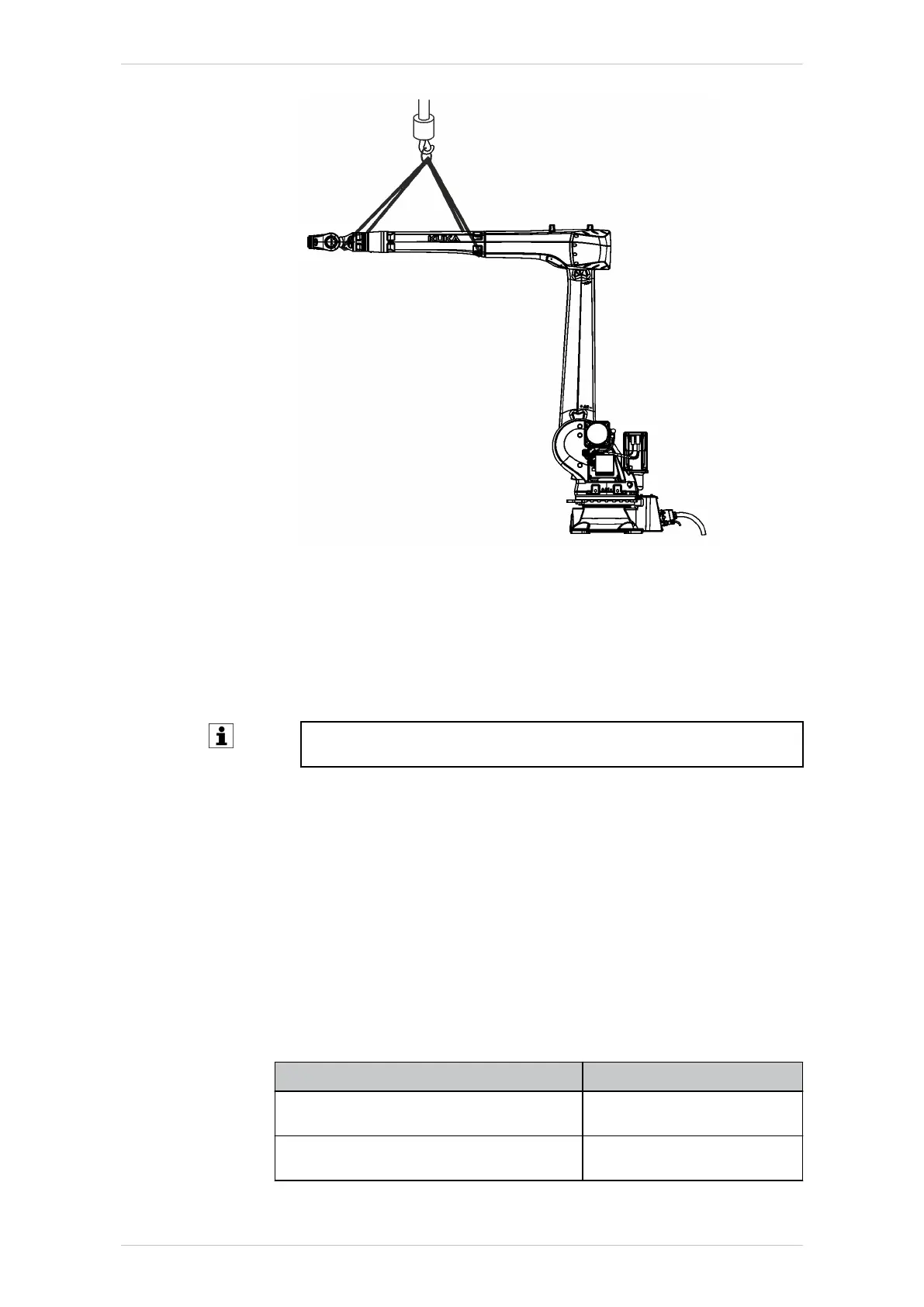

Fig. 9-44: Securing robot arm

9.5.3.12 Concluding work

The following concluding work must be carried out:

• Move A4, A5 and A6 of the robot and look out for irregularities.

• Carry out mastering of A4, A5 and A6.

Detailed information about mastering is contained in the operating

and programming instructions for end users or system integrators.

• Test the program in Manual Reduced Velocity mode (T1).

9.5.4 Exchanging the connecting shafts

Description

The following instructions describe the exchange of connecting shafts A4

and A5. The connecting shafts must always be exchanged as a pair. This

description applies to floor-mounted robots. If the robot is installed in an

inclined or suspended position, the procedure is to be applied analogously.

Equipment

The following equipment is required:

Designation Article number

Lifting tackle / rope sling with sufficient

load-bearing capacity

-

Crane with sufficient load-bearing capaci-

ty

-

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021 www.kuka.com | 285/344

Repair

Loading...

Loading...