7 M6x35-8.8-A2K Allen screw with conical spring washer (18x)

7. Pull the sinuous spring off the motor.

8. If the motor is not to be reinstalled, it must be disposed of properly or

protected against corrosion before being put into storage.

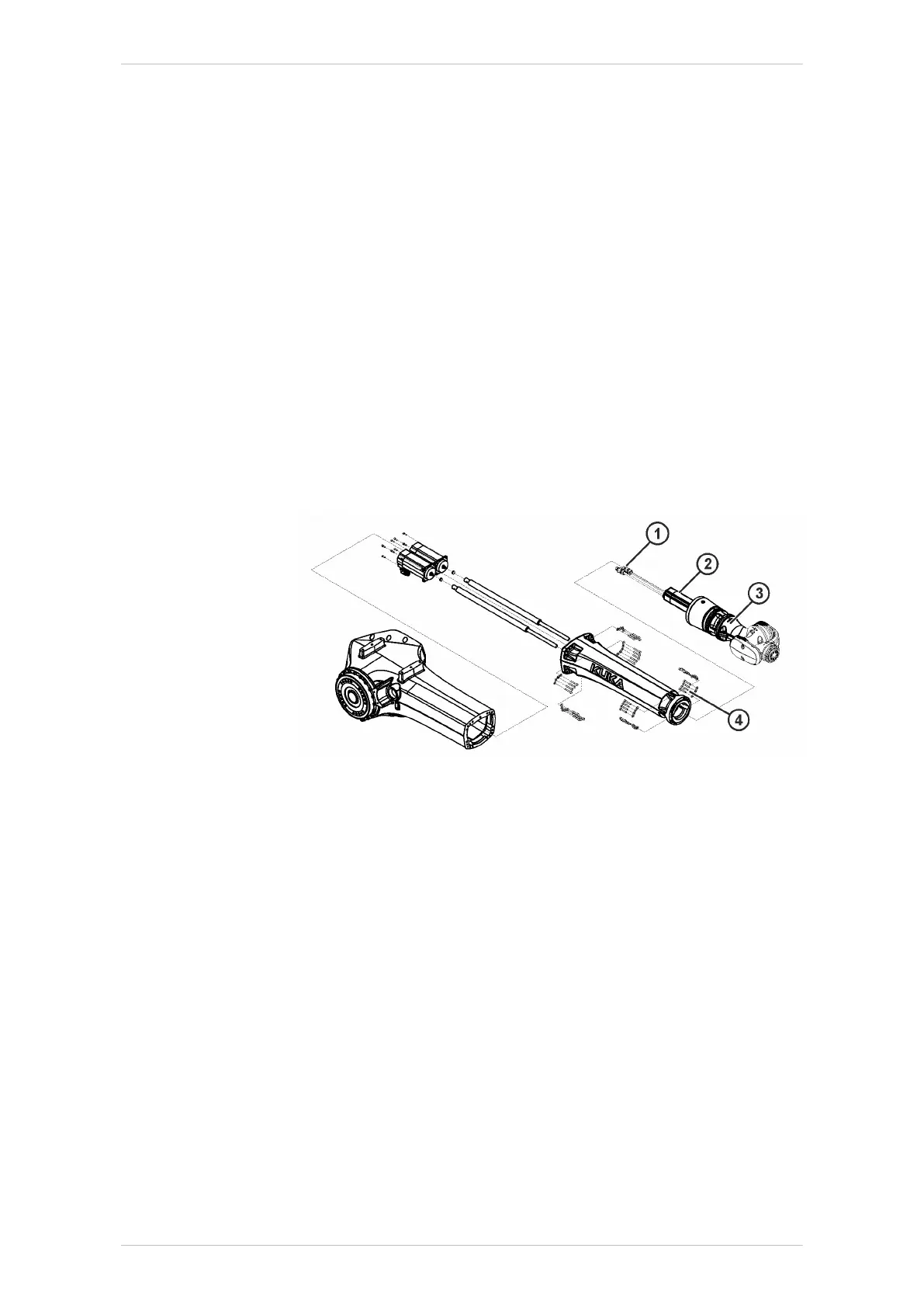

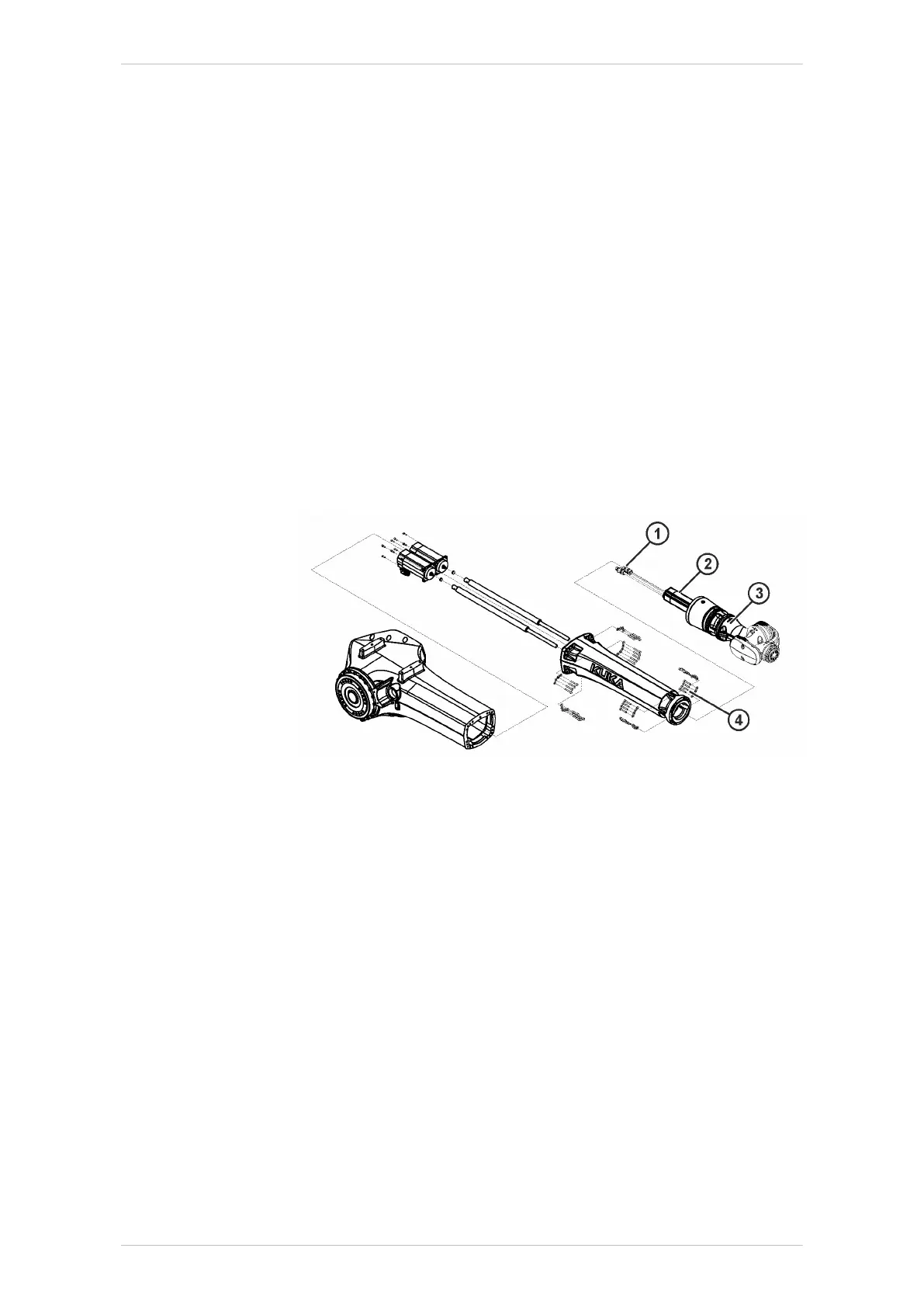

9.5.3.5 Removing motor A6 and in-line wrist

Procedure

1. Pull the connecting shafts out of the arm extension.

2. Unscrew 2 M6x12-8.8-A2K Allen screws from the cable holder of mo-

tor cable A6 and detach from the arm extension.

Unscrew 16 M6x35-8.8-A2K Allen screws from the arm extension and

remove the in-line wrist from the arm extension.

3. Release and unplug connectors XM6 and XP6 at the right-angle con-

nectors.

4. Release motor A6 and pull it out of the in-line wrist, being careful not

to tilt it.

5. Pull the sinuous spring off the motor.

Fig. 9-37: KR 20 R3100 – Removing/installing motor A6

1 Connectors XM6 and XP6

2 Motor A6

3 In-line wrist

4 M6x35-8.8-A2K Allen screws with conical spring washers (16x)

6. If the motor is not to be reinstalled, it must be disposed of properly or

protected against corrosion before being put into storage.

9.5.3.6 Preparing the new in-line wrist

Procedure

1. Remove all protective coatings and oil from new in-line wrist, if appli-

cable.

2. Clean all toothing before installation and apply a thin but continuous

coat of Microlube 261.

KR IONTEC

278/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Repair

Loading...

Loading...