PROCEDURE

1 Make sure that the turning gear is engaged.

2 Operate the turning gear to get the piston of the first cylinder to the TDC position.

3 On the local control panel, get the cylinder lubrication page.

4 Select the applicable cylinder number.

5 If necessary, change the number of lube pulses (in the range 0 to 200).

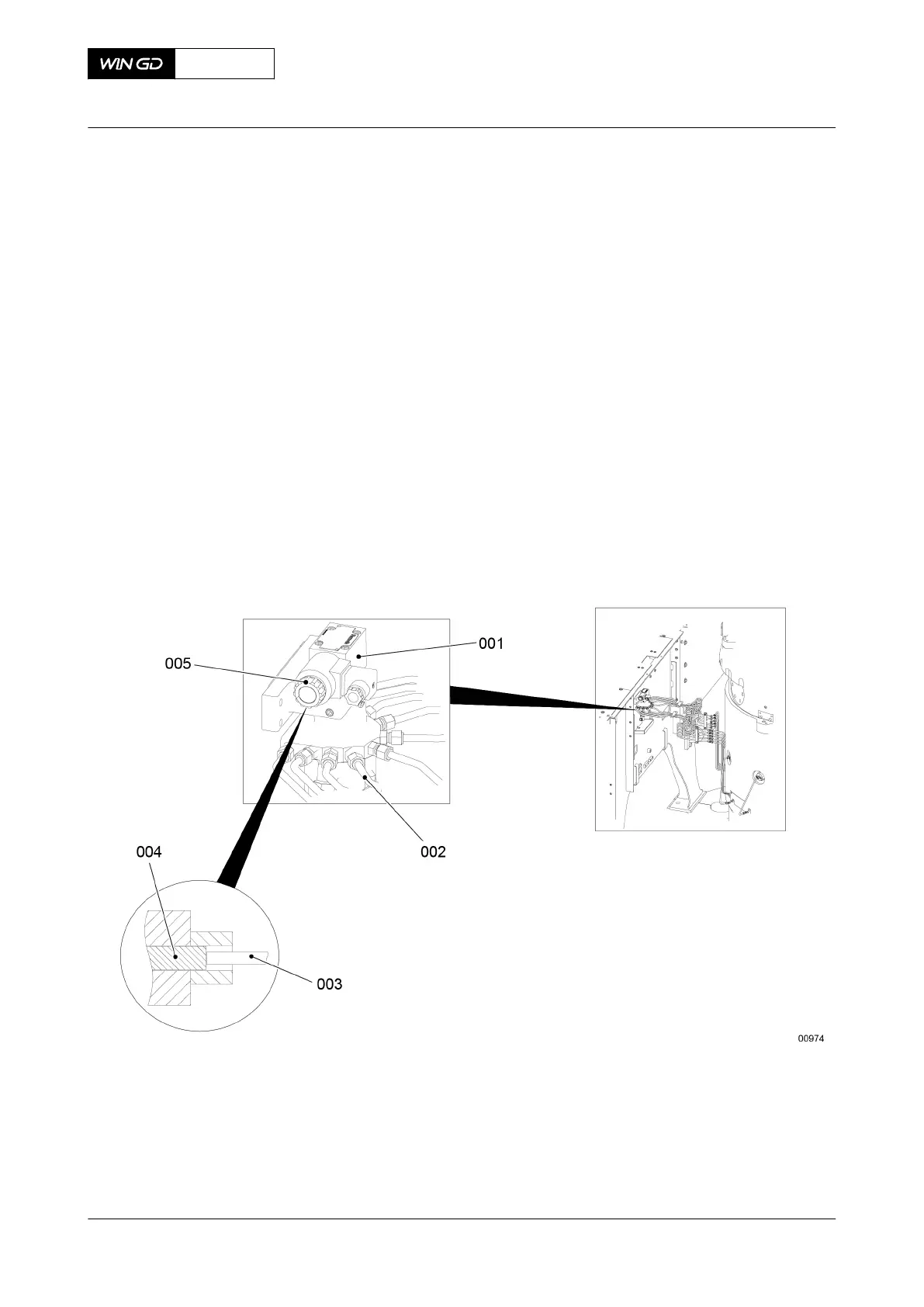

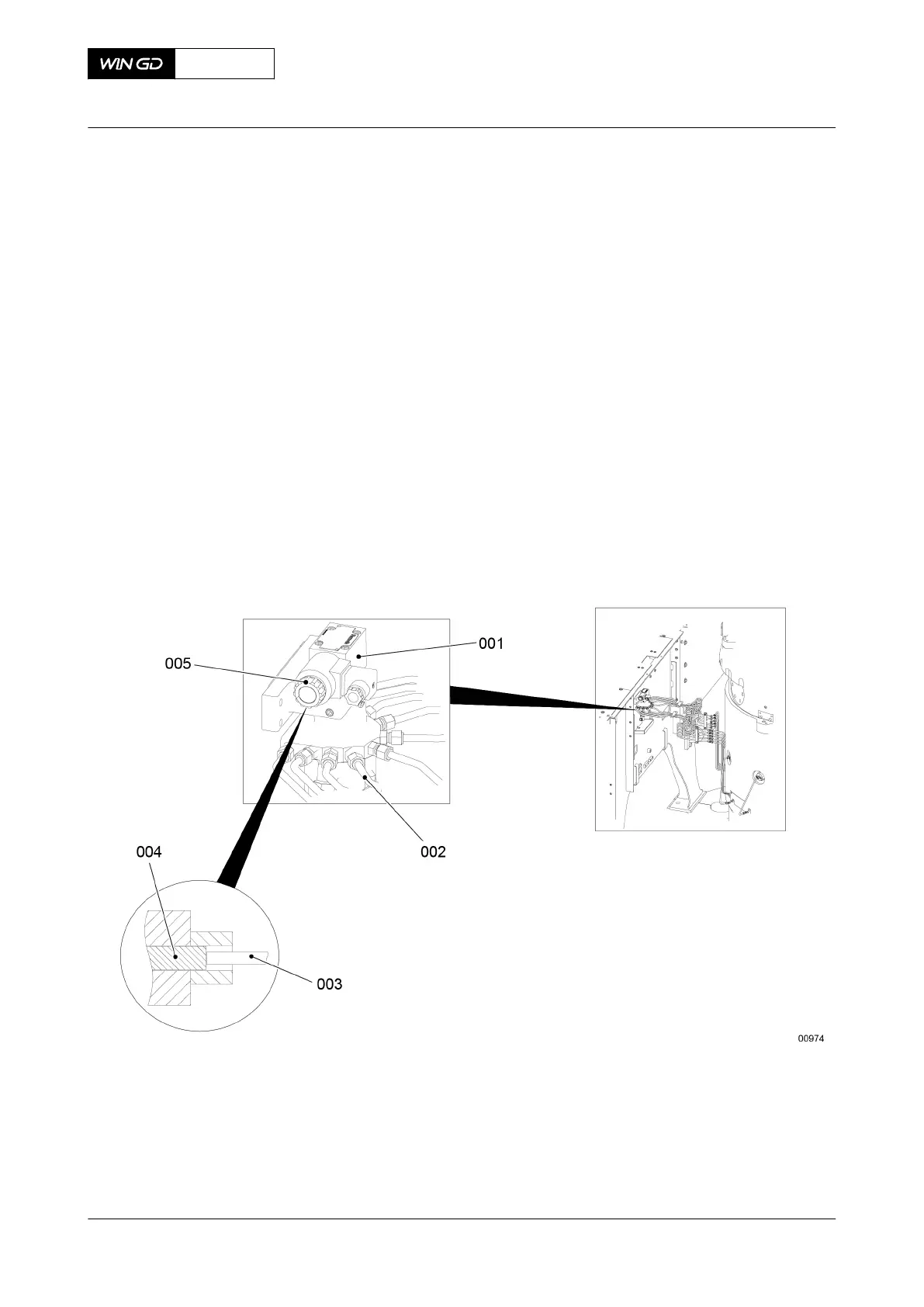

6 Manually release a lube pulse, for example use an applicable tool (003, Figure 12-1) to

push in the plunger (004) of the 4/2-way valve (005).

7 Look through the scavenge ports in the cylinder liner while the lubricating system

operates.

8 Make sure that the lubricating oil flows correctly on to the cylinder liner wall.

9 Make sure that the oil that flows has no air. If necessary, bleed the cylinder lubricating

pump (001) and the oil pipes (002), refer to section 12.1.2 Cylinder lubrication system -

bleed.

10 Set to OFF the cylinder lubricating system for the applicable cylinder.

11 Do Step 2 to Step 10 again for the other cylinders.

Fig 12-1 Cylinder lubrication system (example) - do a functional test

CLOSE UP

• None

X62DF

AA00-7218-00AAA-340A-A

Maintenance Manual Cylinder lubrication system - do a functional test

Winterthur Gas & Diesel Ltd.

- 671 - Issue 002 2020-10

Loading...

Loading...