10.2.2 Cleaning

Procedure

1. Shut down the robot.

2. If necessary, shut adjacent system components down and lock them.

3. Remove enclosures if this is necessary in order to carry out the clean-

ing work.

4. Clean the robot.

5. Fully remove all cleaning agents from the robot.

6. Clean any areas of corrosion and reapply corrosion protection.

7. Install any safety equipment that has been removed.

8. Put back in place any enclosures that have been removed.

10.2.3 Preparing for storage

Procedure

1. Perform a visual inspection of the robot.

2. Remove any foreign bodies.

3. Remove any corrosion.

4. Attach all covers to the robot and check that the seals are correctly in

place.

5. Seal off electrical connections with suitable covers.

6. Seal hose connections by suitable means.

7. Cover the robot with plastic film and seal it at the base frame against

dust.

If necessary, add a desiccant beneath the sheeting.

10.2.4 Concluding work

No concluding work is required.

10.3 Disposal

When the manipulator reaches the end of its useful life, it can be removed

from the system and dismantled, and the materials can be disposed of

properly by type.

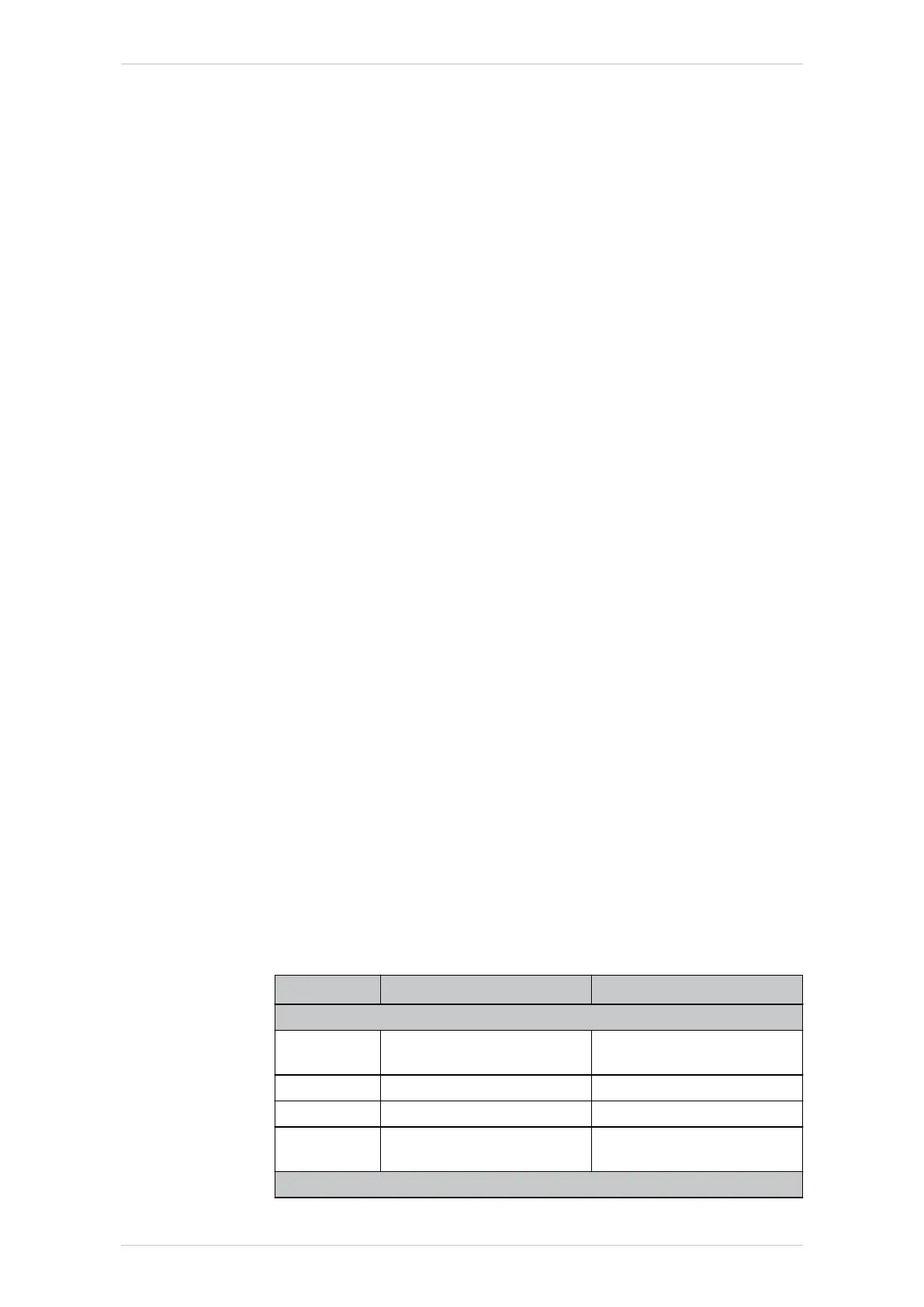

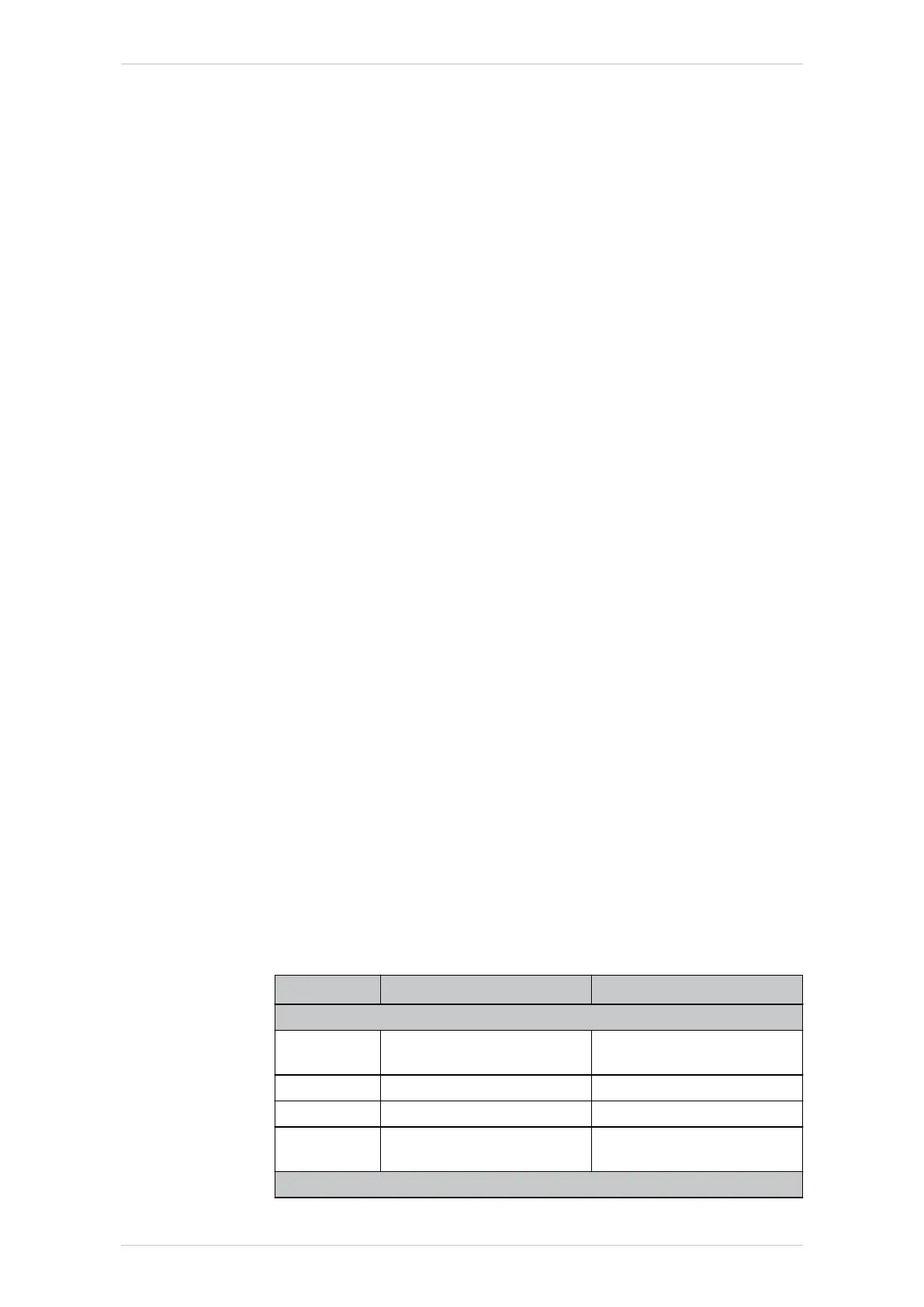

The following table provides an overview of the materials used in the ma-

nipulator. All plastic components are marked with a material designation

and must be disposed of accordingly.

Material Subassembly, component Additional information

Metal

Cast alumi-

num

Wrist, arm, link arm, rotat-

ing column

Copper Cables, wires

Cast steel Base frame

Steel Gear units, screws, wash-

ers, metal covers, stops

Electrical parts

KR IONTEC

316/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Decommissioning, storage and disposal

Loading...

Loading...