Interval Item Activity Auxiliary substances and

consumables

20,000 h

or 5 years

at the latest

6 Perform oil change on

gear unit A3.

(>>> 8.5 "Oil change in A3"

Page 203)

Optigear ALR 320

Initial filling quantity: 1.00 l

20,000 h

or 5 years

at the latest

7 Perform oil change on

gear unit A2.

(>>> 8.4 "Oil change in A2"

Page 200)

Optigear ALR 320

Initial filling quantity: 2.49 l

20,000 h

or 5 years

at the latest

8 Perform oil change on

gear unit A1.

(>>> 8.3 "Oil change in A1"

Page 197)

Optigear ALR 320

Initial filling quantity: 5.66 l

Up-to-date safety data sheets must be requested from the manufacturers

of auxiliary and operating materials. Further information about the auxiliary

substances and consumables used can be found under:

(>>> 12.2 "Auxiliary and operating materials used" Page 336)

The service life of the cable set corresponds to that of the robot, provi-

ded that programs are executed in the normal range. If, however, the

programs are at the limits, the service life of the cable set is reduced

and it may be necessary to exchange the cable set prematurely.

8.1.2 Maintenance table, KR IONTEC standard and Foundry variants

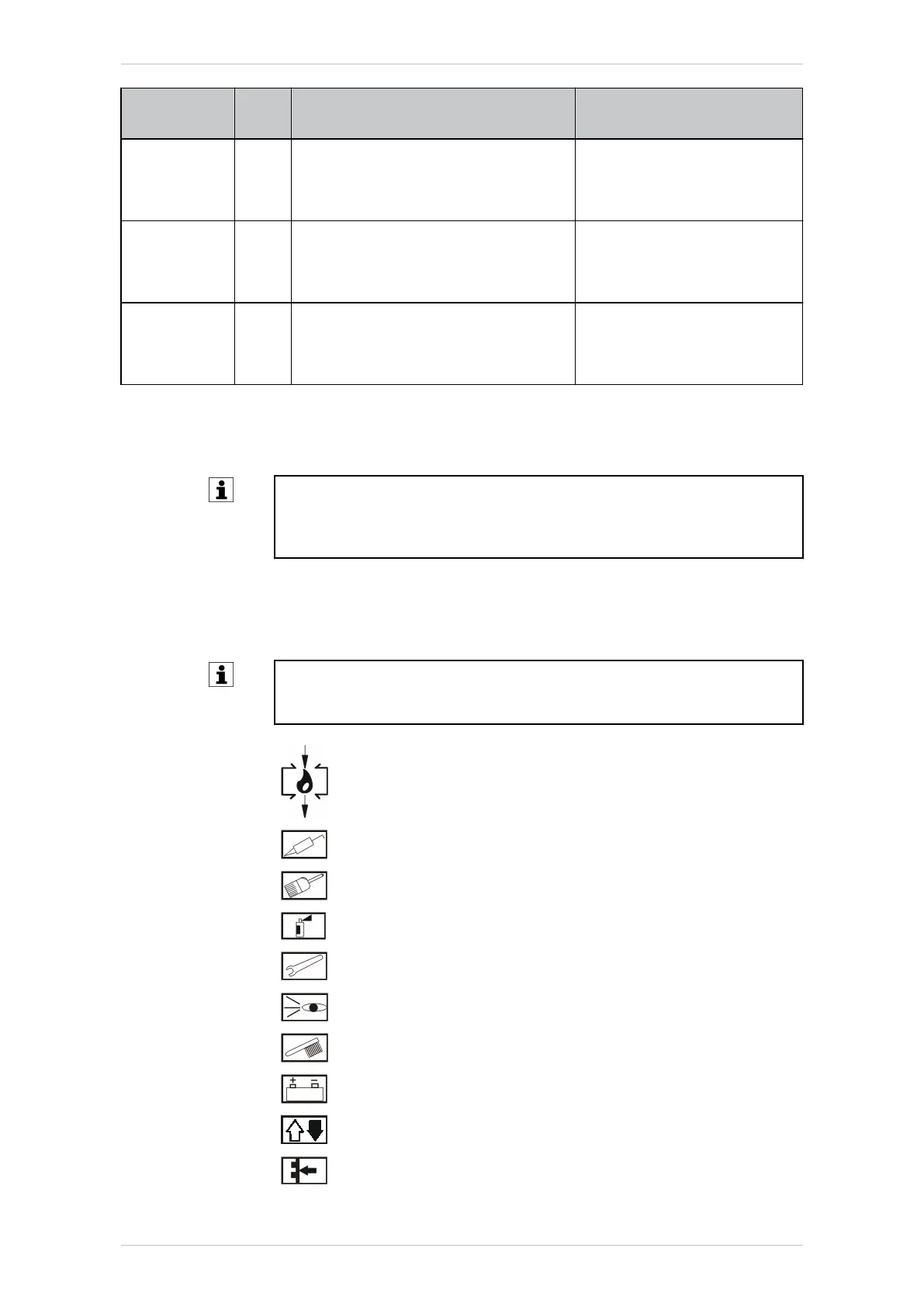

Maintenance symbols

The overview may contain maintenance symbols that are not relevant

for the maintenance work on this product. The maintenance illustrations

provide an overview of the relevant maintenance work.

Oil change

Lubricate with grease gun

Lubricate with brush

Lubricate with spray grease

Tighten screw/nut

Check component, visual inspection

Clean component

Exchange battery

Exchange component

Check toothed belt tension

KR IONTEC

192/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Maintenance

Loading...

Loading...