9. Tighten 4 M10x25-8.8-A2K Allen screws with a torque wrench in diag-

onally opposite sequence. Increase the tightening torque to the speci-

fied value in several stages.

10. Plug connectors XM2 and XP2 into the right-angle connectors. The

pins and coding elements of the connectors must be taken into con-

sideration. When inserting the connectors, turn them until they clearly

lock into the coding elements (twist-proof).

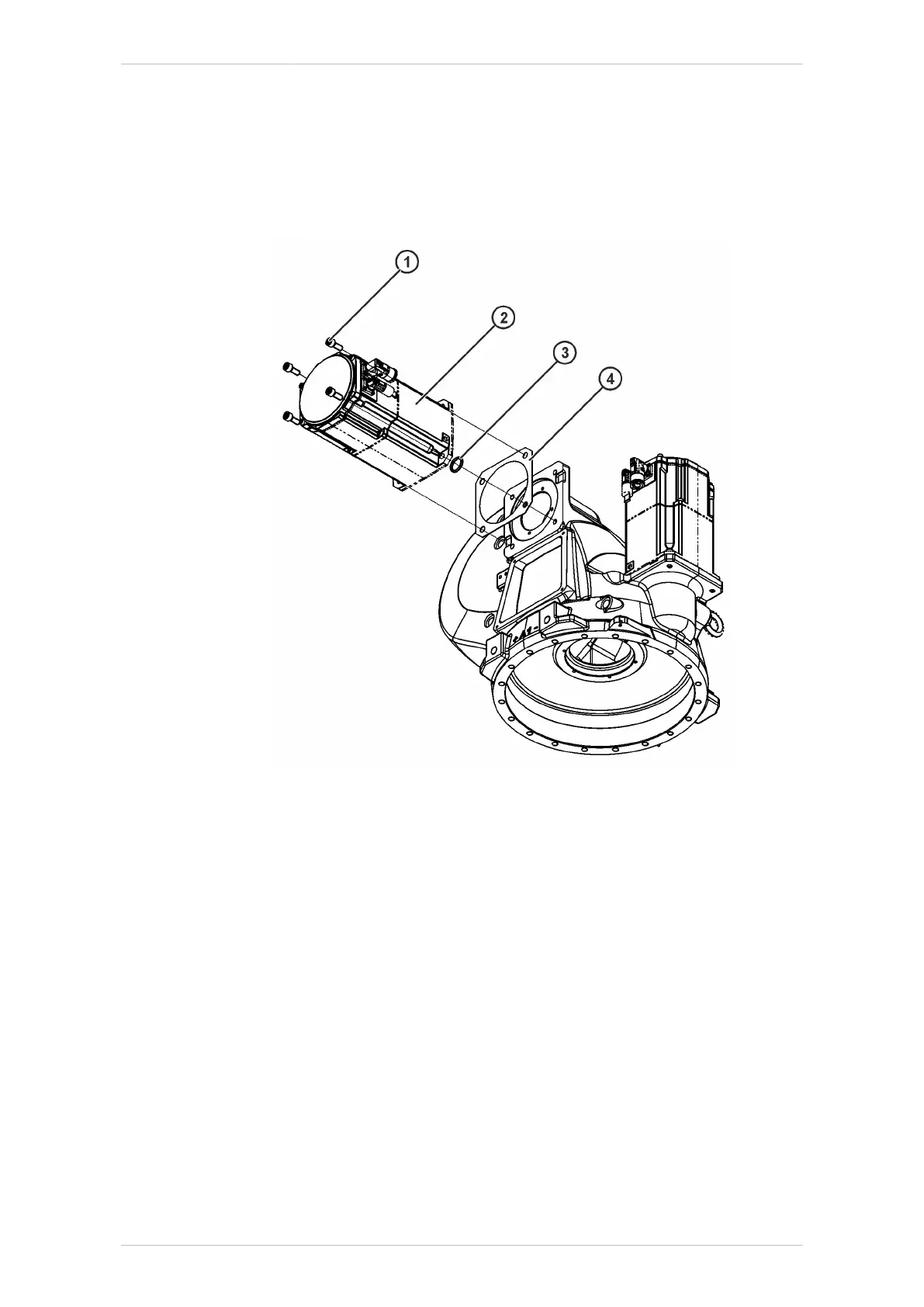

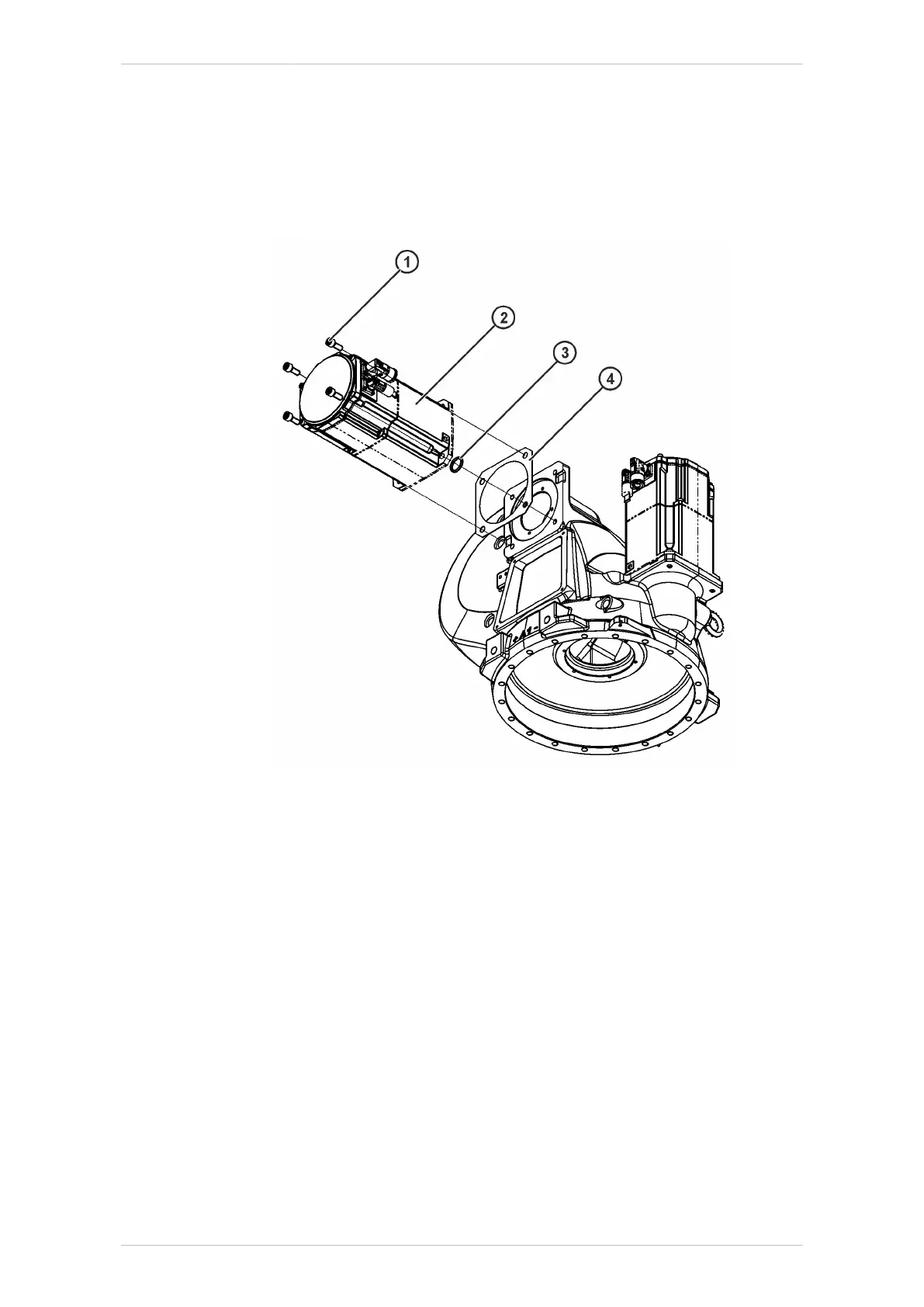

Fig. 9-17: Motor A2

1 M10x25-8.8-A2K Allen screw (4x)

2 Motor A2

3 O-ring 23x4

4 Seal

9.4.2.4 Removing the equipment securing the link arm

Procedure

1. Slacken the rope sling and detach from the crane.

2. Remove the rope sling from the robot.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021 www.kuka.com | 255/344

Repair

Loading...

Loading...