7 - 5

PN 074-550-P1C

SQC-310 Operating Manual

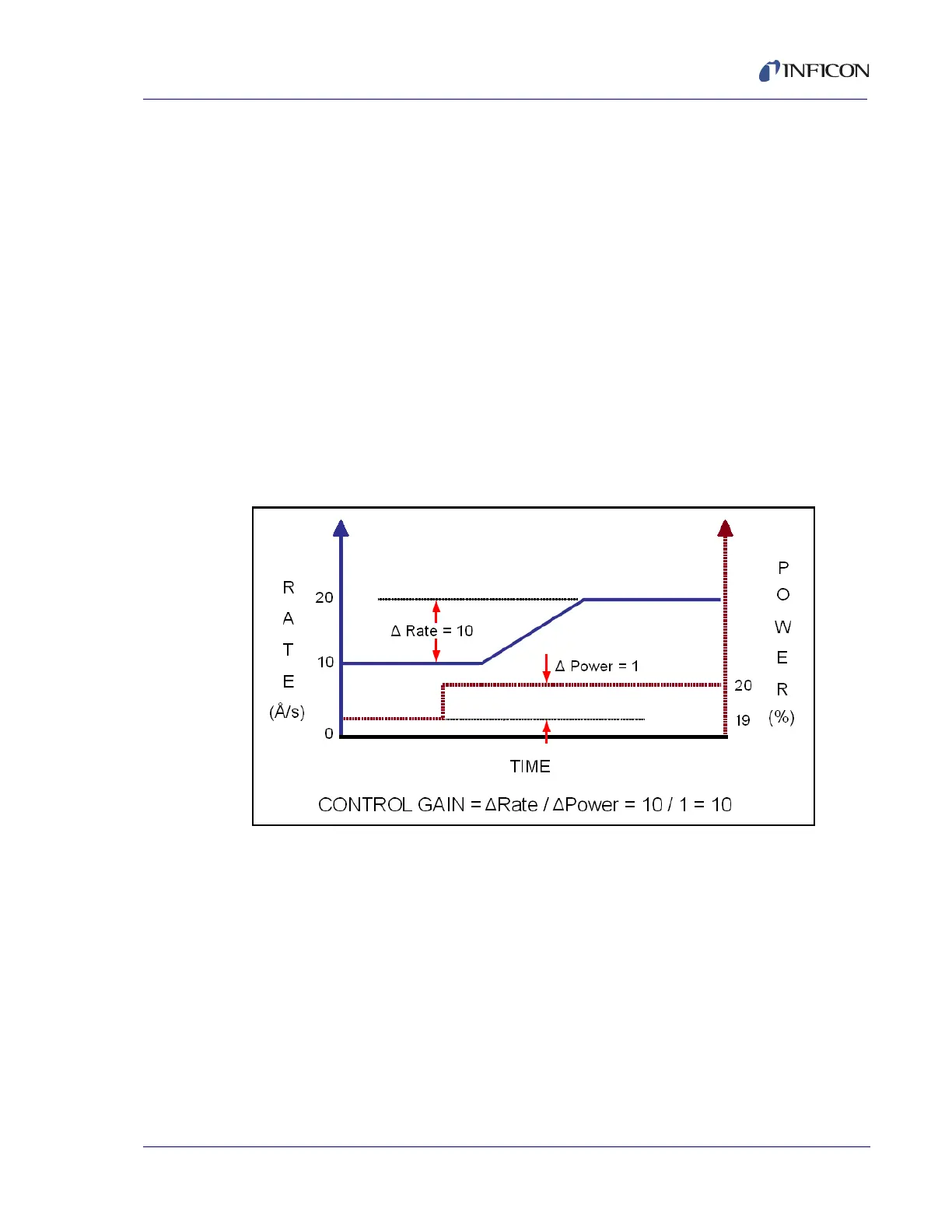

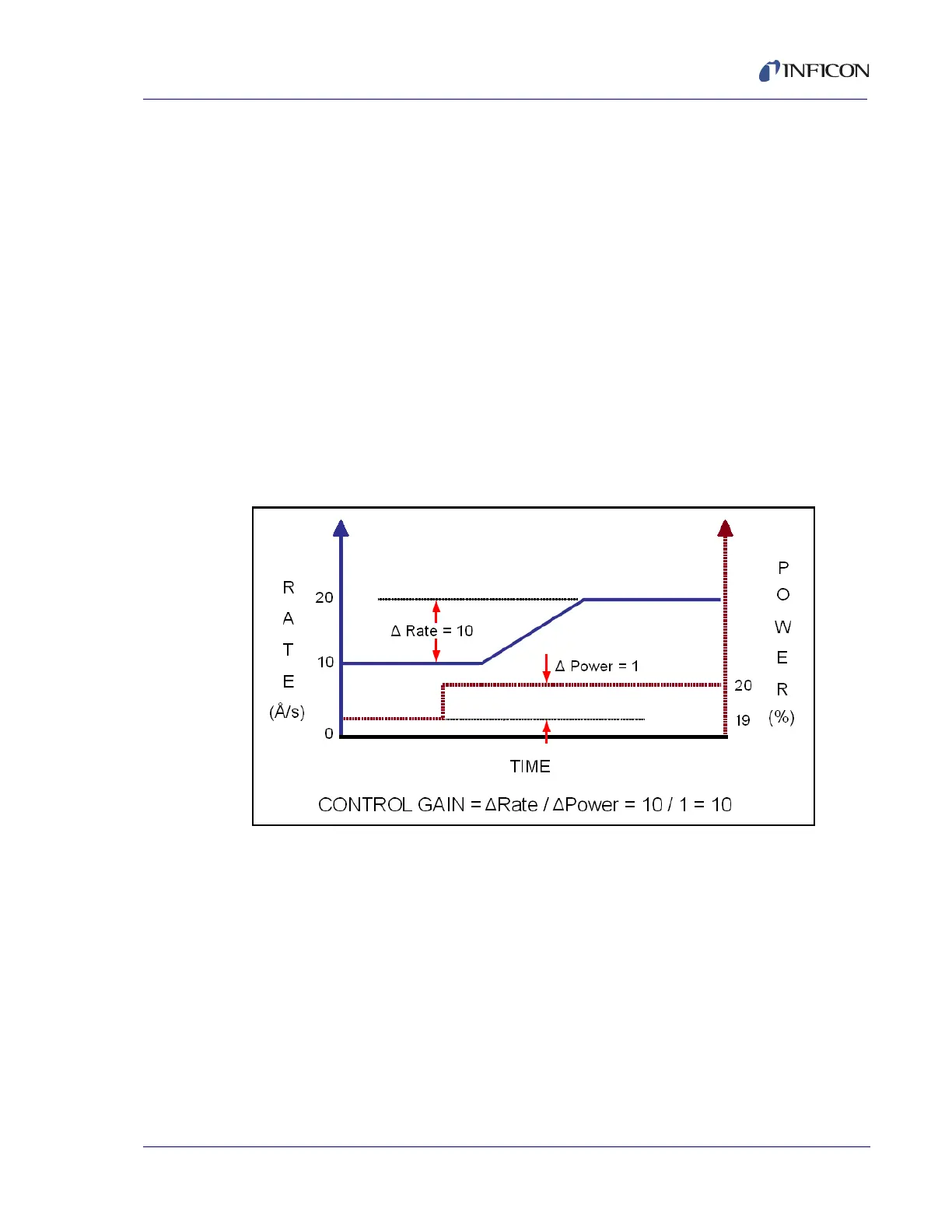

7.5 Control Loop

The function of the control loop parameters is to match the SQC-310 reaction to an

error (between the measured deposition rate and the desired rate) to the time

related characteristics of the deposition source and its power supply. There are

three adjustable parameters; P(proportional), I(integral) and D(derivative) used to

accomplish this. It is convenient to think of sources as falling into two categories

"fast" or "slow" (see section 7.5.1). The tuning parameters are affected by source

level, rate, sweep range or beam density, tooling and source condition.

The proportional gain (P-Term) parameter sets the rate at which the control voltage

changes in response to an error signal (see Figure 7-1). Any error in the rate

causes the source control voltage to ramp to a new value. When the source control

voltage increases or decreases to the correct value, the value required to achieve

the desired rate, the error goes to zero and the output remains constant. A higher

value for this term would be a more responsive (but potentially unstable) control

loop.

Figure 7-1 Proportional Gain

Loading...

Loading...