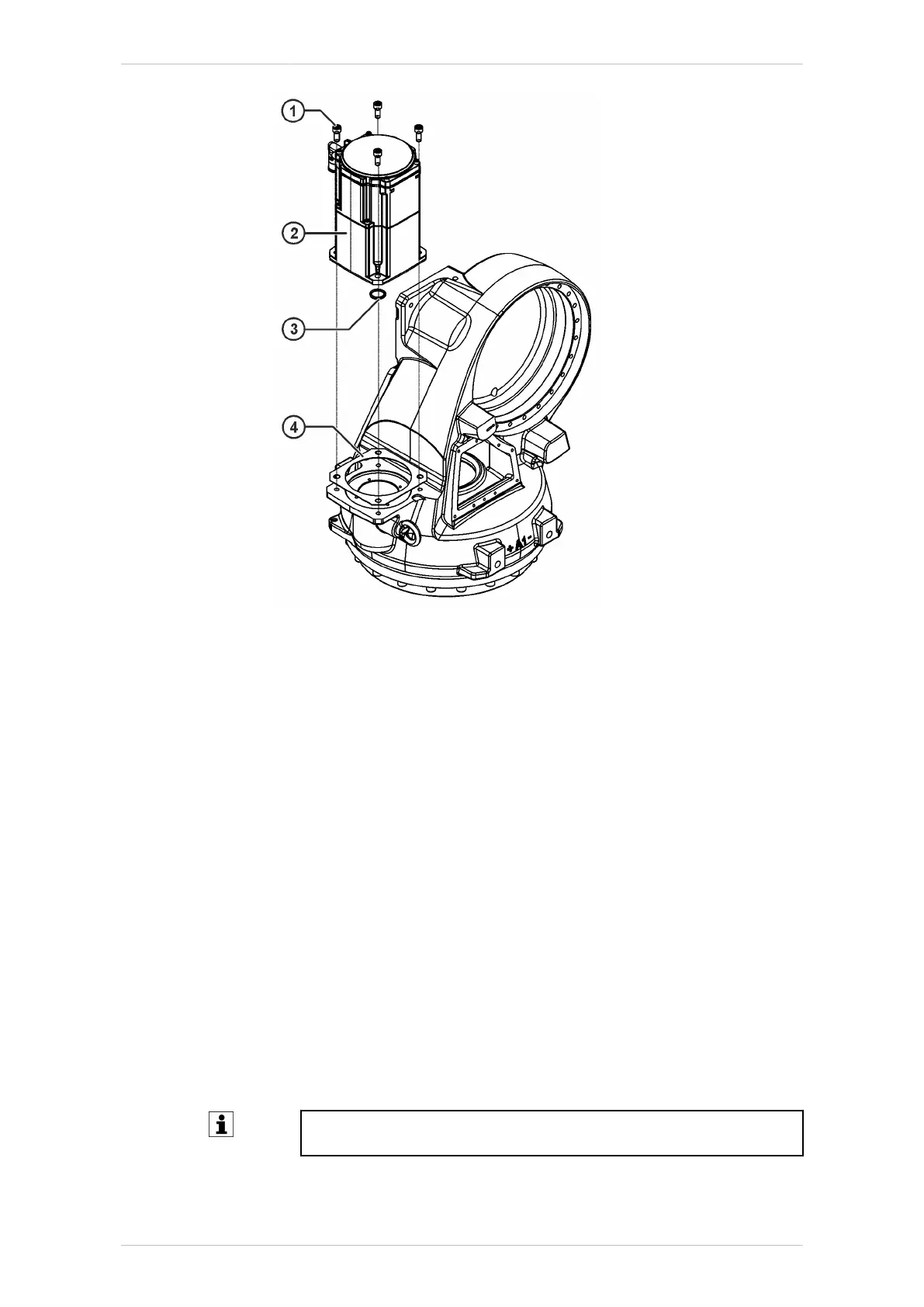

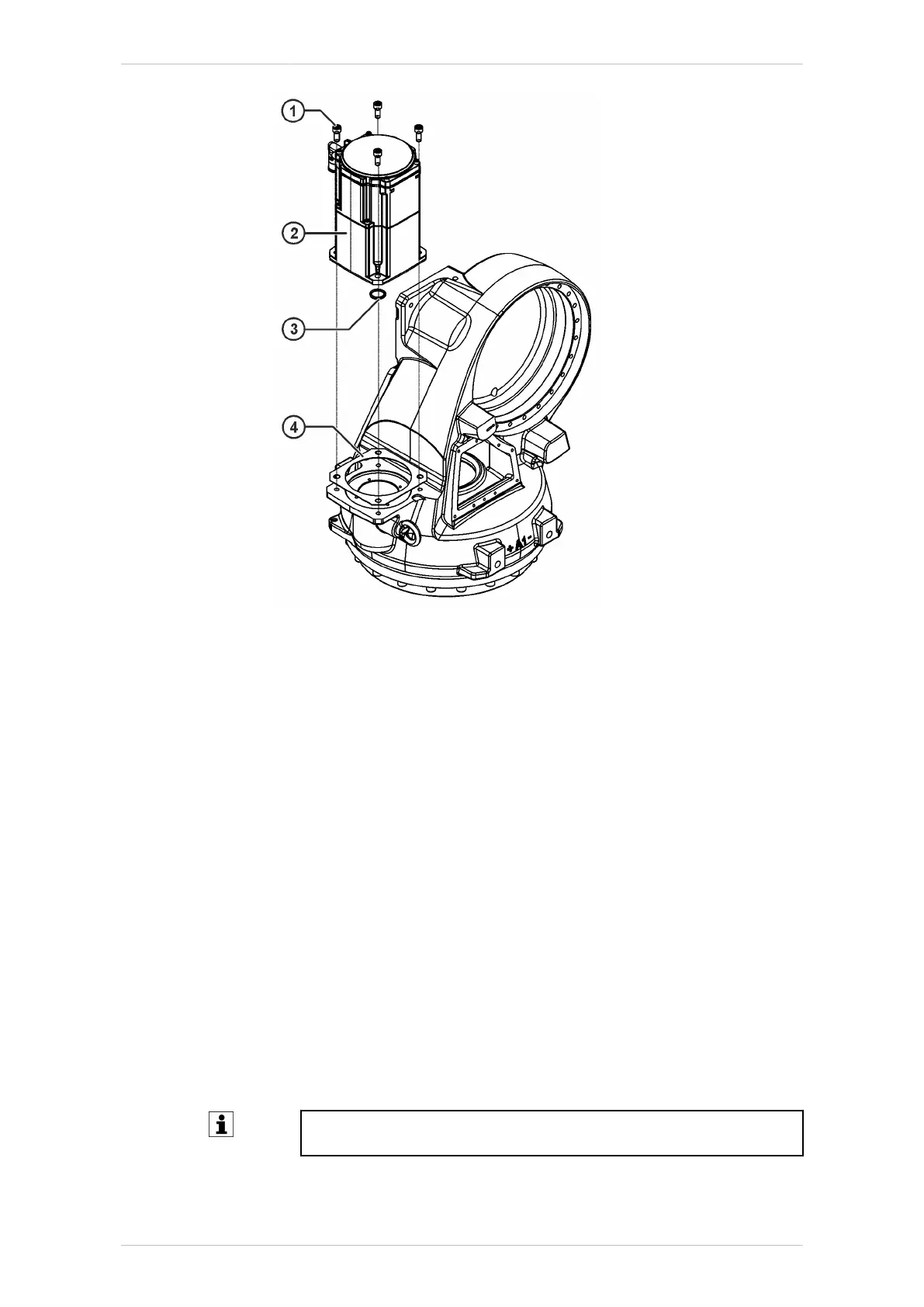

Fig. 9-13: Motor A1 Foundry

1 M10x25-8.8-A2K Allen screw (4x)

2 Motor A1

3 O-ring 23x4

4 Seal

9.4.1.2 Installing motor A1

Procedure

1. If a new motor is to be installed, remove any corrosion protection it

may have prior to installation (>>> 9.4.1.2 "Installing motor A1"

Page 249).

2. Clean the involute toothing of motor A1 and gear unit input shaft A1

before installation and apply a thin but continuous coat of Microlube

GL 261 grease.

3. Clean the mounting surface for motor A1.

4. Check the condition of the O-ring on the motor shaft; exchange if nec-

essary.

5. Position right-angle connectors XM1 and XP1 as shown.

6. Insert a seal.

7. Insert motor A1, taking care not to tilt it.

Insertion of motor can be facilitated by turning it gently about its ro-

tational axis.

8. Insert 4 M10x25-8.8-A2K Allen screws.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021 www.kuka.com | 249/344

Repair

Loading...

Loading...