8.7.2 Filling gear unit A5 with gear oil

Procedure

1. Move the robot to the specified axis position. The positions of axes A2

and A3 must produce 0° and axis A4 must be at -77° so that the oil

level can be checked (>>> "Axis position for checking the fill level on

A4" Page 209).

2. Clean both M10x1.0 magnetic screw plugs and check the sealing ele-

ment; exchange magnetic screw plugs if damaged (>>> 8.7.2 "Filling

gear unit A5 with gear oil" Page 212).

3. Connect the oil pump to the oil filler hole.

4. Fill the amount of oil up to the lower edge of the inspection hole =

vent hole, and insert and tighten the M10x1.0 magnetic screw plug;

M

A

= 7.5 Nm.

5. Remove the oil pump, and insert and tighten the M10x1.0 magnetic

screw plug; M

A

= 7.5 Nm.

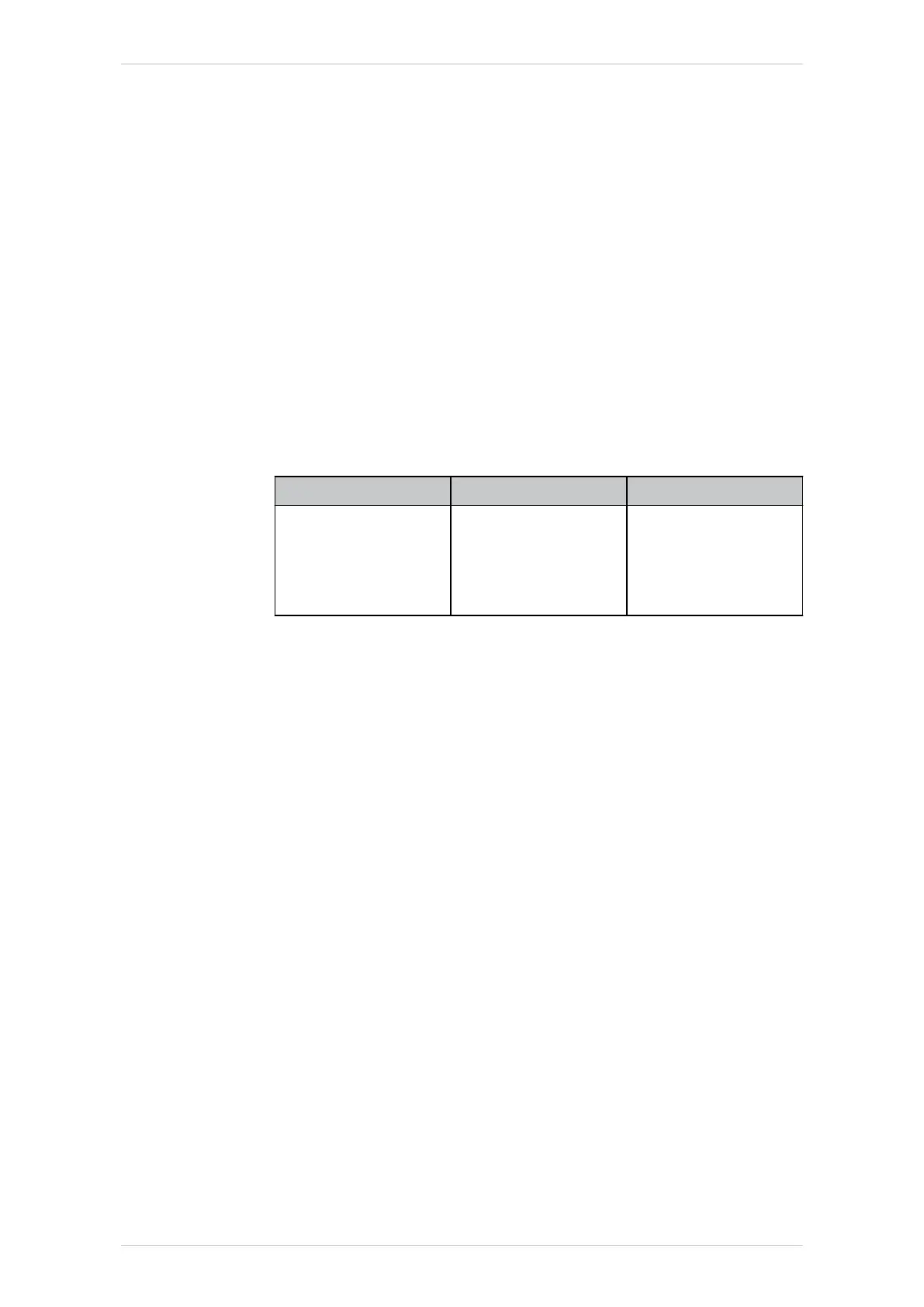

Axis position for checking the fill level on A5

Model Fill level Axis position

KR 30/50/70 R2100

KR 50 R2500

KR 50 R2500 F

KR 70 R2100 F

A5 A2 + A3 = 0 °

A4 = -77°

KR IONTEC

212/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Maintenance

Loading...

Loading...