TROUBLE SHOOTING

284 Service Manual Part No.: 4417340 Revision 1

954 SmartServo FlexLine

11 TROUBLE SHOOTING

11.1 Problems with displacer movement

If the displacer is not running freely, for instance stuck against a stilling

well, it can be controlled manually.

Note: Be aware that measuring wire is unrolled from the measuring

drum. When the measuring wire is not kept at tension, the result will be

an uncontrolled wire movement which results in the worst case in the

loss of the measuring wire.

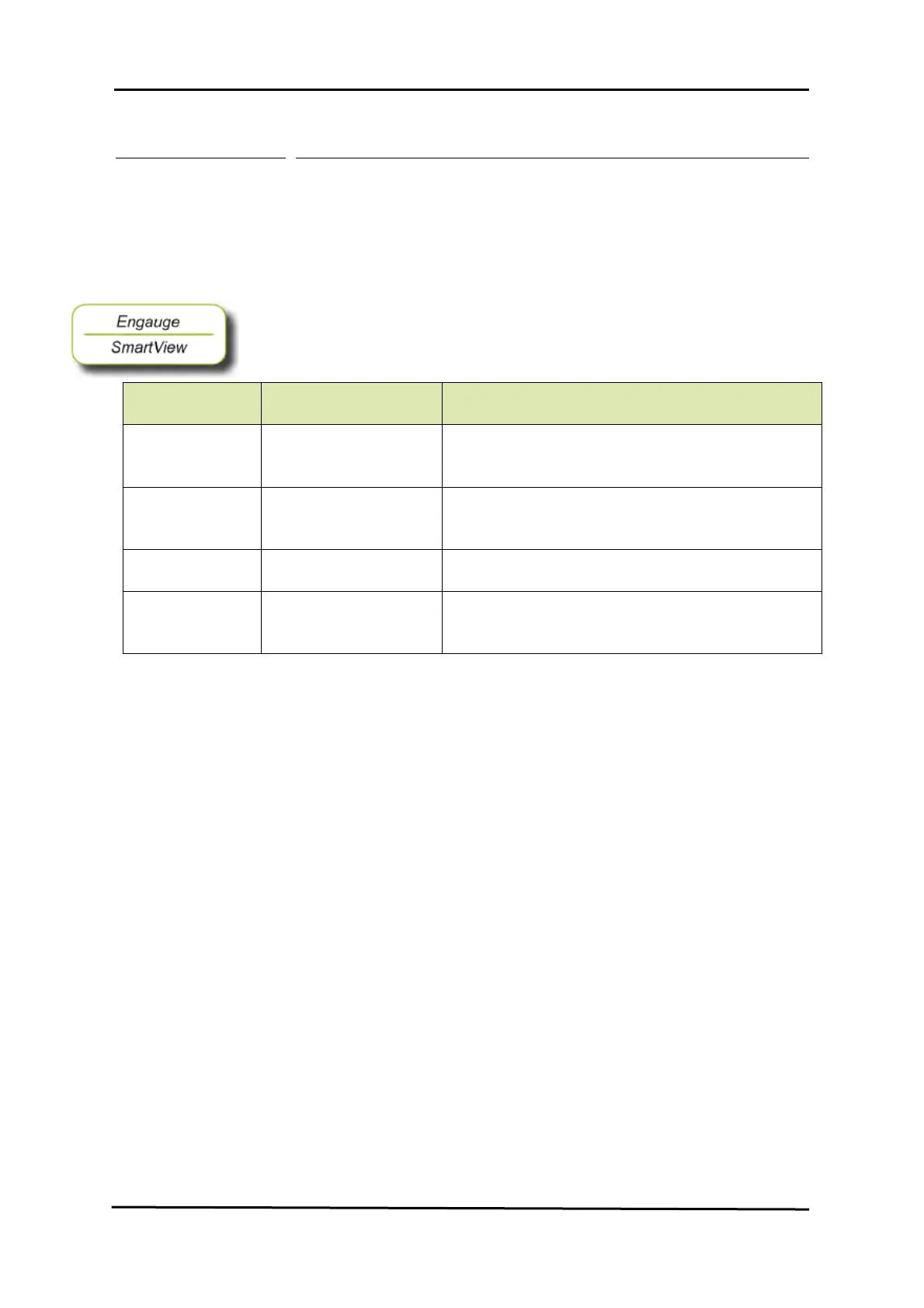

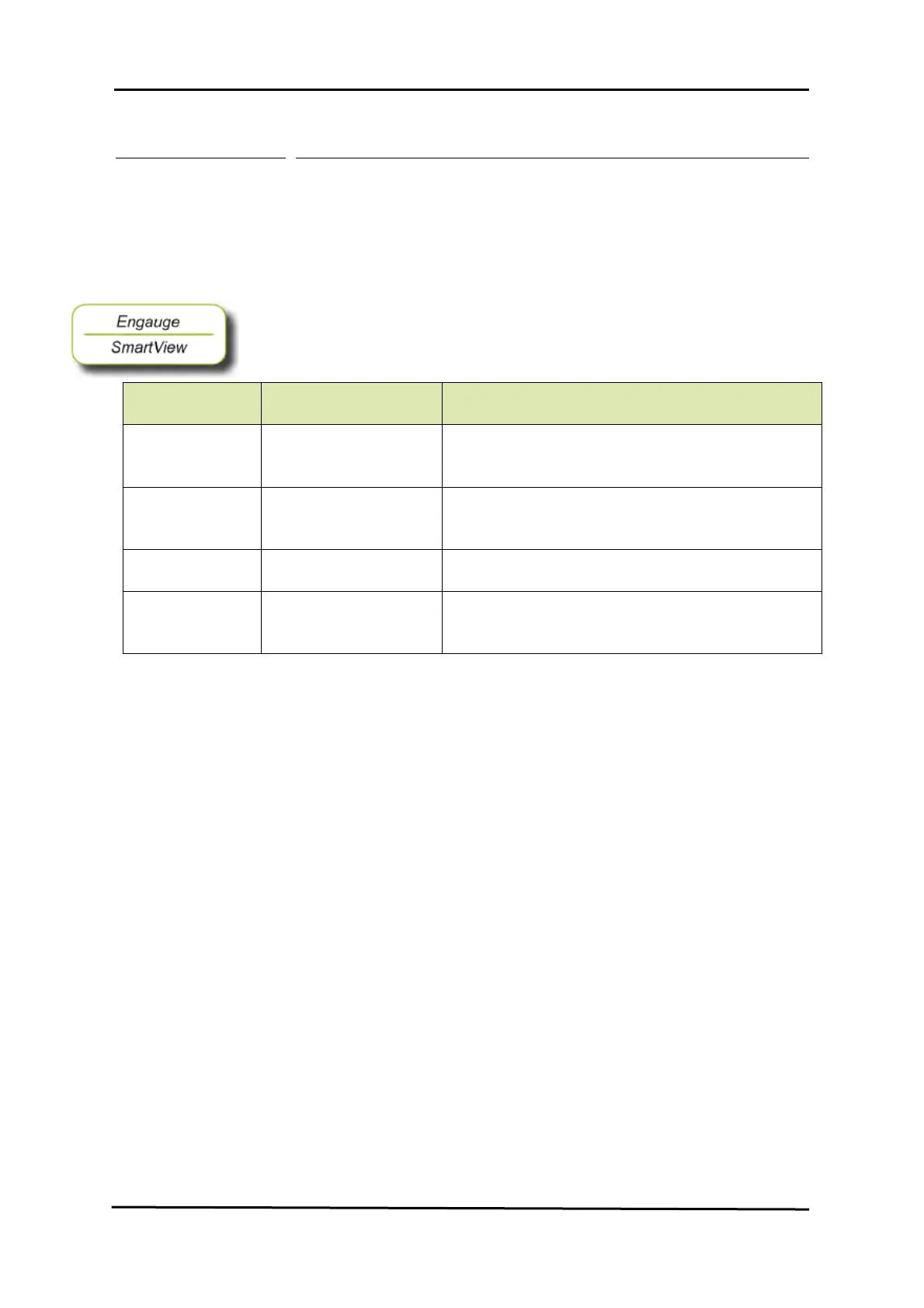

Entity name Entity name

(SmartView)

Description

[Set to

maintenance

mode]

[Maintenance mode]

(Product level)

Go into maintenance mode.

[Go down] [Go down]

(Product level)

Go down for approximately 200 mm (8"). The

displacer will move downwards until the freeze

command is given.

[Freeze] [Freeze]

(Product level)

Give the freeze command which stops the displacer

[Set to

operational

mode]

[Operational mode]

(Product level)

Restart in operational mode

When hereafter the displacer is free, and the weight is too high, the

force transducer must be recalibrated. When the measured displacer

weight is too far out of range, the gauge is probably not levelled within

2°. Then, improve the stability of the construction on which the gauge is

mounted.

11.2 Status Codes

The 954 SmartServo FlexLine provides information on the status of the

gauge. This might be errors or warnings, but the gauge can also

provide informational messages, e.g. to show that the gauge is in

performing a balance test.

On the SmartView, this information is visible as a code behind the

TII-SRV functions. In Engauge the display description is shown in the

status code of the Primary Value.

The primary value status shows the actual status. Additionally, each

function has a [Status history uncertain] and [Status history bad] list

that contains the last 10 warnings and errors that have occurred since

the last reset.

Note: if the actual status is GOOD, there is no actual error or warning

active, even though the history lists might show errors or

warnings!

Loading...

Loading...