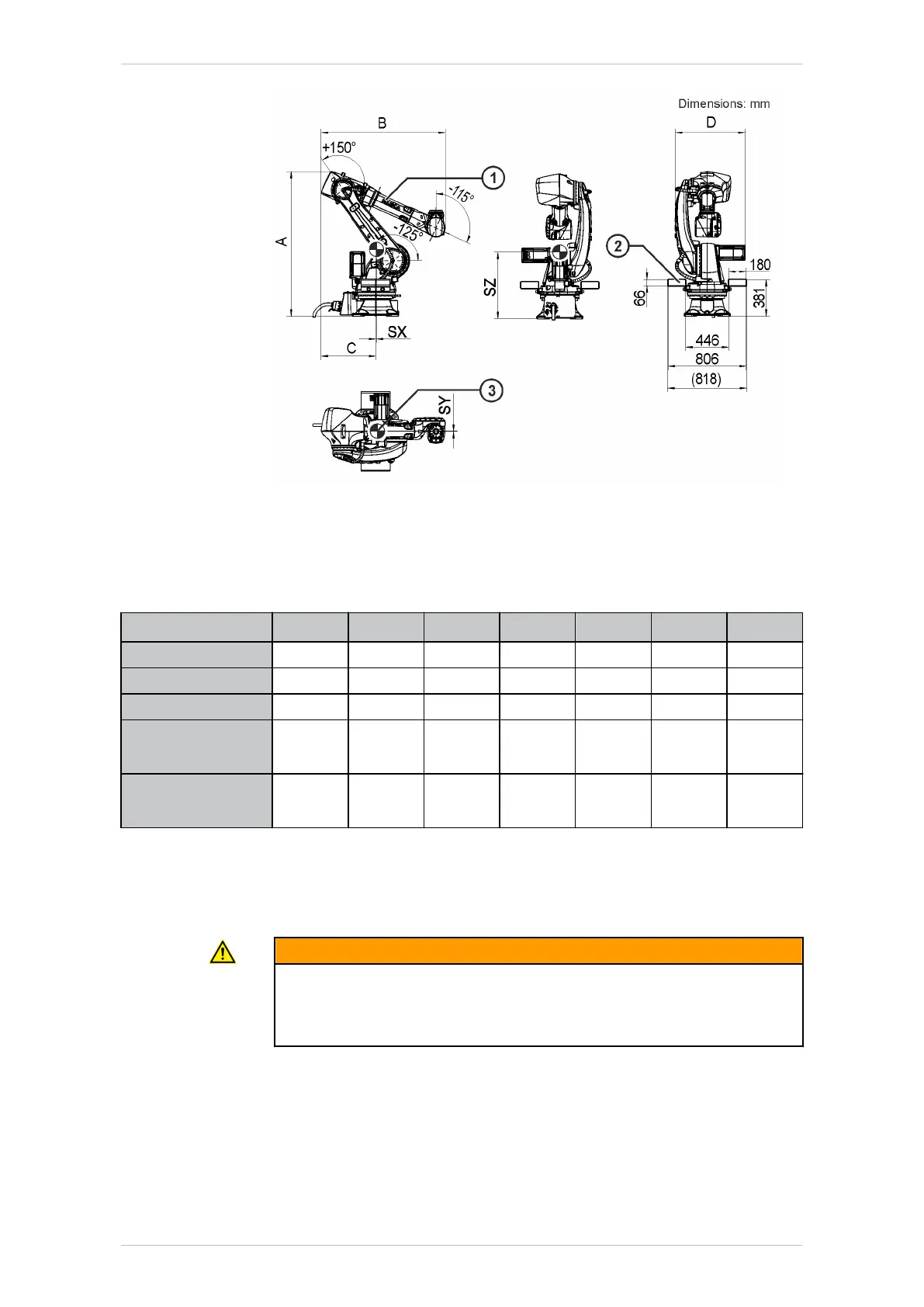

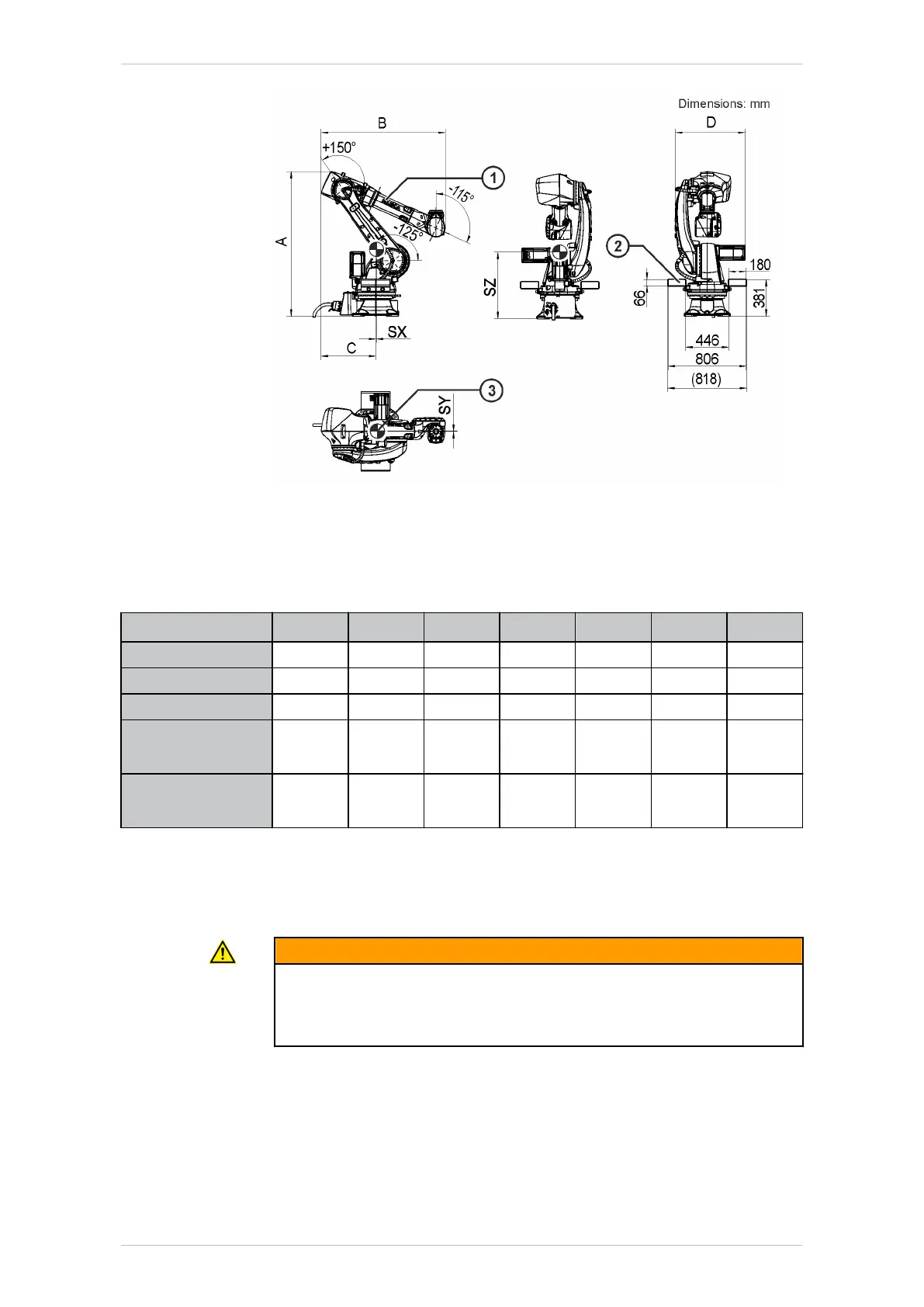

Fig. 6-2: Transport dimensions

1 Robot

2 Fork slots, optional

3 Center of gravity

Robot

A B C D SX SY SL

KR 20 R3100 1,829 1,764 791 744 -50 -14 803

KR 30 R2100 1,497 1,288 566 703 8 -1 687

KR 50 R2100 1,497 1,288 566 703 8 -1 687

KR 50 R2500

KR 50 R2500 F

1,824 1,288 790 744 -84 -11 799

KR 70 R2100

KR 70 R2100 F

1,497 1,288 566 723 8 3 687

Transportation

The robot can be transported by fork lift truck or using lifting tackle. The

ceiling-mounted robot in its installation position can only be transported

outside the transport frame using a fork lift truck.

WARNING

Use of unsuitable handling equipment may result in damage to the robot

or injury to persons. Only use authorized handling equipment with a suf-

ficient load-bearing capacity. Only transport the robot in the manner

specified here.

Transportation by fork lift truck

For transportation by fork lift truck (>>> Fig. 6-3), fork slots are mounted

on the side of the rotating column. The robot can be picked up by the fork

lift truck from the front or rear. The robot must not be damaged when in-

serting the fork into the fork slot. The fork lift truck must have a minimum

payload capacity of 2.0 t and an adequate fork length.

KR IONTEC

168/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Transportation

Loading...

Loading...