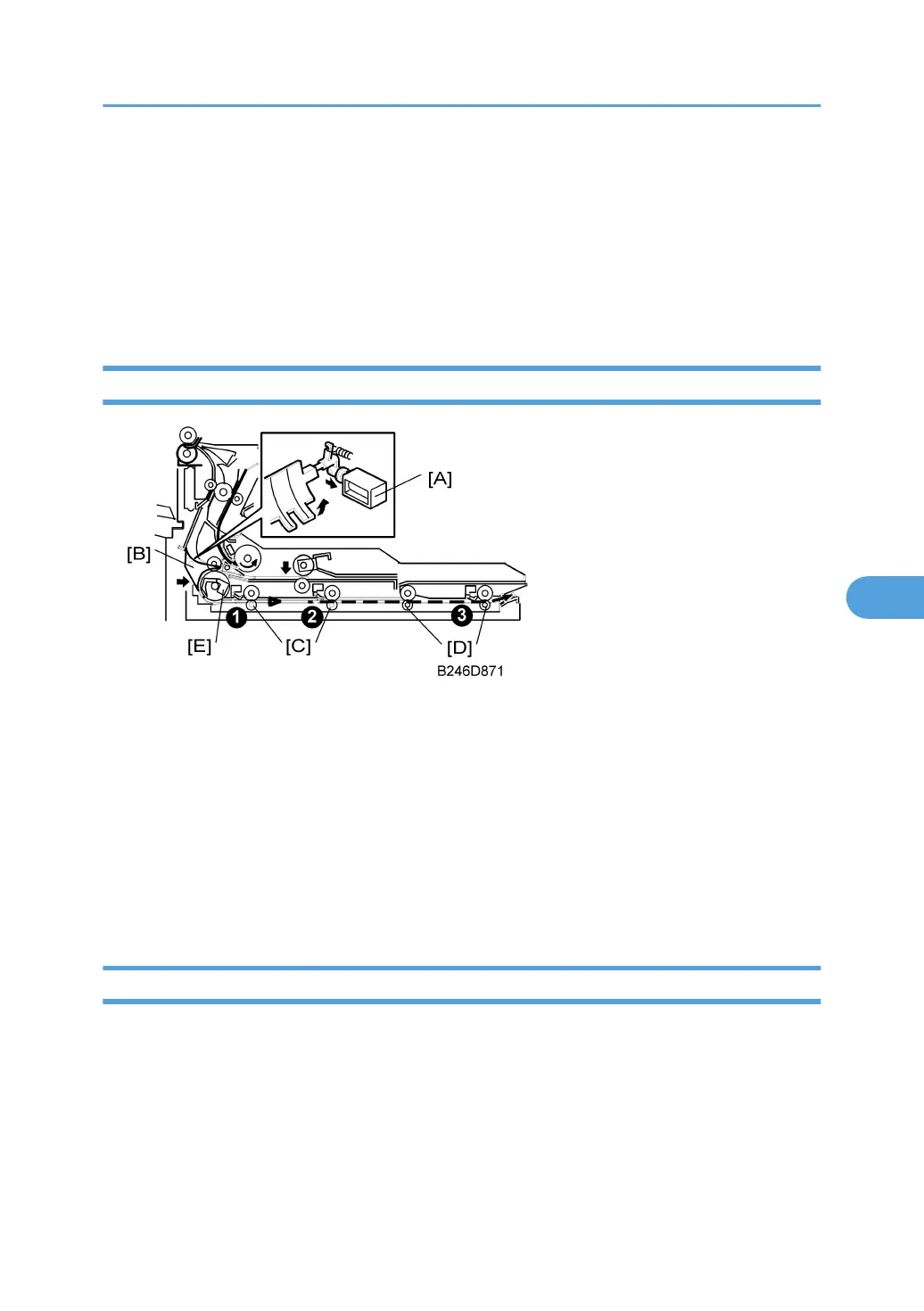

After jogging, each page is fed back as follows:

• Solenoid [A] pushes down roller [B].

• Roller [B] contacts roller [C], catching the paper between the two rollers.

• Roller [C] always turns counter-clockwise, and feeds the paper [D] backwards to roller [E].

When the leading edge of the paper, now caught by roller [E], passes duplex inverter sensor [F], solenoid

[A] switches off and roller [B] returns to its home position.

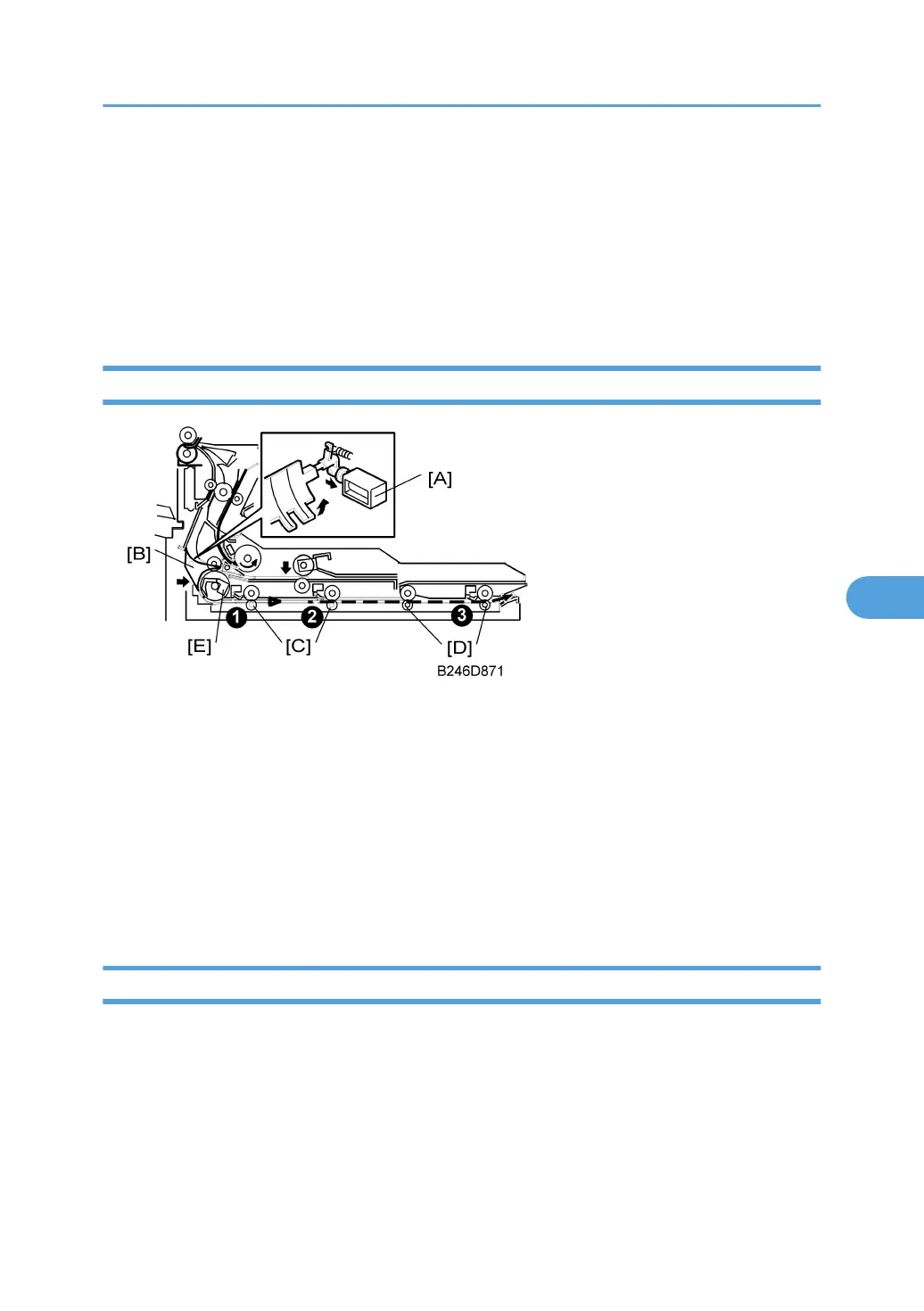

Duplex Tray Feed

After inversion:

• If duplex mode is not selected, the duplex junction gate solenoid [A] does not switch on to open the

duplex junction gate [B]. The paper goes to the output tray or finisher face down.

• If duplex mode is selected, after the paper leaves the inverter, the solenoid [A] switches on and opens

the junction gate [B]. The paper goes down to the duplex tray.

For details about how the transport rollers [C] and [D] and the inverter sensor [E] operate to control duplex

feed, refer to the sections above.

Duplex transport sensors ¶, ·, ¸ detect jams in the paper path.

Duplex Interleave Feed

The number of sheets that can be processed at a time depends on the size of the paper.

The table below shows the order of page processing for a 14-page job. Odd numbers are the front sides

of the pages, even numbers are the back sides. A number in a black circle means printing on the second

side of a sheet of paper (black 1 means printing on side 2 of sheet 1).

Duplex Unit

515

Loading...

Loading...