9. Tighten 4 M10x25-8.8-A2K Allen screws with a torque wrench in diag-

onally opposite sequence. Increase the tightening torque to the speci-

fied value in several stages.

10. Plug connectors XM1 and XP1 into the right-angle connectors. The

pins and coding elements of the connectors must be taken into con-

sideration. When inserting the connectors, turn them until they clearly

lock into the coding elements (twist-proof).

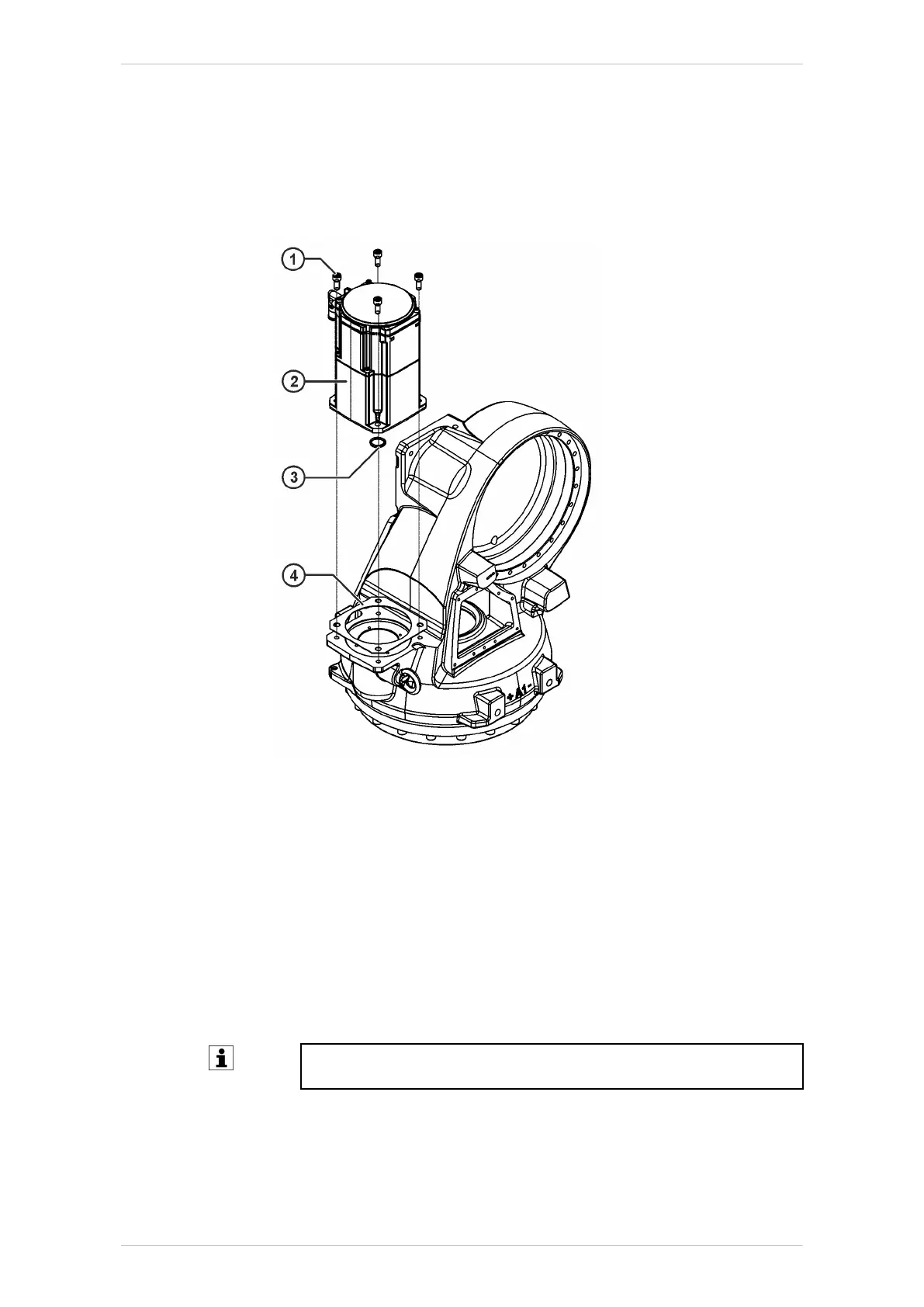

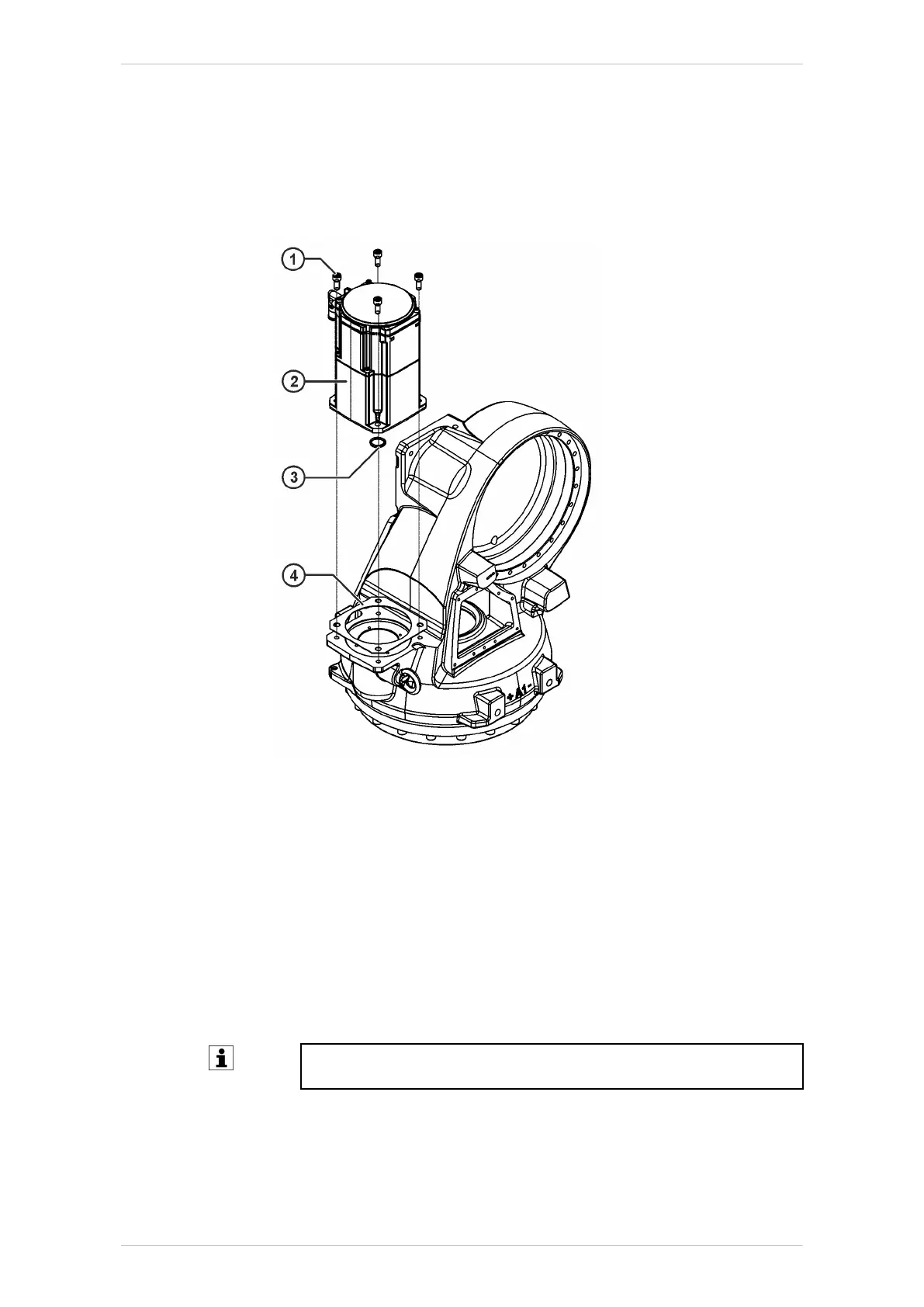

Fig. 9-14: Motor A1 Foundry

1 M10x25-8.8-A2K Allen screw (4x)

2 Motor A1

3 O-ring 23x4

4 Seal

9.4.1.3 Concluding work

The following concluding work must be carried out:

• Move A1 of the robot and look out for irregularities.

• Carry out mastering of A1.

Detailed information about mastering is contained in the operating

and programming instructions for end users or system integrators.

KR IONTEC

250/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Repair

Loading...

Loading...