11 OPTION DACS-W Operation Manual

11-8

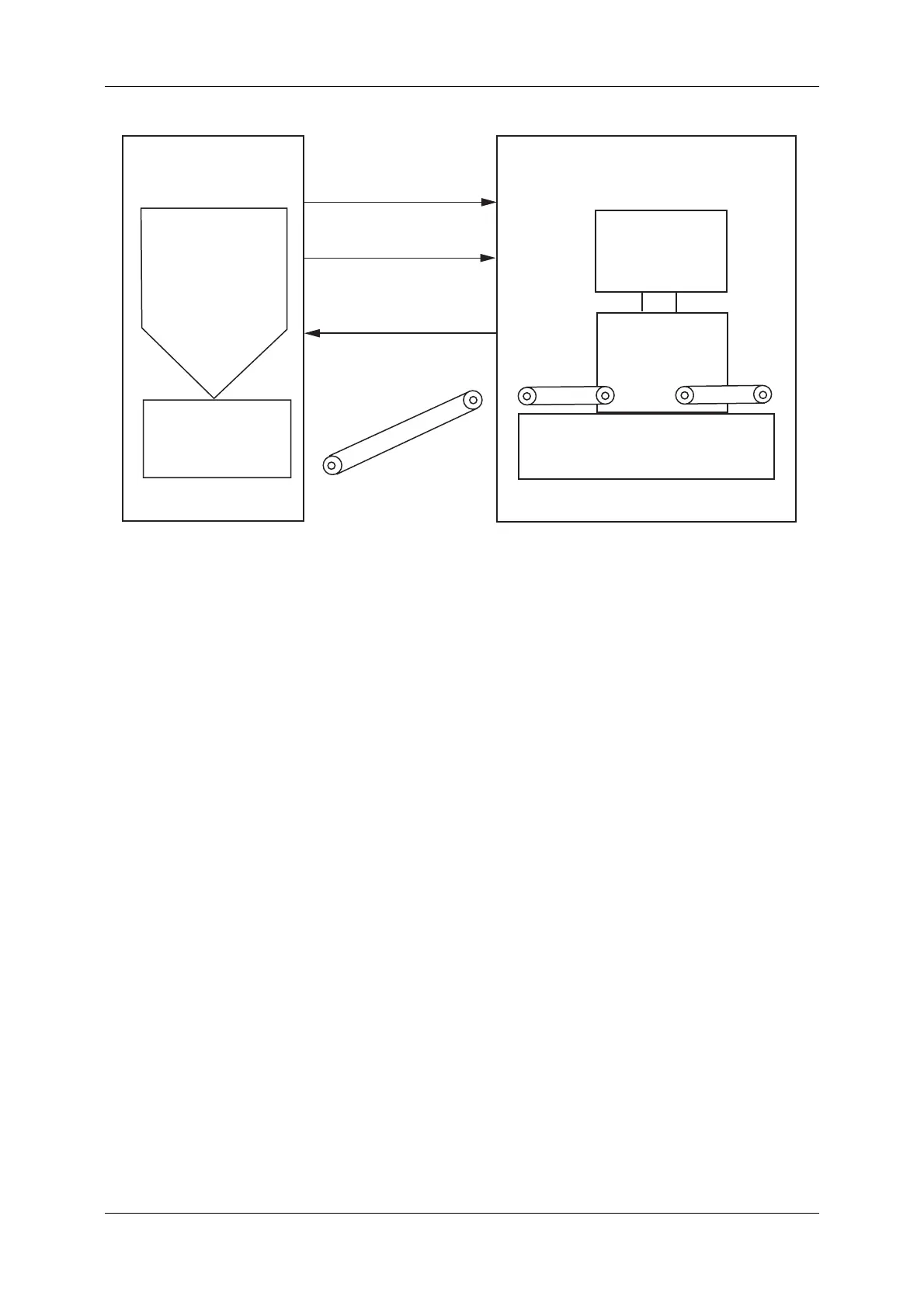

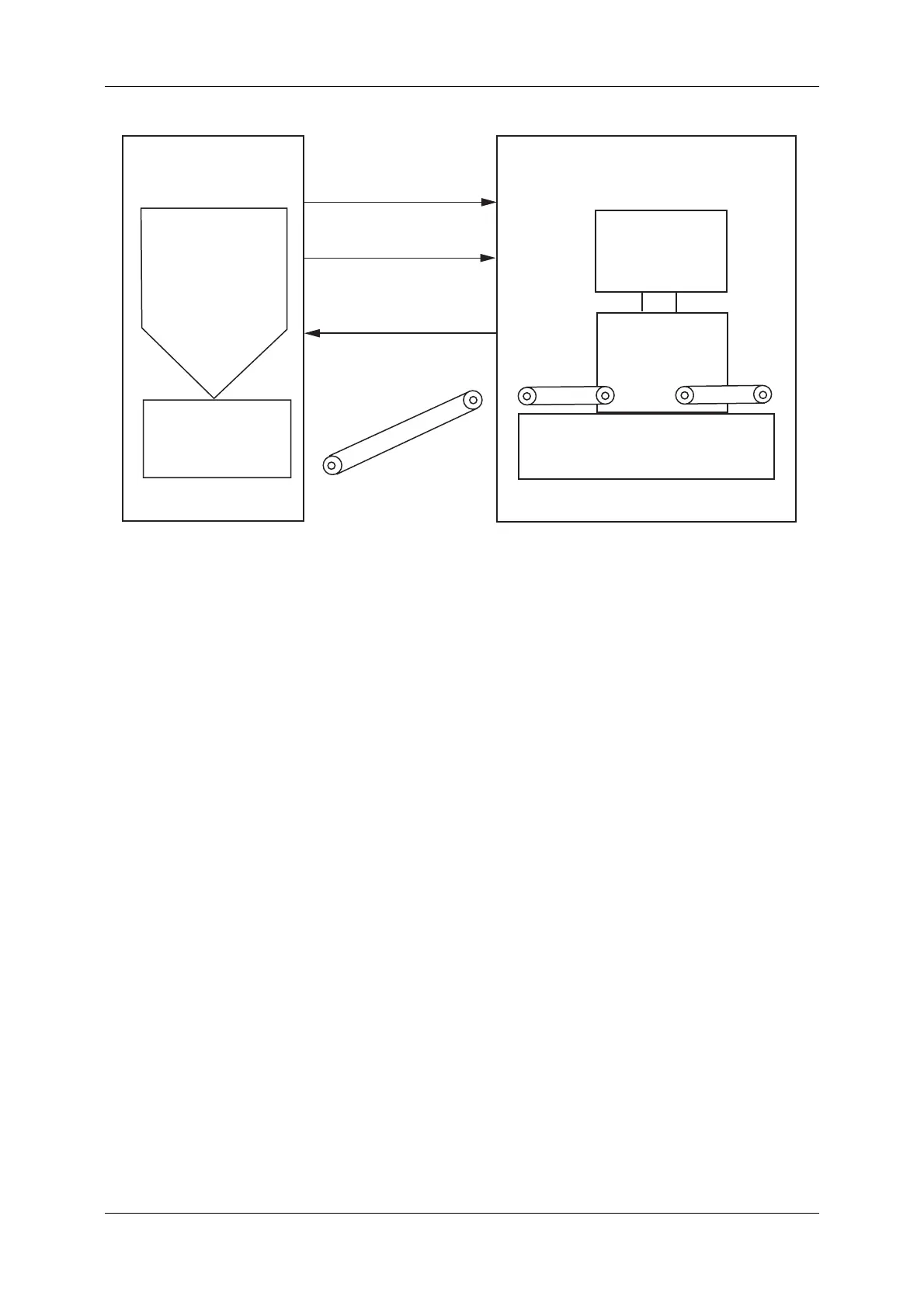

Figure 11-19 FEED BACK CONTROL OVERVIEW

As diagrammed above, the auger filler is controlled so that filler output achieves the Target Weight. The

sequence of control signals is as follows:

1. An Auger Ready signal is sent from the auger filler to the checkweigher.

2. An Auger Run signal is sent from the checkweigher to the auger filler to start filling.

Auger begins filling.

3. A proportional Auger Pulse signal (auger rotation angle) is sent from the auger filler to the

checkweigher.

4. The checkweigher registers the number of pulses received, and when the predetermined count is

reached, it terminates the Auger Run signal to stop filling.

The DACS-W checks the weight of the filled packs and judges whether the quantity is excessive or

insufficient. Based on this, the prescribed pulse count is increased or decreased to regulate auger filler

output.

11.2.2Status Display

A display showing FBC status for FBC option specifications was added and is accessed through the

status display sequence. To access this display continue pressing the INFO key until the FBC Status

Display appears.

FILLER SYSTEM

AUGER FILLER

AUGER PULSE SIGNAL

AUGER READY SIGNAL

AUGER RUN SIGNAL

PACKAGING

MACHINE

DACS-W

Loading...

Loading...