regular visual inspections may allow timely detection of changes. The na-

ture and scope of the maintenance work depend very much on the specif-

ic area of application. This enables early detection of damage, thereby

preventing failure of components and assemblies. Exchange damaged

components or assemblies.

Disposal

When the option reaches the end of its useful life, it can be removed and

disposed of. The materials must be disposed of in accordance with the

pertinent regulations and, where possible, separated and sorted for recy-

cling.

11.5.1 Starting up PURGE option D

Description

The PURGE option can be used to prepare compressed air for cleaning

purposes.

This section describes all work required to put PURGE option D into oper-

ation.

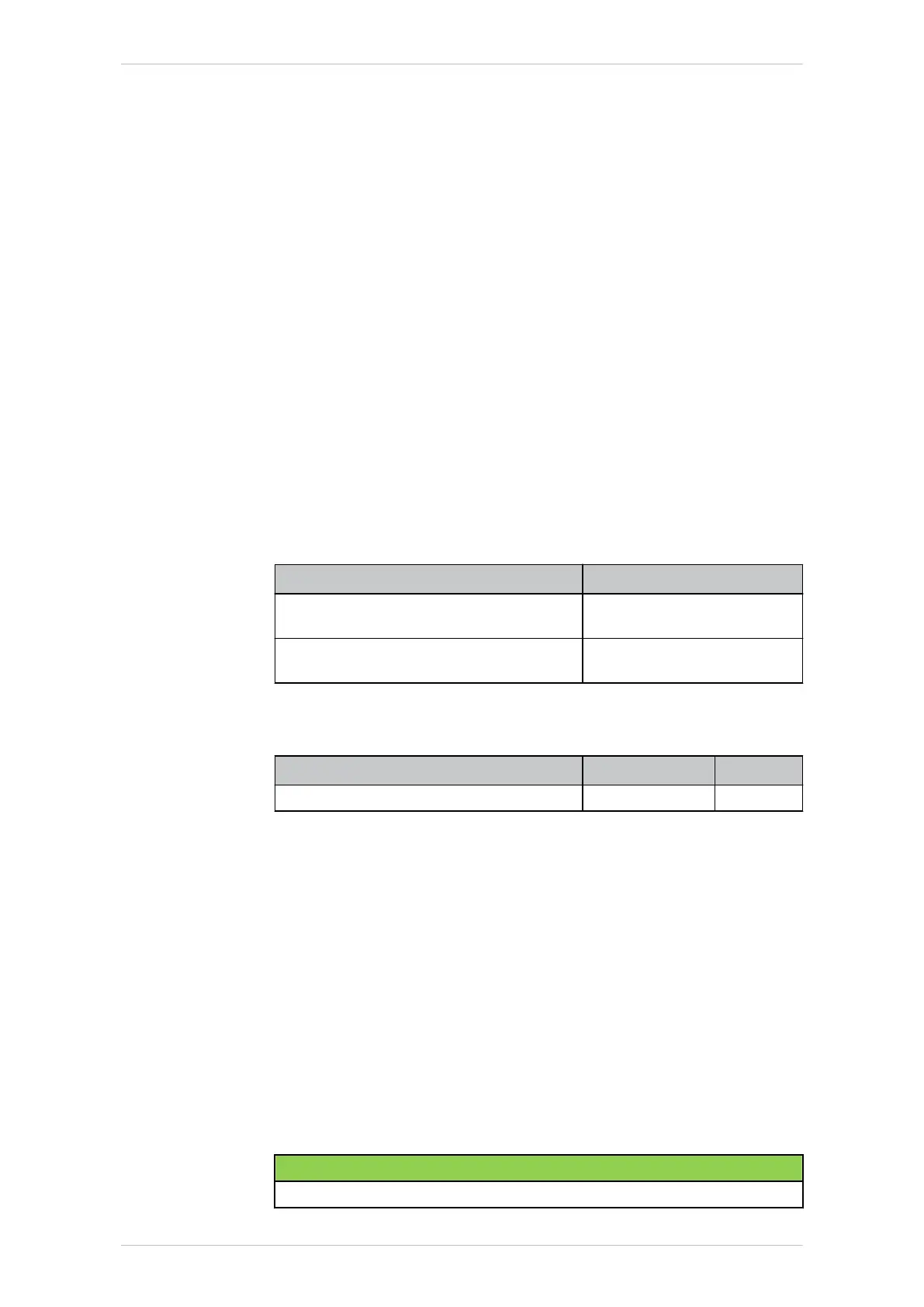

Equipment

The following equipment is required:

Designation Article number

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

5 Nm to 50 Nm

-

Material

The following material is required:

Designation Article number Quantity

PURGE Option D 0000-363-927 1

Tightening torques

The tightening torques can be found under: (>>> 12.1 "Tightening

torques" Page 335)

These are valid for screws and nuts where no other specifications are giv-

en.

Screws of strength class 10.9 and higher as well as screws with test cer-

tification may only be tightened once with the rated tightening torque.

When the screws are first slackened they must be replaced with new

ones.

Precondition

• The robot controller is switched off.

• The robot is freely accessible.

Work safety

SAFETY INSTRUCTION

The following procedure must be followed exactly!

KR IONTEC

332/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Options

Loading...

Loading...