Maintenance 5

Preserving operational readiness

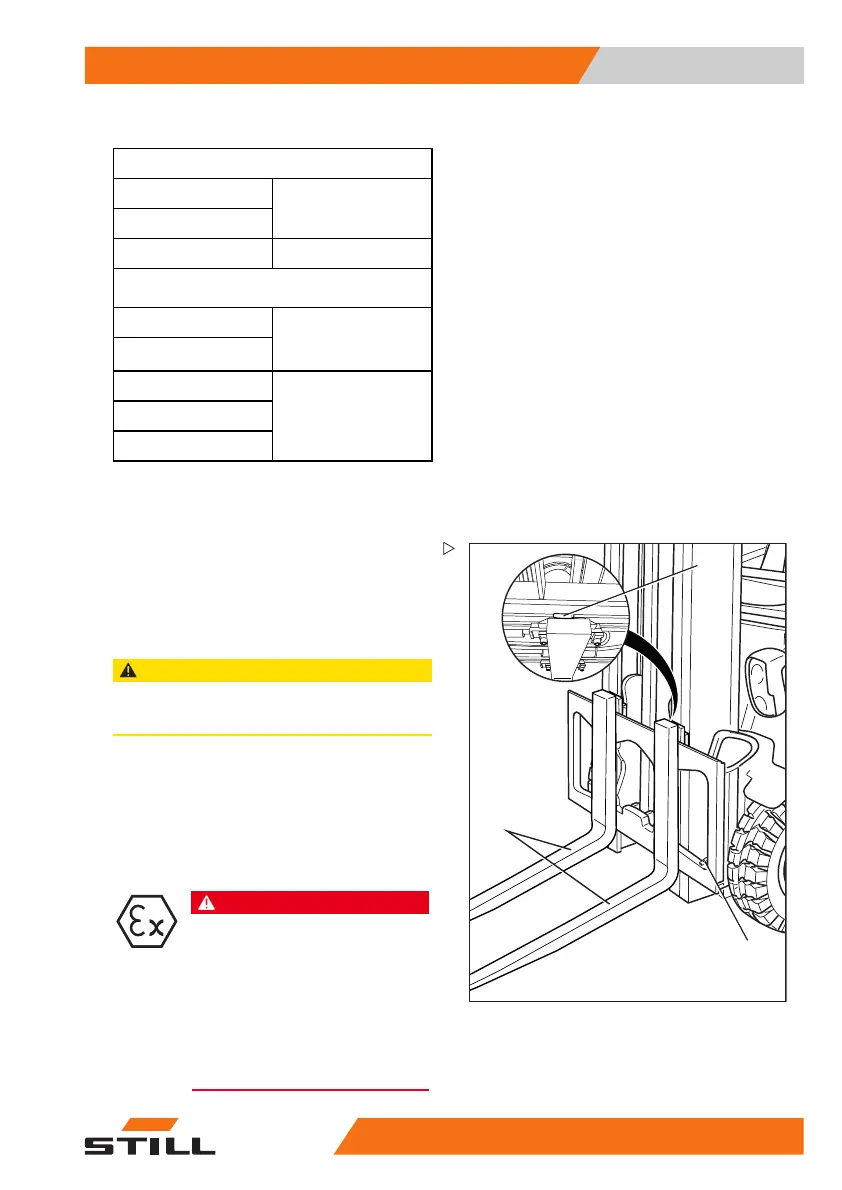

Thickness and material of the cladding

Thickness in new condition

Top

Side

2mm

Bottom 4 mm

Material depending on the category of the

truck

IIA

IIB

Stainless steel to

AISI 316L

IIB + H

2

IIB + C

2

H

2

IIB + H

2

+C

2

H

2

Copper materials

– If you have any ques

tions about this please

contact your autho

rised service centre.

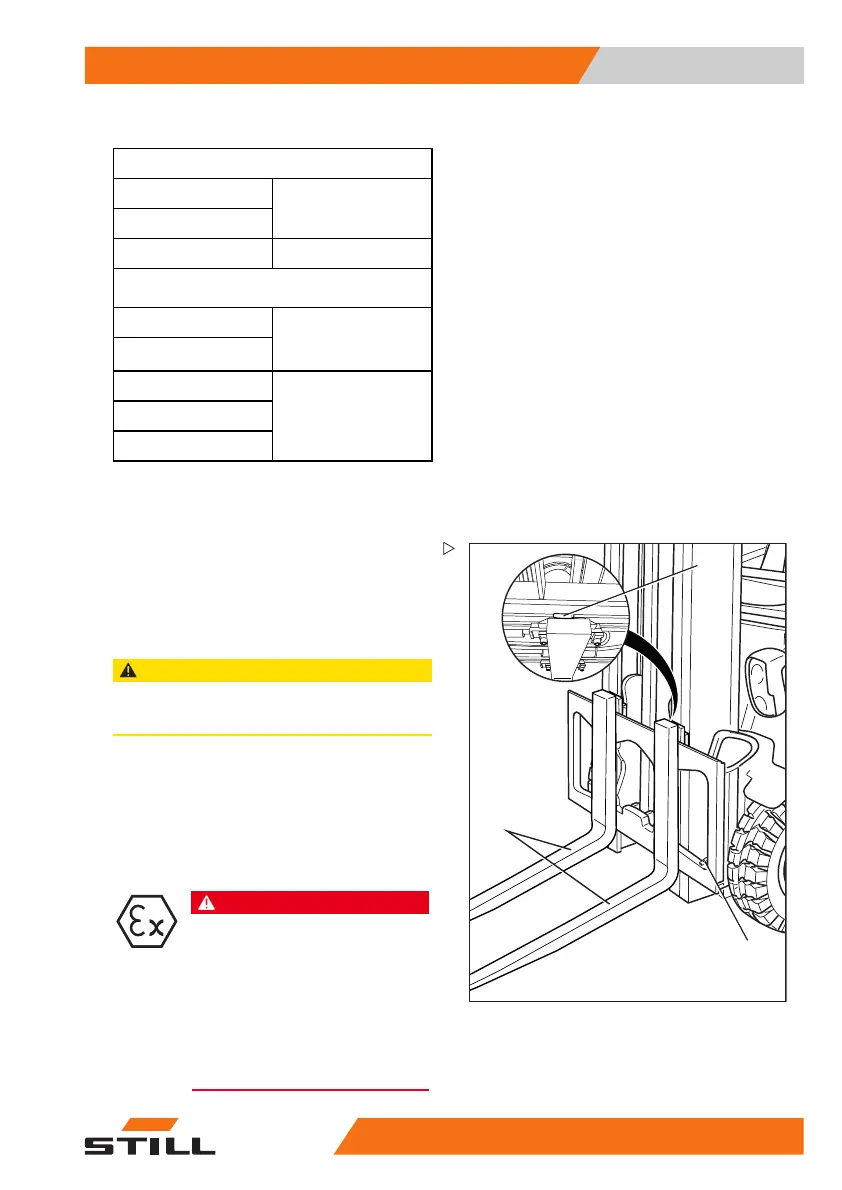

2

1

3

Checking the con

dition and correct

operation of th

elatch

– Check the fork arms (1) for any visible

deformation. Wear must not amount to

more than 10% of the original thickness.

CAUTION

Risk of component damage!

Always replace worn fork arms in pairs.

– Check that the fork latch (3) is functioning

correctly.

– Make sure that the locking screw (2) is

present and cannot fall out.

Repairing the fork arms

DANGER

Risk of explosion due to improper

repair!

Damaged or worn cladding may be

only repaired by the manufacturer or

by a specialist welder.

All straightening work (hot and cold)

on deformed fork arms is forbidden.

– Contact the authorised service

centre.

563

68011531 EN - 06/2019 - 02 387

Loading...

Loading...