When the screws are first slackened they must be replaced with new

ones.

Precondition

• The robot is accessible in the area of axis 1

Work safety

WARNING

Danger to life and limb due to unintended robot motions

Unintended robot motions may result in death, severe injuries and dam-

age to property.

• Secure the robot by pressing the EMERGENCY STOP device.

• Warn all persons concerned before starting to put it back into opera-

tion.

WARNING

Direct contact with cable grease may have an adverse effect on health.

Wear protective gloves and personal protective equipment. The general

safety instructions and the safety data sheet must be observed.

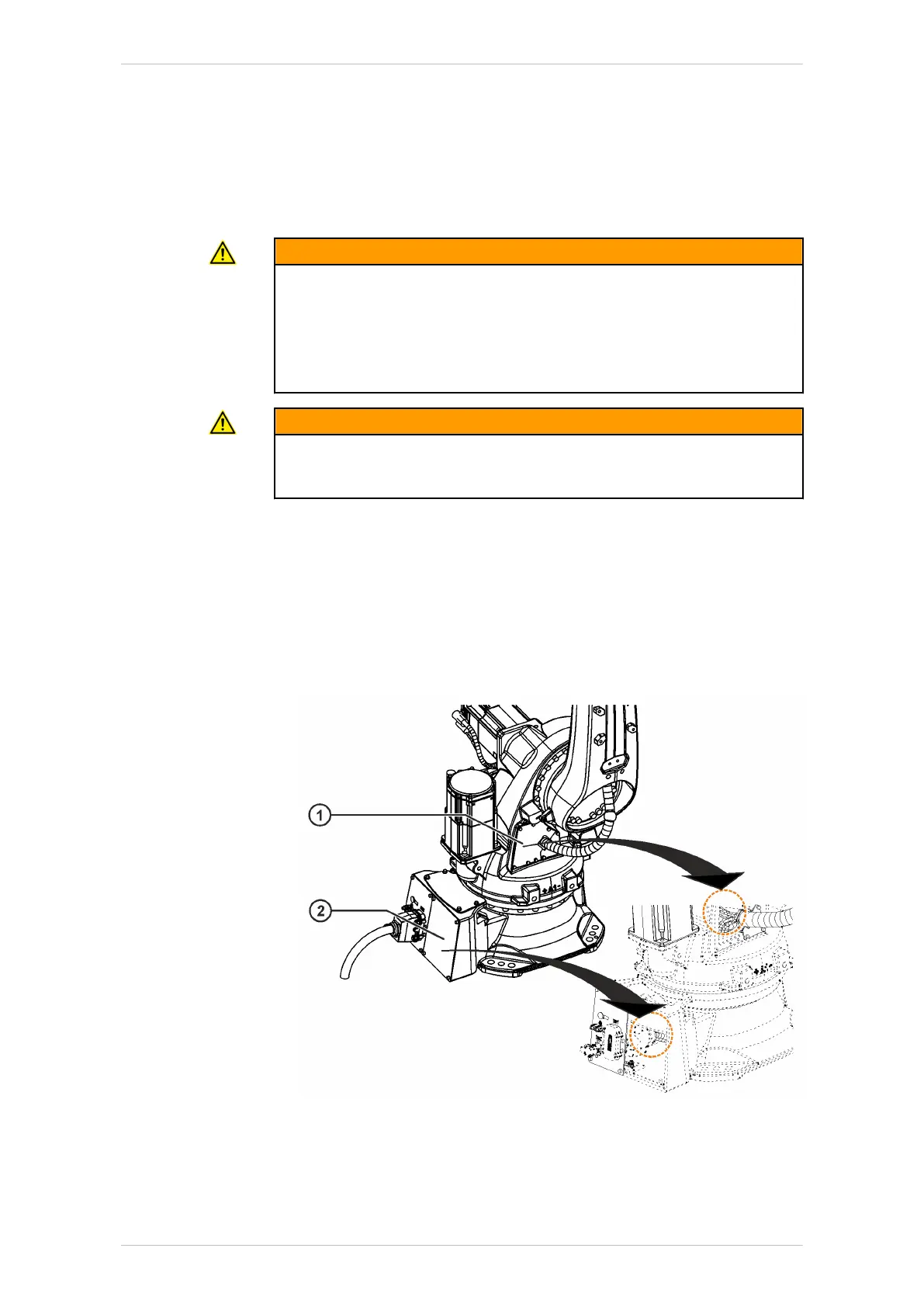

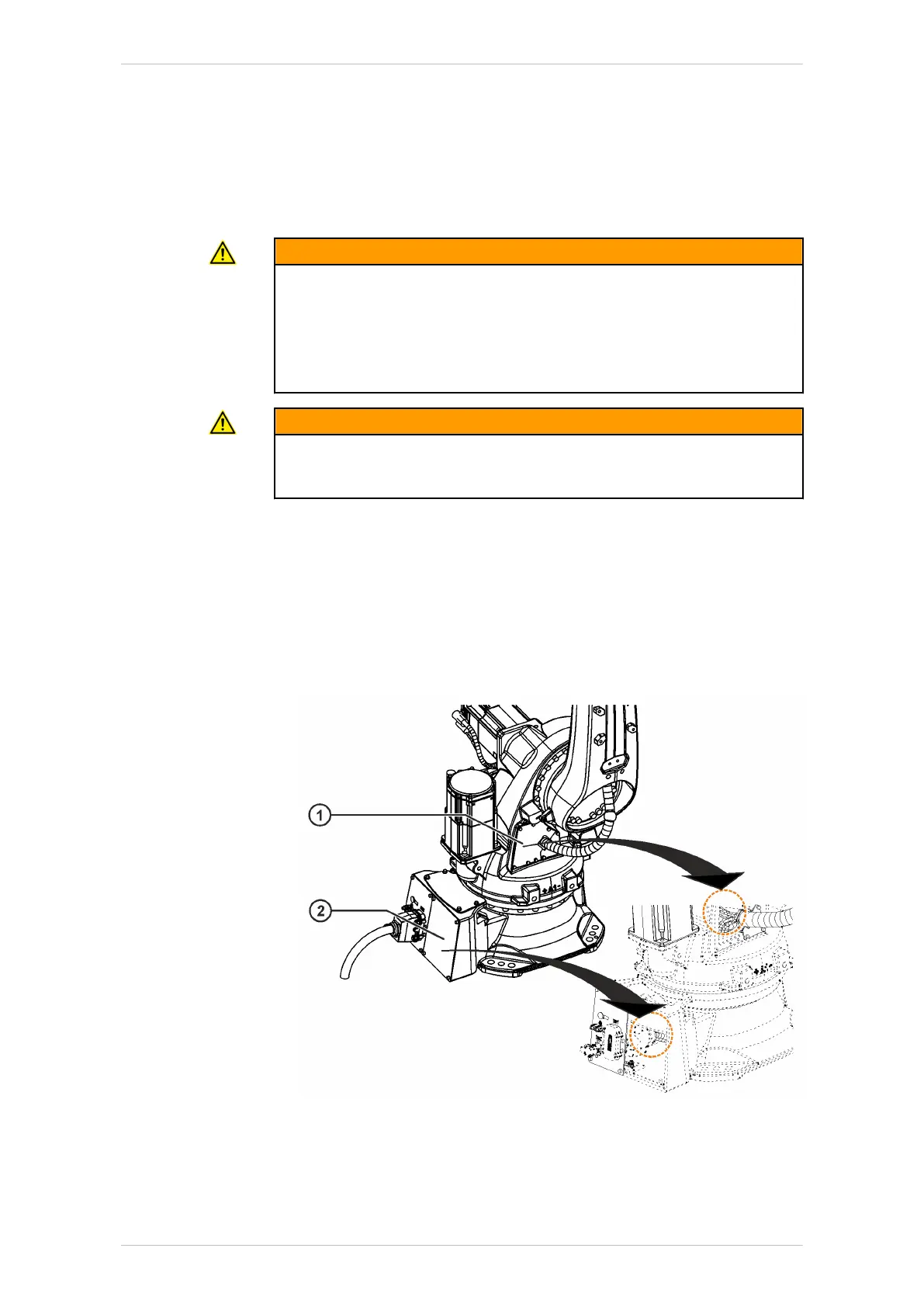

8.2.1 Checking and greasing cable set A1

Procedure

1. Unscrew 6 M6x12-8.8-A2K Allen screws from the large cover plate on

the rotating column and carefully remove it.

2. Unscrew 4 M6x12-8.8-A2K Allen screws from the cover plate on the

base frame and carefully remove it.

Fig. 8-3: Greasing cable A1

1 Cover plate on rotating column

2 Cover plate on base frame

KR IONTEC

196/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Maintenance

Loading...

Loading...