Equipment

The following equipment is required:

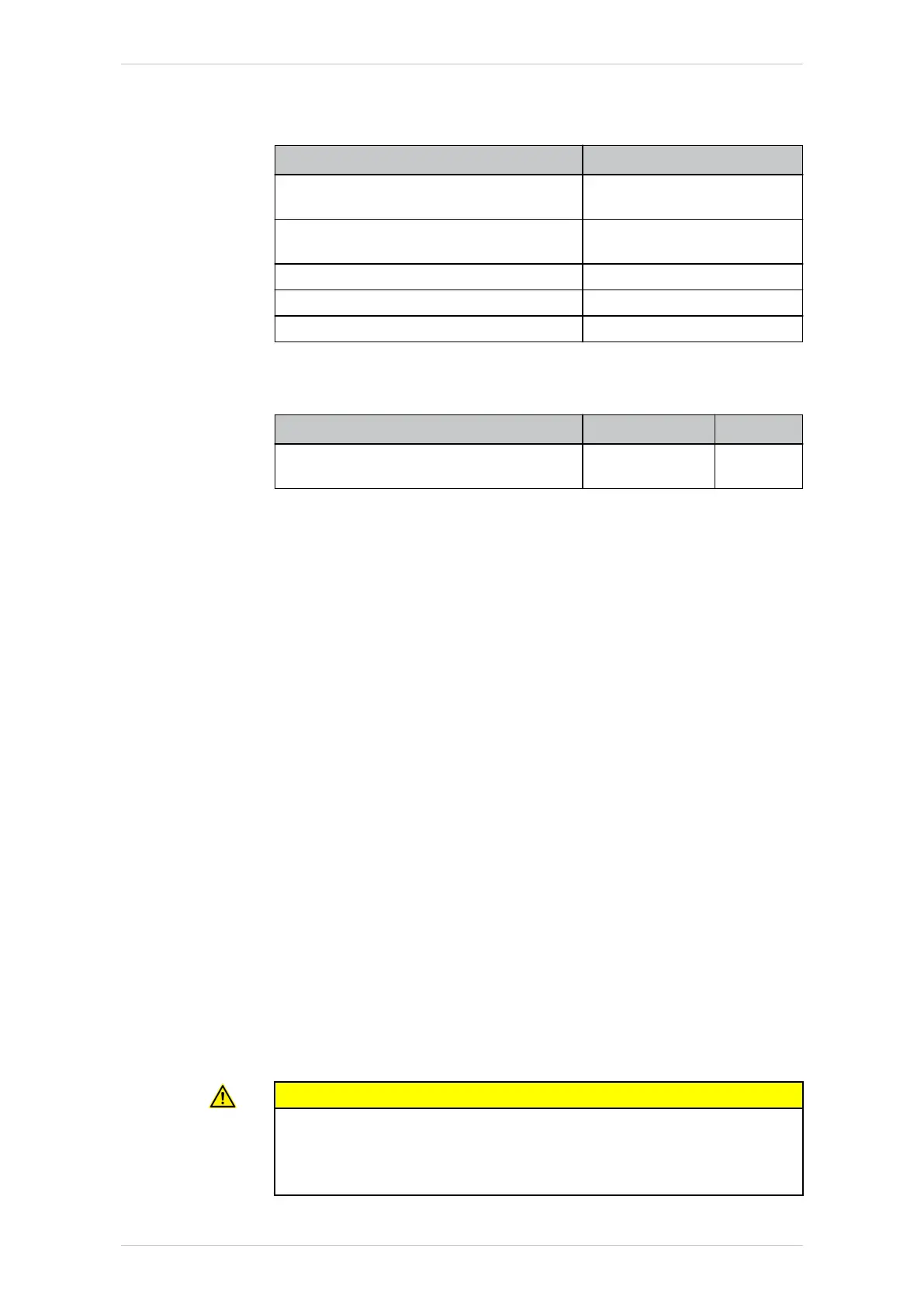

Designation Article number

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

min. 5 Nm to 50 Nm

-

Socket wrench set -

Brush -

SEMD/MEMD mastering set 0000-228-936

Material

The following material is required:

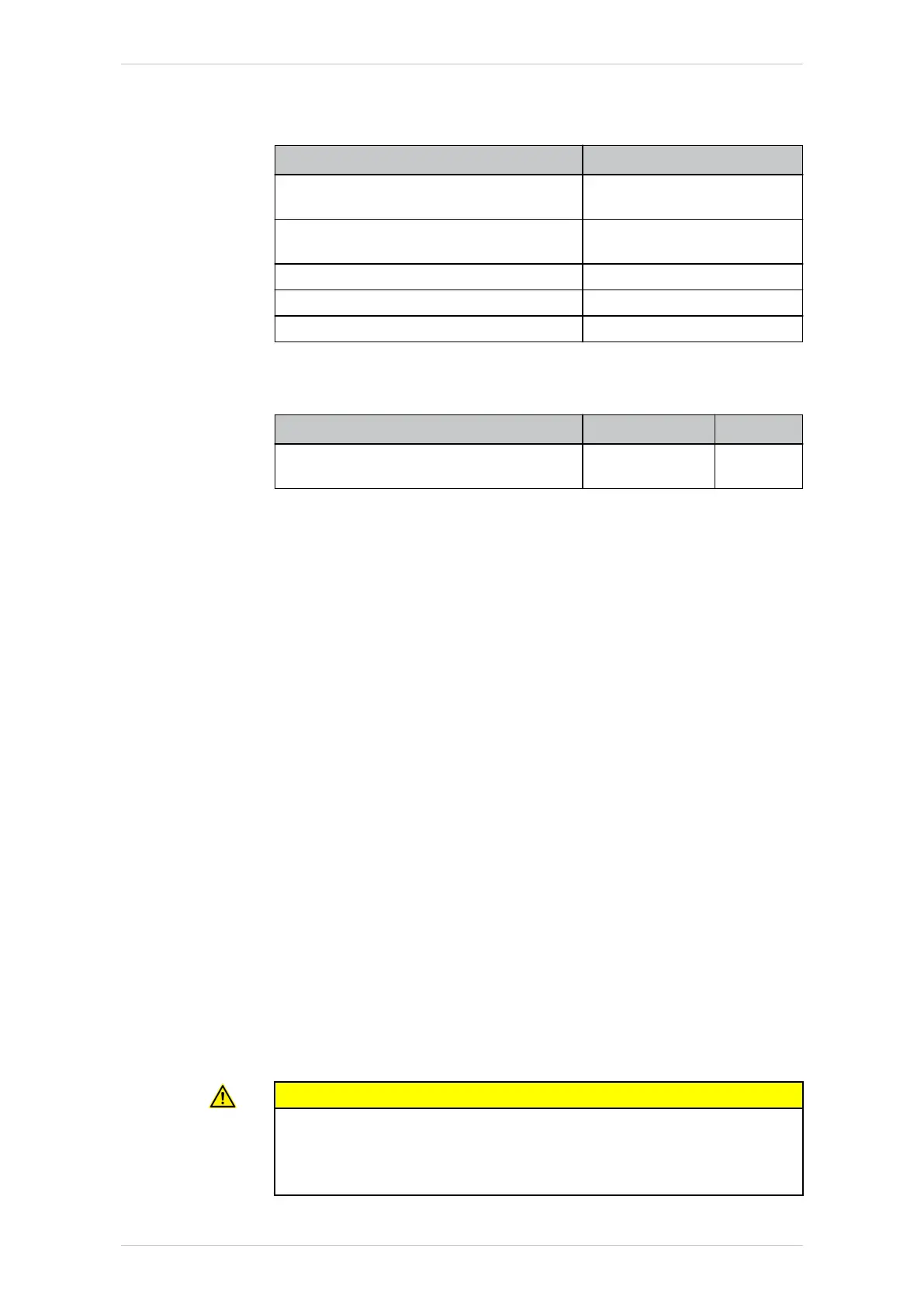

Designation Article number Quantity

SPP motor 3.4kW S0 ME Foundry (w/o

adh.)

0000-387-992 1

Procurement of spare parts

Defective components must only be replaced with original spare parts

from KUKA Deutschland GmbH. Non-compliance nullifies warranty and lia-

bility claims.

A “Repair Card” is supplied with the exchange parts. This must be com-

pleted and returned to KUKA Deutschland GmbH together with the defec-

tive component in the following cases.

• Within the warranty period

• If, after consultation with KUKA Deutschland GmbH, an examination of

the defective component by KUKA is required.

Tightening torques

The tightening torques can be found under: (>>> 12.1 "Tightening

torques" Page 335)

These are valid for screws and nuts where no other specifications are giv-

en.

Screws of strength class 10.9 and higher as well as screws with test cer-

tification may only be tightened once with the rated tightening torque.

When the screws are first slackened they must be replaced with new

ones.

Precondition

• The robot is secured by means of an EMERGENCY STOP device. It

must be ensured that the robot cannot be switched on by unauthor-

ized persons.

Work safety

CAUTION

Risk of burns on hot surfaces

High motor surface temperatures immediately after the robot has stop-

ped operating can lead to burns. Injuries may result.

• Protective gloves must be worn.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021 www.kuka.com | 247/344

Repair

Loading...

Loading...