9 Repair

Only maintenance and repair work described in this document may be

performed.

Work that exceeds this scope may only be carried out by personnel spe-

cially trained by KUKA. Information about KUKA College and its training

program can be found at www.kuka.com or can be obtained directly from

our subsidiaries.

In the case of support and repair services provided by KUKA, KUKA Serv-

ice must be informed in advance about potential contamination or haz-

ards.

Non-compliance nullifies warranty and liability claims.

9.1 Exchanging motor A1

Description

The following instructions describe the exchange of the motor. This de-

scription applies to floor-mounted robots. If the robot is installed in an in-

clined or suspended position, the procedure is to be applied analogously.

During removal of the motor, the robot can independently move about this

axis. Mechanical auxiliary equipment (e.g. support, crane) or a stable end

position (e.g. buffer) can be used to secure against motions.

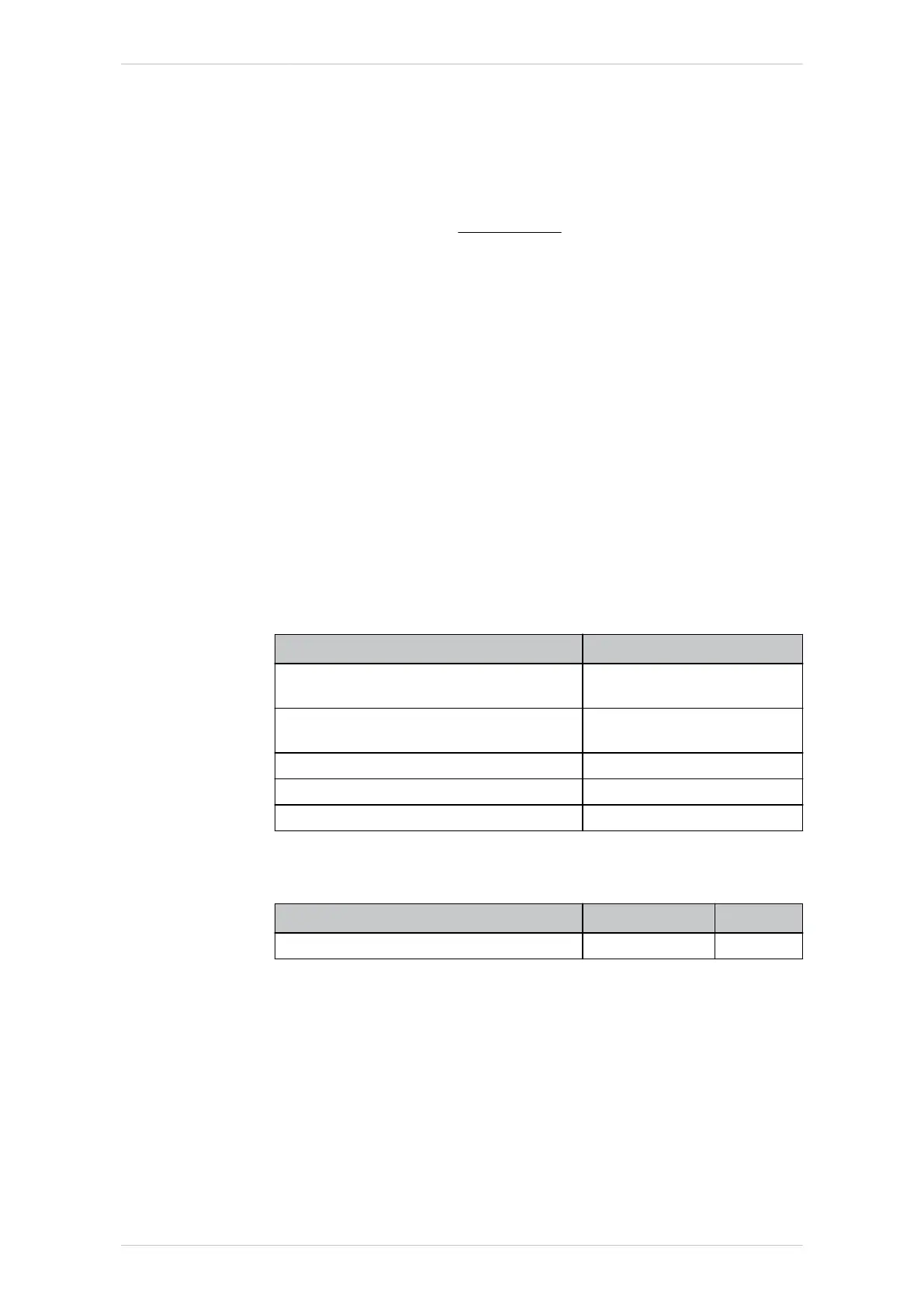

Equipment

The following equipment is required:

Designation Article number

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

min. 5 Nm to 50 Nm

-

Socket wrench set -

Brush -

SEMD/MEMD mastering set 0000-228-936

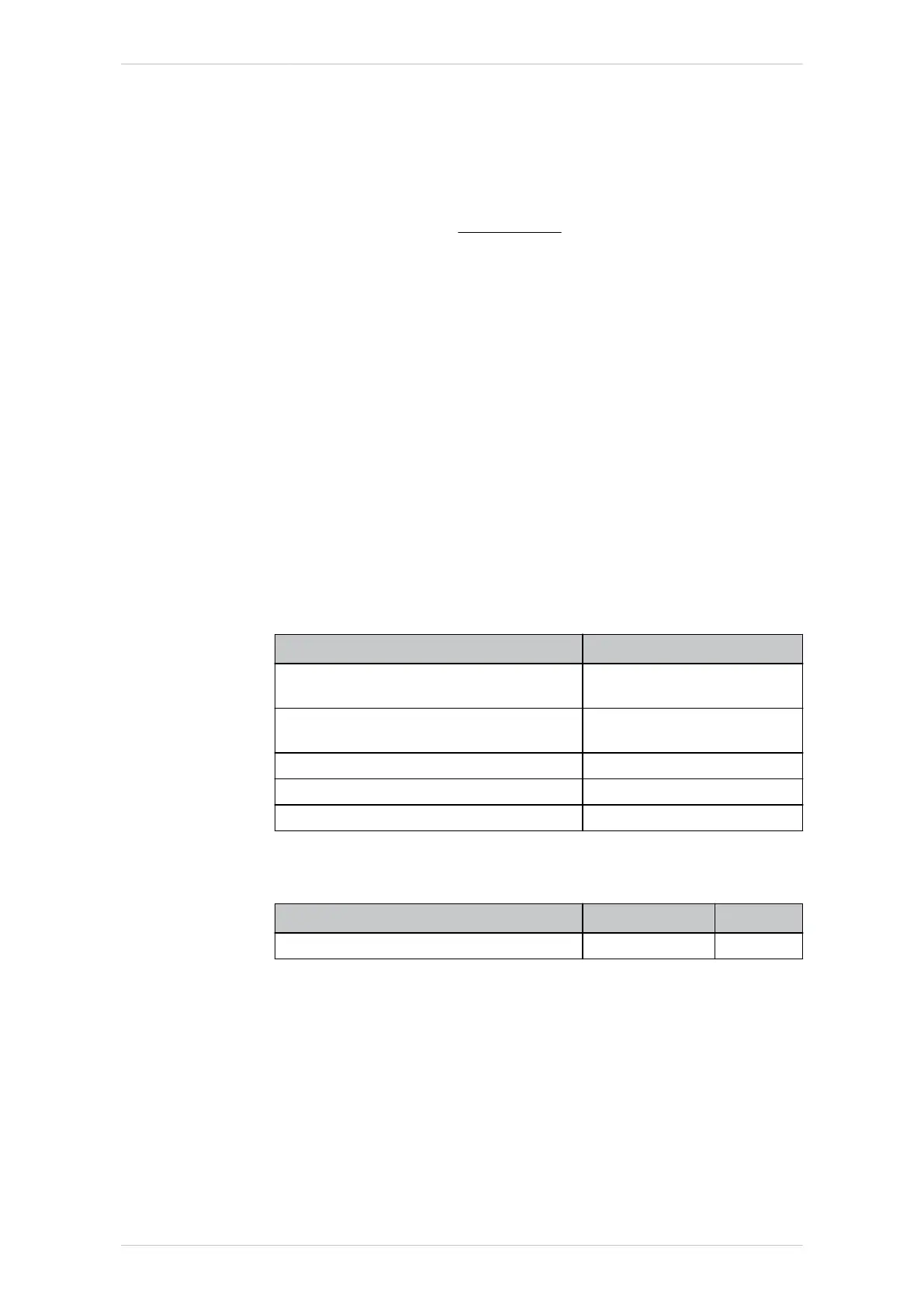

Material

The following material is required:

Designation Article number Quantity

SPP Motor 3,4 kW S0 ME 0000-352-524 1

Procurement of spare parts

Defective components must only be replaced with original spare parts

from KUKA Deutschland GmbH. Non-compliance nullifies warranty and lia-

bility claims.

A “Repair Card” is supplied with the exchange parts. This must be com-

pleted and returned to KUKA Deutschland GmbH together with the defec-

tive component in the following cases.

• Within the warranty period

• If, after consultation with KUKA Deutschland GmbH, an examination of

the defective component by KUKA is required.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021 www.kuka.com | 229/344

Repair

Loading...

Loading...