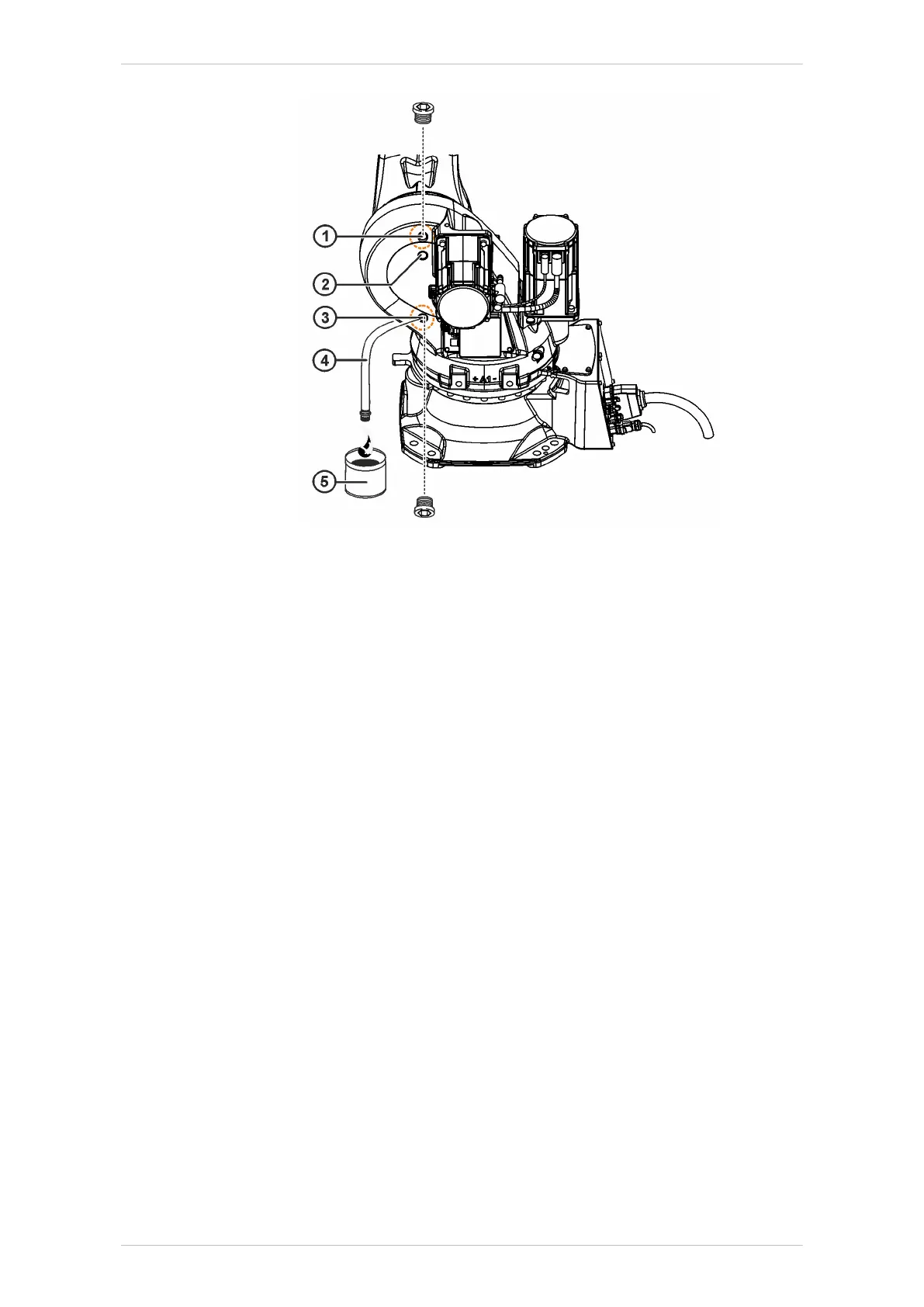

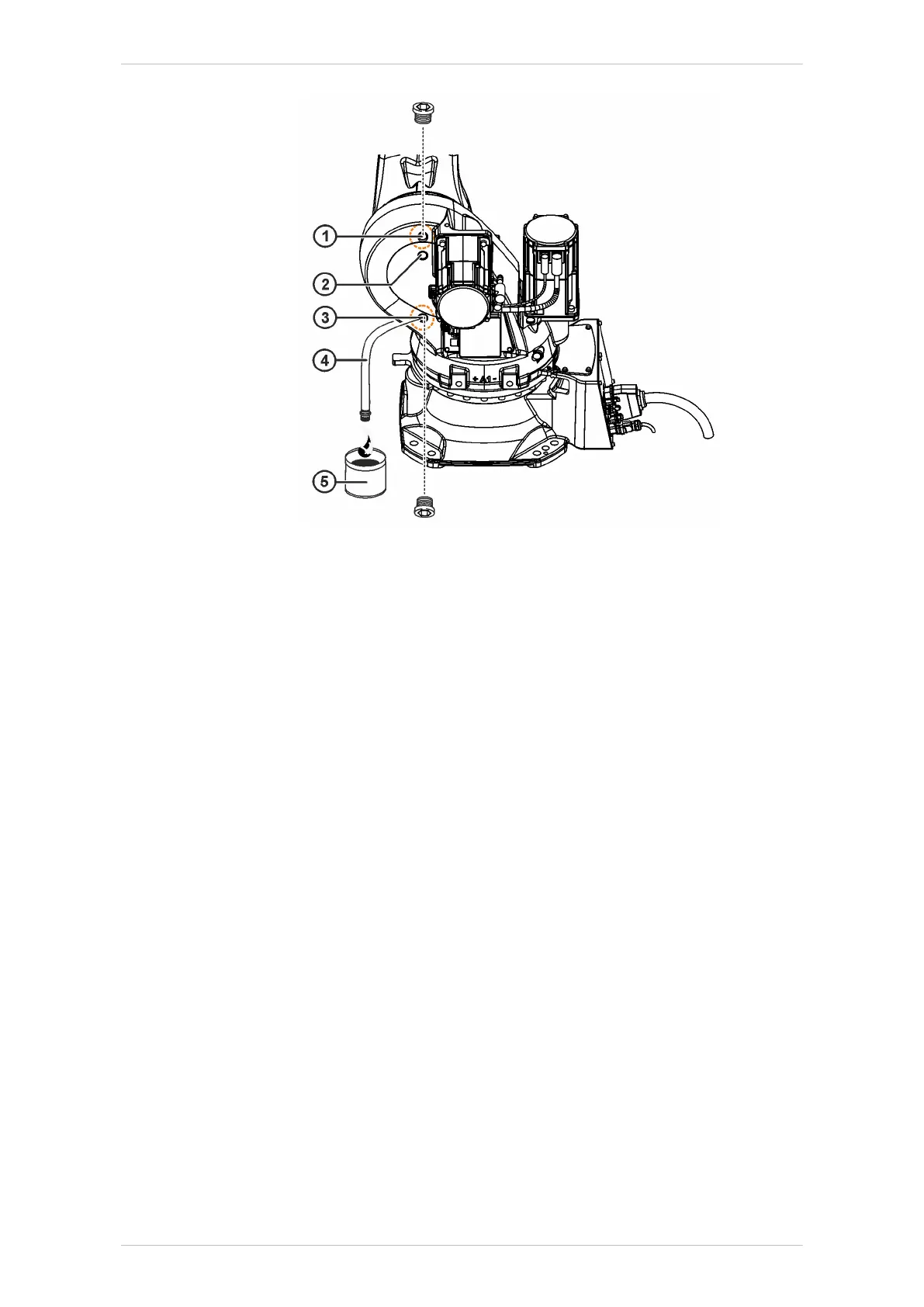

Fig. 8-6: Draining the gear oil from A2

1 M18x1.5 magnetic screw plug for venting

2 Inspection hole for floor installation

3 Oil drain hole with M18x1.5 magnetic screw plug

4 M18x1.5 oil drain tube

5 Collection receptacle

8.4.2 Filling gear unit A2 with gear oil

Procedure

1. Clean both M18x1.5 magnetic screw plugs and check the sealing ele-

ment; exchange magnetic screw plugs if damaged.

2. Connect the oil pump to the oil drain tube. The oil pump can also be

connected directly to the oil drain hole (>>> 8.4.2 "Filling gear unit A2

with gear oil" Page 202).

3. Unscrew the M18x1.5 magnetic screw plug from the inspection hole.

4. Fill the amount of oil from below up to the lower edge of the inspec-

tion hole using the oil pump.

5. Clean the M18x1.5 magnetic screw plug of the inspection hole and

check the sealing element; exchange if damaged.

Insert the M18x1.5 magnetic screw plug into the inspection hole and

tighten it; M

A

= 20 Nm.

6. Insert and tighten the upper M18x1.5 magnetic screw plug on the ro-

tating column; M

A

= 20 Nm.

7. Remove the oil pump from the oil drain hole or oil drain tube and

screw in M18x1.5 magnetic screw plug; M

A

= 20 Nm.

KR IONTEC

202/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Maintenance

Loading...

Loading...