‒ Stop category 0 » STOP 0

‒ Stop category 1 » STOP 1

according to IEC 60204-1

• The values specified for Stop 0 are guide values determined by

means of tests and simulation. They are average values which con-

form to the requirements of DIN EN ISO 10218-1. The actual stopping

distances and stopping times may differ due to internal and external

influences on the braking torque. It is therefore advisable to determine

the exact stopping distances and stopping times where necessary un-

der the real conditions of the actual robot application.

• Measuring technique

The stopping distances were measured using the robot-internal meas-

uring technique.

• The wear on the brakes varies depending on the operating mode, ro-

bot application and the number of STOP 0 stops triggered. It is there-

fore advisable to check the stopping distance at least once a year.

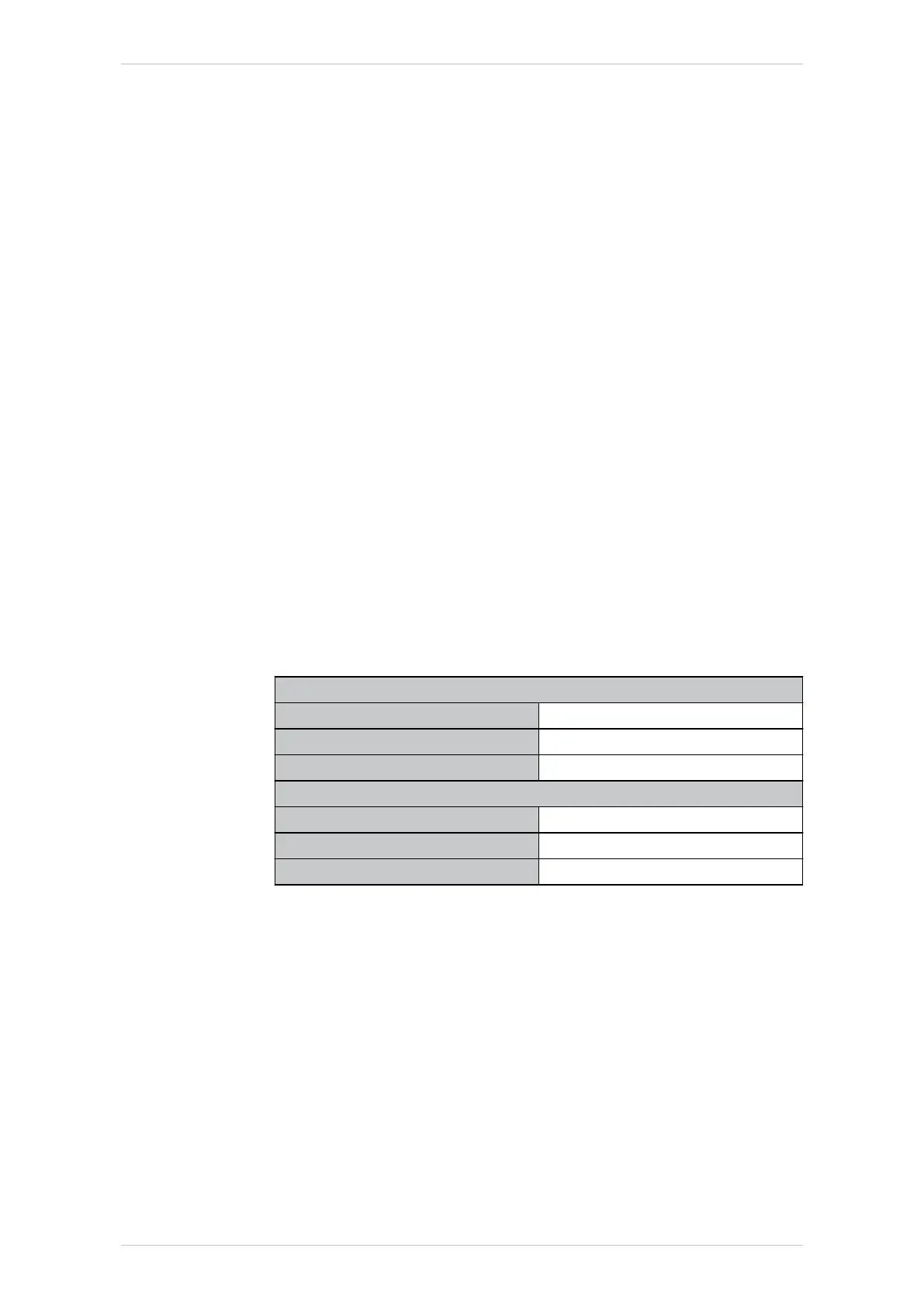

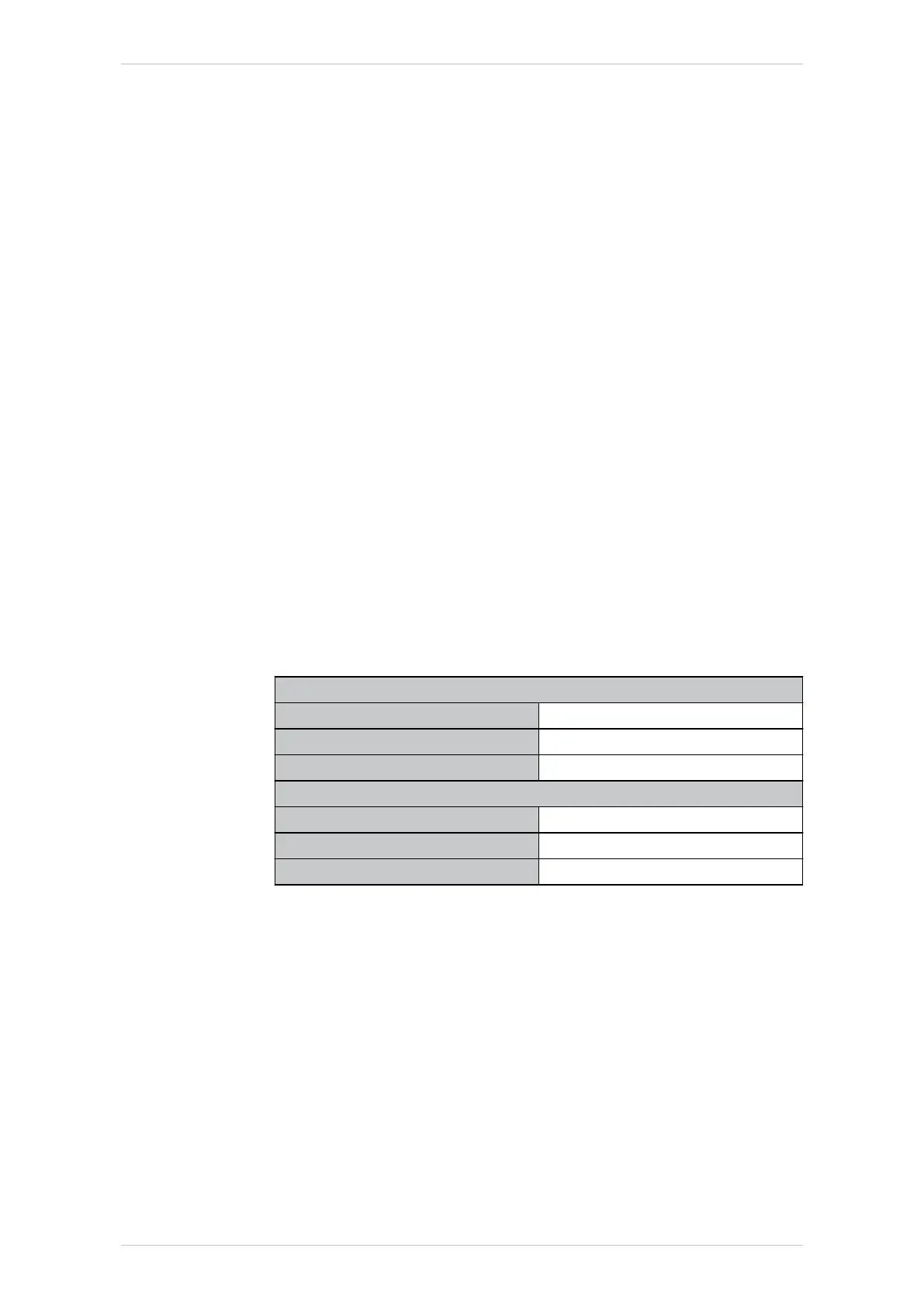

4.11.2 Stopping distances and times, KR 20 R3100

4.11.2.1 Stopping distances and stopping times, STOP 0, A1 to A3

The table shows the stopping distances and stopping times after a

STOP 0 (category 0 stop) is triggered. The values refer to the following

configuration:

• Extension l = 100%

• Program override POV = 100%

• Mass m = maximum load (rated load + supplementary load on arm)

Stopping distance

A1 30.47 °

A2 29.14 °

A3 16.79 °

Stopping time

A1 0.38 s

A2 0.42 s

A3 0.20 s

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021 www.kuka.com | 129/344

Technical data

Loading...

Loading...