4 Operation

Handling the battery

Terminals and cable shoes must be clean,

lightly coated with battery grease and screwed

on tightly.

– Neutralise any spilt battery acid immedi-

ately.

– For information on handling ba

ttery acid,

see the "Battery acid" secti

on in the chapter

entitled "Safety regulatio

ns for handling

consumables".

6210_600-001

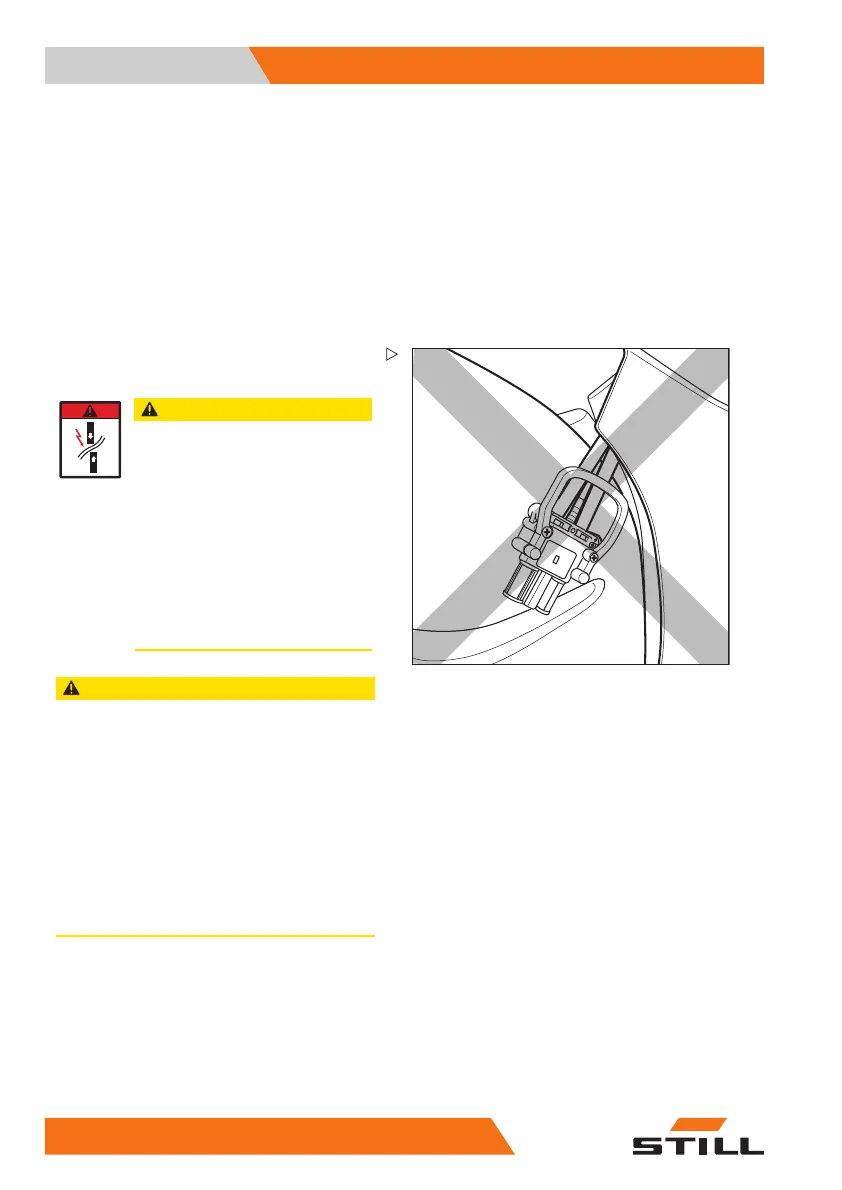

Category-3 battery male connector

Damage to cables and batte

ry male

connectors

CAUTION

There is a risk of short circuit if the

cables are damaged.

Do not crush the battery cables when

closing the battery door.

– Check the battery cables for

damage.

– When removing and reinstalling

the battery, ensure that the battery

cables are not damaged.

– Ensure that the battery cables

do not come into contact with the

battery door.

CAUTION

Potential for damage to the battery male connector!

If the battery male connector is disconnected or

connected while the truck is switched on or while

the battery charger is under load, an electrical arc

or a transition spark will be produced at the battery

male connector. This can lead to erosion at the

contacts and can considerably shorten the service

life of the contacts.

– Switch off the truck or the battery charger before

disconnecting or connecting the battery male

connector.

– Do not disconnect the battery male connector

while under load, except in an emergency.

Ventilation gap

The ve

ntilation gaps between the battery door

and th

e chassis are used for forced-air cooling

of the

battery compartment.

– Do not plug the ventilation gaps.

314

56368011531 EN - 06/2019 - 02

Loading...

Loading...