OPERATION

Part No.: 4417340 Revision 1 Service Manual 253

954 SmartServo FlexLine

Simple audit trail functionality is implemented by recording several SAT

related parameters.

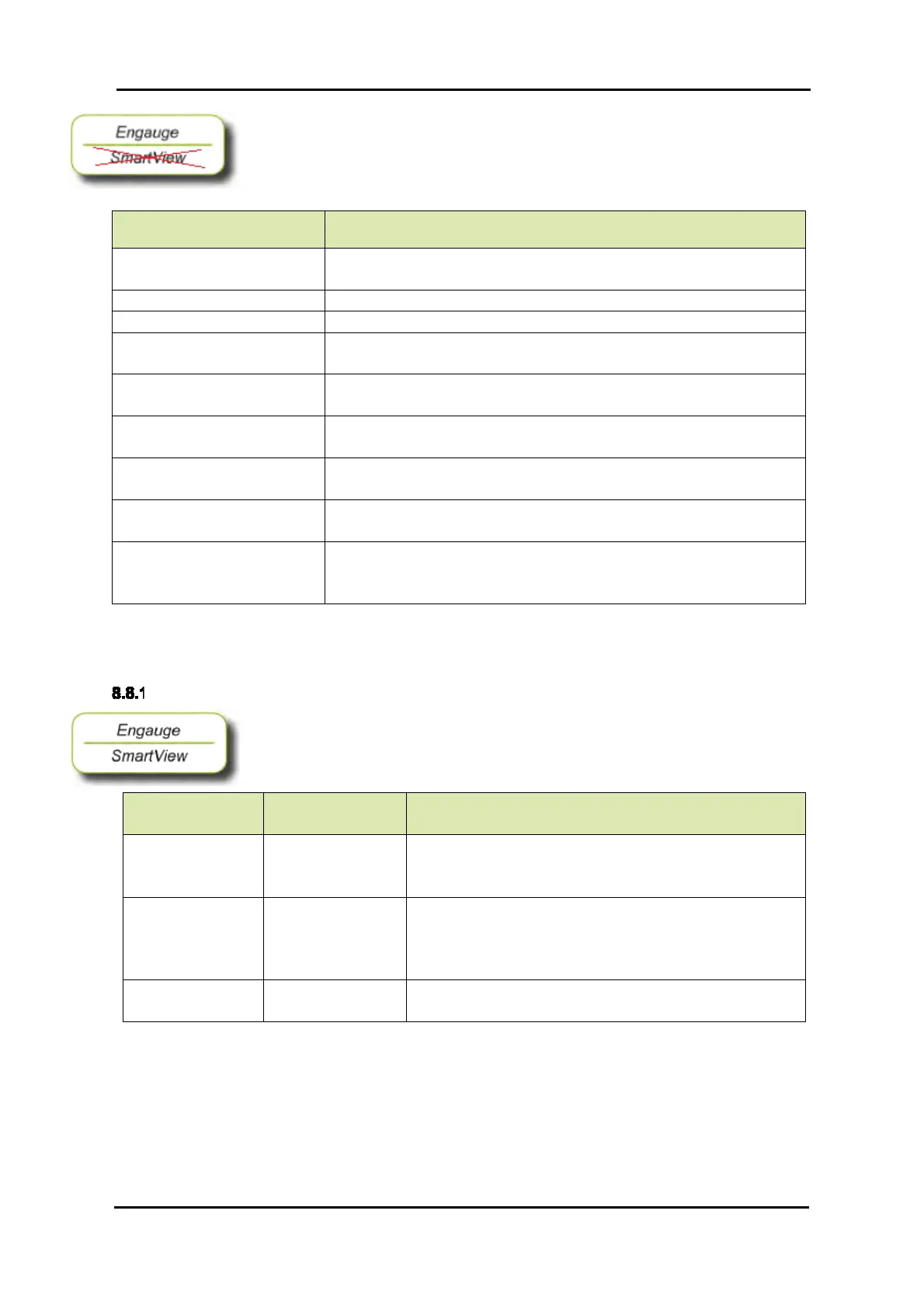

Entity name Description

< SAT status > Shows the status of the SAT (idle, 1st attempt, 2nd attempt, 3rd

attempt, denied, fail, success).

< SAT level last fail > Level at which a SAT last failed.

< SAT last level executed > Level at which the most recent SAT was performed.

< SAT minimum level

executed >

Lowest level at which a SAT has been performed since NOVRAM

initialization.

< SAT maximum level

executed >

Highest level at which a SAT has been performed since NOVRAM

initialization

< SAT highest number of

retries >

Highest number of retries observed during a SAT since NOVRAM

initialization.

< SAT number of executed

tests >

Total number of SATs performed since NOVRAM initialization.

< SAT time elapsed since

last SAT >

Number of minutes elapsed since the most recent SAT

successfully completed.

< SAT RTC last fail > Date and time of the last SAT fail.

Note: for useful information the Real Time Clock (RTC) needs to be

set correctly (refer to section 7.3.4

8.8 Verify level calibration

Verify level calibration against a tank top reference stop

When a tank adapter with a tank top reference stop is installed, the level

calibration of the 954 SmartServo FlexLine can be checked. Proceed as

follows:

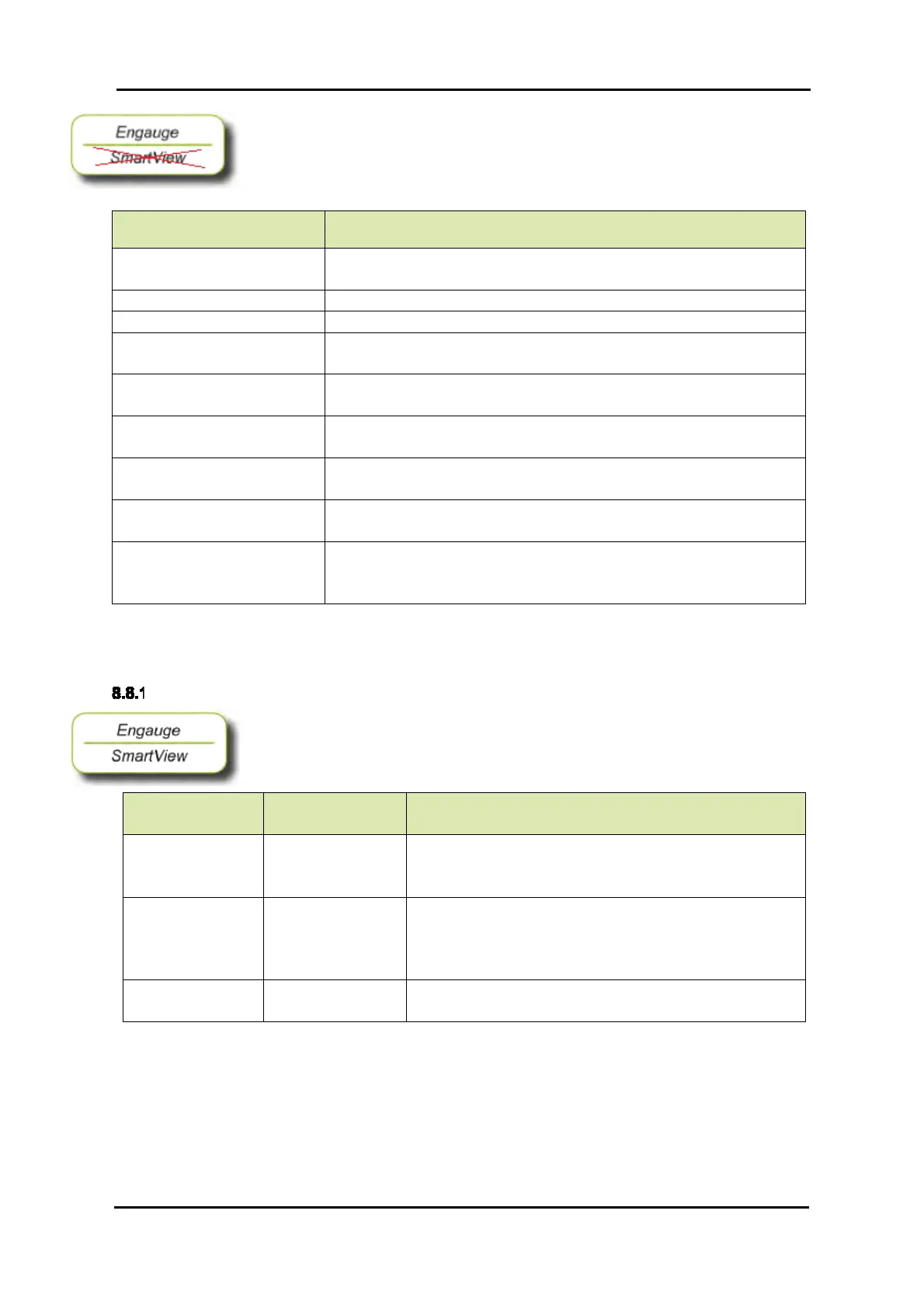

Entity name Entity name

(SmartView)

Description

[Calibrate] [Calibrate]

(Product level)

With this command the displacer is pulled up until it is

halted against the tank top reference. Wait until the

displacer is settled.

[Tank top level] [Tank top level]

(Product level)

Request for the tank top value, which was established

during level calibration. The level reading from the

gauge should not differ more than ±3 mm (±1/8") with

the value in entity [Tank top level].

[Unlock] [Unlock]

(Product level)

Give an unlock command to cancel the calibrate

command.

If the tank top value and the gauge reading differs more than the

specified value, the calibration procedure as described in section 7.6.2

should be repeated.

Loading...

Loading...