OPERATION

254 Service Manual Part No.: 4417340 Revision 1

954 SmartServo FlexLine

Verify level calibration on top of ball valve

If the top of the ball valve is used as reference point, the level calibration

of the 954 SmartServo FlexLine can be verified.

Make sure the servo auto test downwards is disabled, else the servo gauge will end

up in a SAT failure and will stop measuring level. Refer to section Error! Reference

source not found..

Proceed as follows:

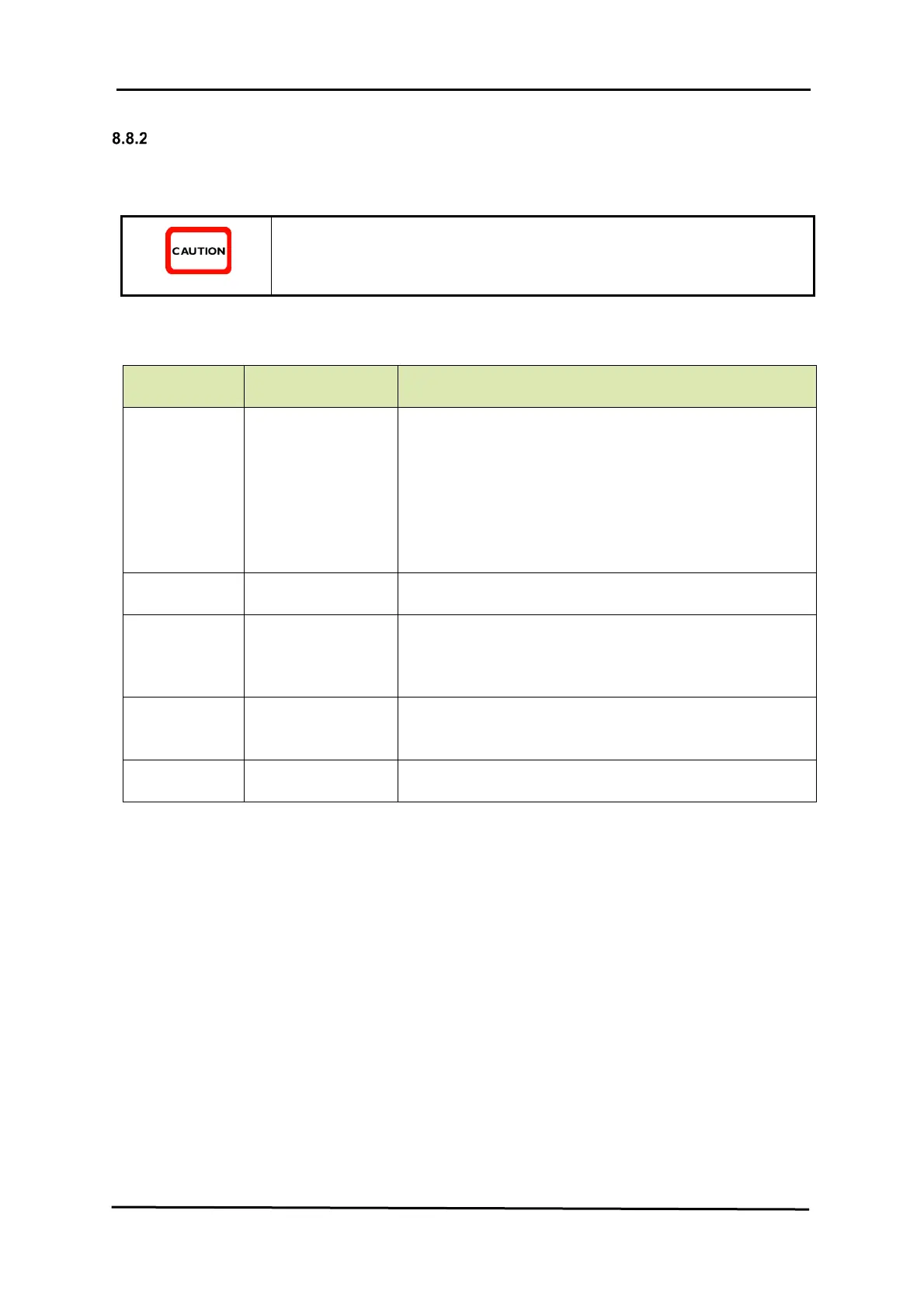

Entity name Entity name

(SmartView)

Description

[Calibrate]

[Calibrate]

(Product level)

The displacer will be raised until it stops against the flange

of the level gauge.

Caution

If a 45 mm displacer is used, immediately stop the

Calibrate command as soon as the displacer is above the

ball valve, followed by a freeze command.

Make sure the displacer is positioned above the ball valve.

Close the ball valve.

[Unlock]

[Unlock]

(Product level)

Unlock the gauge and wait the displacer reaches the top

of the ball valve.

[Reference level]

[Reference level]

(Product level)

Request for the reference level value, which was

established during calibration. The level reading from the

gauge should not differ more than ±2 mm (±1/16") with the

value in entity [Reference level].

[Calibrate]

[Calibrate]

(Product level)

The displacer will now raise from the ball valve. Let it stop

against the flange or give a freeze command.

Open the ball valve.

[Unlock]

[Unlock]

(Product level)

Unlock the gauge. The displacer will now move down till it

reaches the level

If the reference level value and the gauge reading differ more than the

specified value, the calibration procedure as described in section 7.6.3

should be repeated.

Loading...

Loading...