Equipment

The following equipment is required:

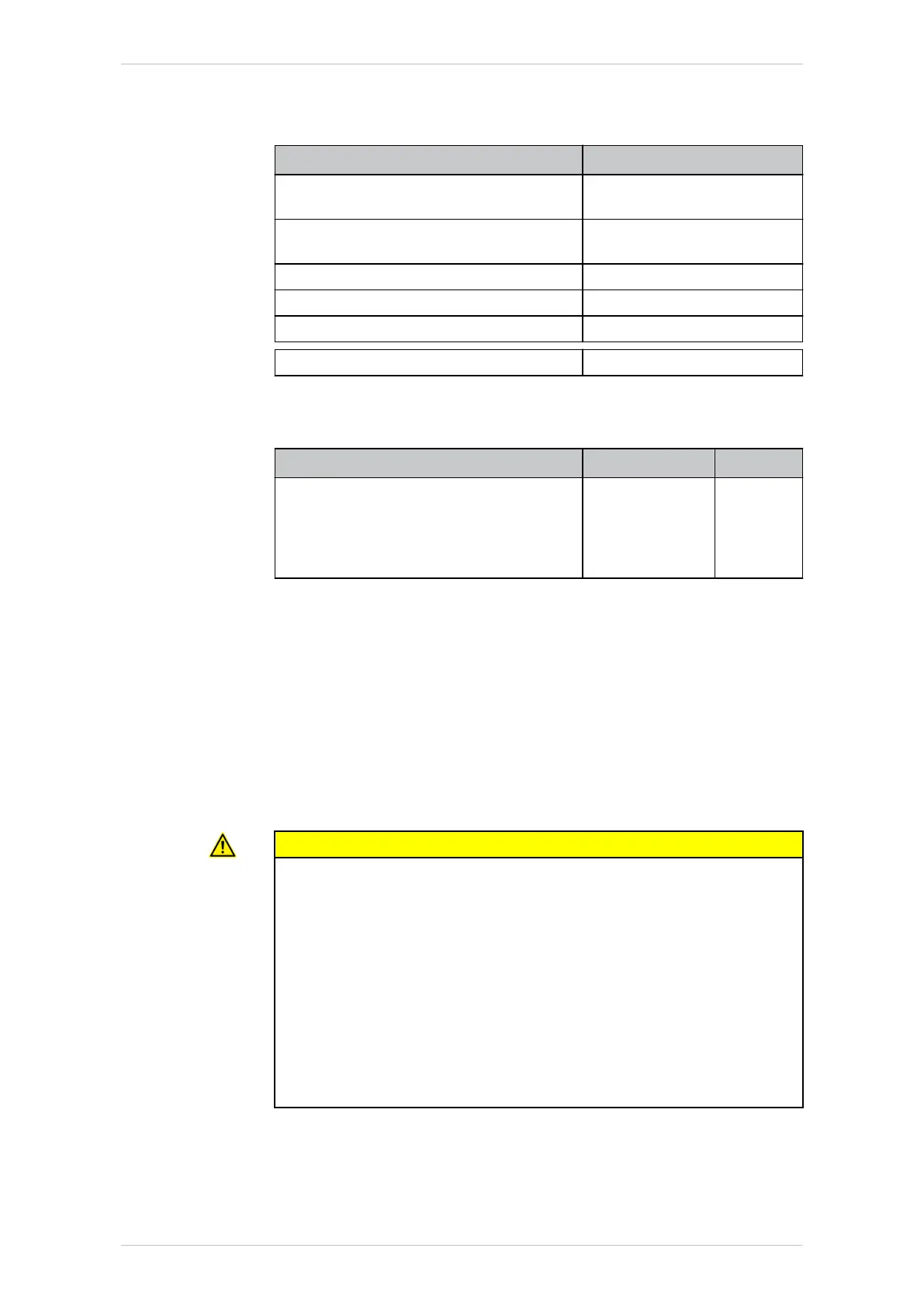

Designation Article number

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

min. 2 Nm to 30 Nm

-

Socket wrench set -

Collection receptacle -

Funnel -

Oil drain tube - M10x1 0000-265-663

Material

The following material is required:

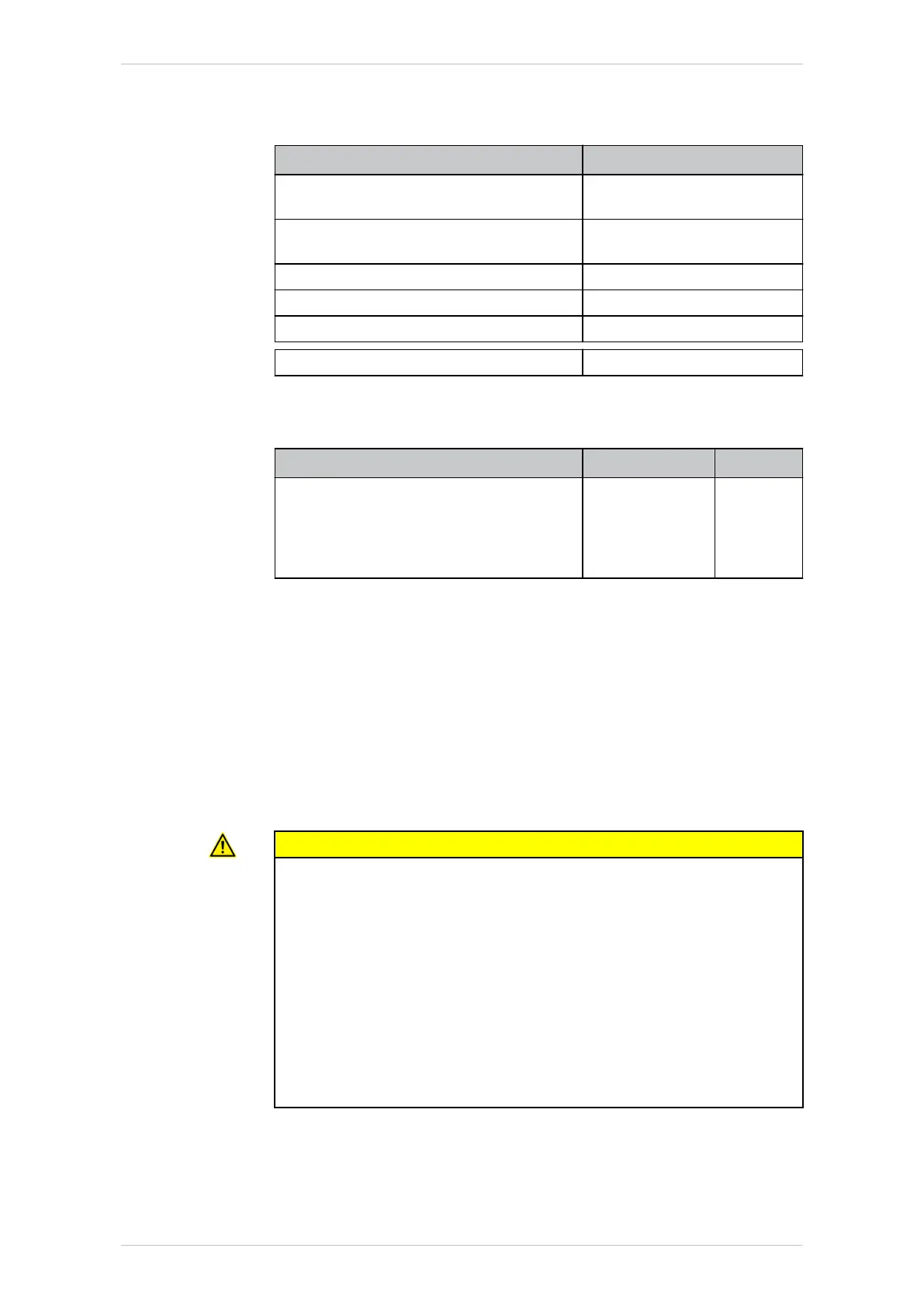

Designation Article number Quantity

Optigear Synt. ALR 150 (>>> 12.2 "Aux-

iliary and oper-

ating materials

used"

Page 336)

Initial fill-

ing quan-

tity: 0.23 l

Tightening torques

The tightening torques can be found under: (>>> 12.1 "Tightening

torques" Page 335)

These are valid for screws and nuts where no other specifications are giv-

en.

Screws of strength class 10.9 and higher as well as screws with test cer-

tification may only be tightened once with the rated tightening torque.

When the screws are first slackened they must be replaced with new

ones.

Refilling quantity

CAUTION

The quantity of oil drained depends on the draining time and the oil

temperature. The refilling quantity is the quantity of oil that was drained

from the gear unit at the correct operating temperature and with the cor-

rect draining time. This oil quantity must be determined. Only this quan-

tity of oil may be used when refilling.

If less than 70 % of the specified oil quantity flows out, flush the gear

unit with the determined quantity of drained oil once, then pour in the

amount of oil that was drained. If less than 50% of the specified oil

quantity flows out (e.g. inclined installation), the flushing operation must

be repeated twice. During the flushing procedure, move the axis at jog

velocity throughout the entire axis range.

The oil quantities specified in the table correspond to the oil quantities

in the gear unit at first filling.

Precondition

• The gear unit is at operating temperature.

• The arm and in-line wrist are in horizontal position.

KR IONTEC

224/344 | www.kuka.com MA KR IONTEC V4 | Issued: 11.05.2021

Maintenance

Loading...

Loading...