MaintenanceInstructions

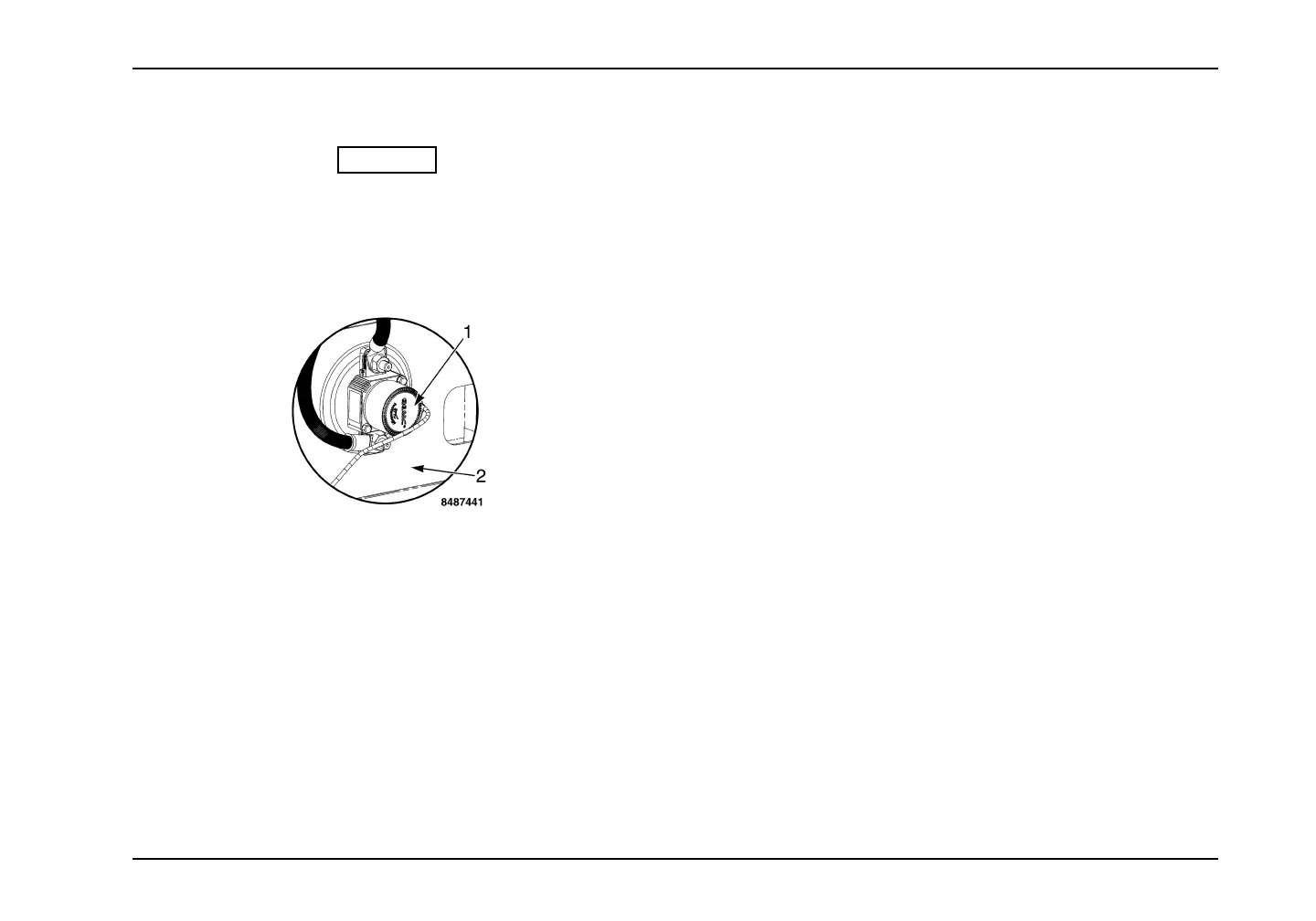

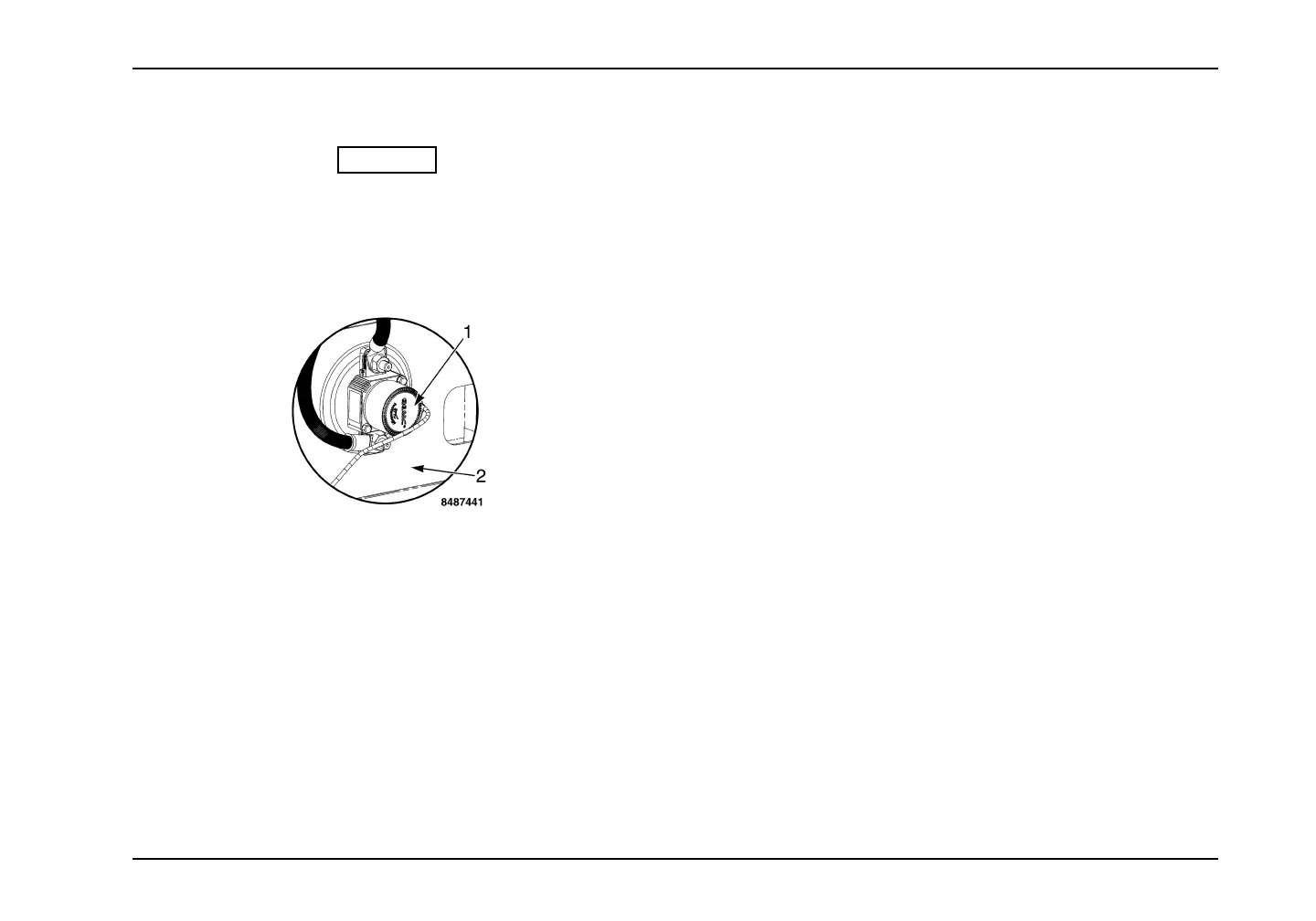

HighCurrentRelay

CAUTION

Topreventpropertydamage,whenservicing

theisolationbattery,besurethatallcables

areconnectedcorrectlytopreventdamage

tothehighcurrentrelayandotherelectrical

components.

1.HighCurrentRelay

2.BatteryBox(Back)

Themainvehicle’sbatteryboxisequippedwithahighcurrent

relaytoisolateonebatteryduringtheautostart/stopcrank

operationandtostabilizepowertoelectricalsystemcontrollers.

ElectricalChargingandStartingSystemTest

AteveryPreventiveMaintenance(PM),fullychargethe

batteriesusinganautomaticoatcharger.Then,havea

qualiedtechnicianperformanelectricalsystemtestusingan

International

®

ElectronicSystemT ester(MidtronicsinTELLECT

EXPHDExpandableElectricalDiagnosticsPlatformavailable

throughyourlocalInternationaldealer)tocatchelectricalsystem

problemsbeforetheycausefurtherdamagetothebatteriesand

preventastrandedvehicle.Thetestwillcheckforalternator

amperageoutput,startercurrentdraw,andbatteryamperage

capacity.Thistypeoftestingwilldetectweaknessesthatmay

notyetbeapparentduringnormaldailyoperations.

TerminalInspection-Cleaning-CorrosionProtection

Periodicallyinspectelectricalconnectorsontheengine,battery,

andframeforcorrosionandtightness.Inspectexposedcables

forfrayingorsignsofabrasion.Exposedterminals,such

ascrankingmotor,alternator,andfeed-throughstudsshould

becleanedandrecoatedwithadielectricgrease,suchas

Fleetrite

®

472141–C1orequivalentpasteorsprayprotectant.

Theinspection/cleaning/corrosionprotectionshouldinclude

feed-throughconnections,powerandgroundcableconnections

forbatteries,engines,andthestarterstud.

Connectorsthataremoresubjecttocorrosionmaybe

disassembledandsprayedinternallywithalightcoatingof

dielectricgrease.Usegreasesparingly,astoomuchgreasewill

notallowairtoescapefromtheconnectionandthiscompressed

airwillpushoutthesealsintheelectricalconnectors.

217

Loading...

Loading...