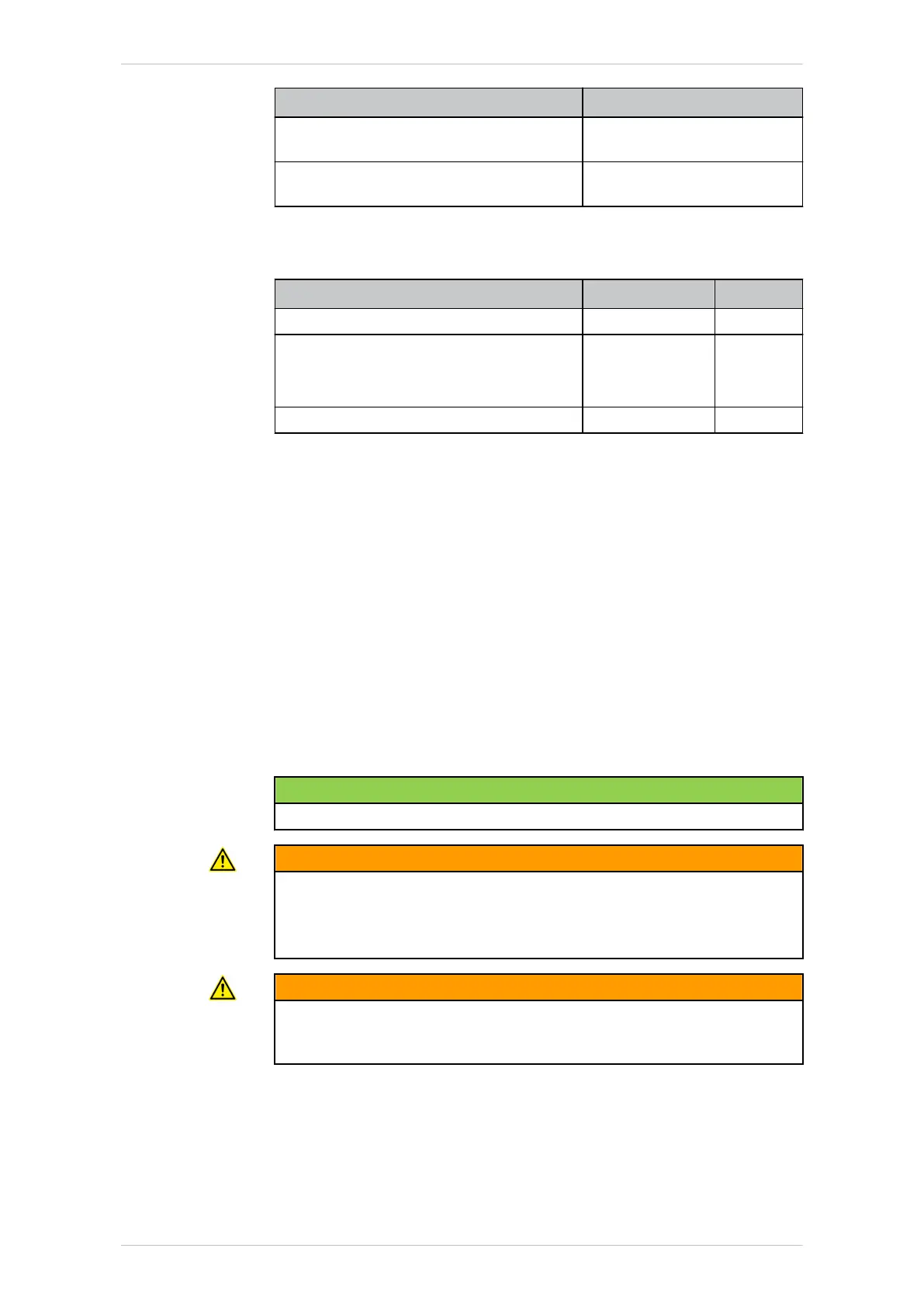

Designation Article number

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

5 Nm to 50 Nm

-

Material

The following material is required:

Designation Article number Quantity

Release device KR IONTEC 0000-348-346 1

or

12 mm combination wrench and TORX

key wrench TX25 and TX30

- 1 each

Slotted screwdriver 1

Tightening torques

The tightening torques can be found under: (>>> 12.1 "Tightening

torques" Page 335)

These are valid for screws and nuts where no other specifications are giv-

en.

Screws of strength class 10.9 and higher as well as screws with test cer-

tification may only be tightened once with the rated tightening torque.

When the screws are first slackened they must be replaced with new

ones.

Precondition

• The robot controller is switched off.

• The robot is freely accessible.

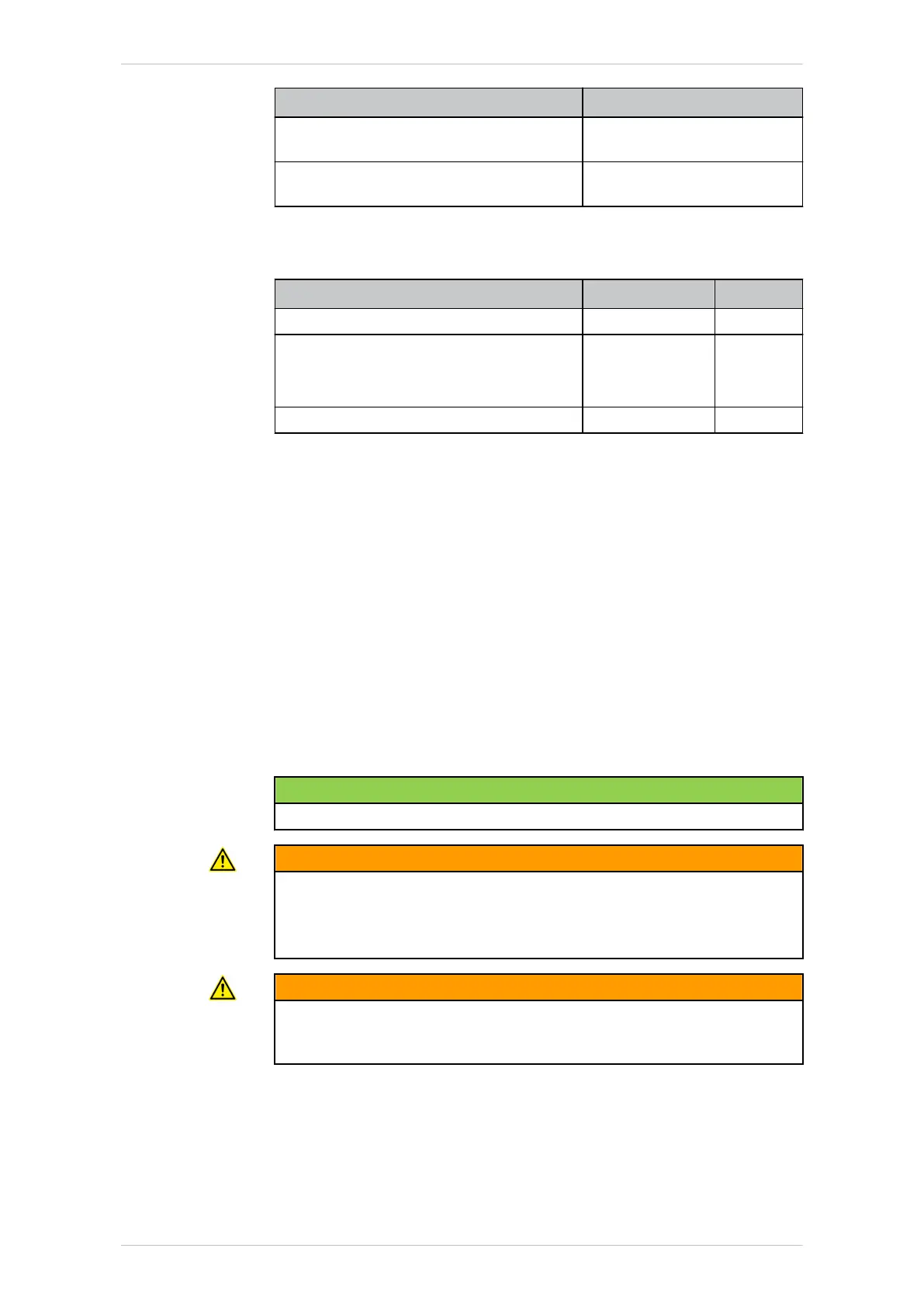

Work safety

SAFETY INSTRUCTION

The following procedure must be followed exactly!

WARNING

Danger to life and limb due to damaged motor brake

Moving an axis with the release device can damage the motor brake.

Death, severe injuries or damage to property may result.

• After using the release device, the motor must be exchanged.

WARNING

If a robot axis has been moved by the release device/rechargeable

screwdriver with torque bracket, all robot axes must be remastered. In-

juries or damage to property may otherwise result.

11.1.1.1 Installing the release device

Procedure

1. Position the clip plate on the rotating column, insert 2 M16x25-8.8-A2K

Allen screws and fasten in place. Increase the tightening torque to the

specified value in several stages.

KR IONTEC

320/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Options

Loading...

Loading...