersion depth of the

displacer at the product level.

[Accept reference] [Accept reference]

(Product level)

By giving this command, the level value entered in entity

[Reference level] is accepted as level value and will be

shown on the display after the automatic reset.

[Calibrate] [Calibrate]

(Product level)

The displacer will now raise from the ball valve. Let it

stop against the flange or give a freeze command.

Open the ball valve.

[Unlock]

[Unlock] (Product

level)

Unlock the gauge. The displacer will now move down till

it reaches the level

For verification of the level calibration, refer to section 8.8.2

Loading...

Loading...