General Troubleshooting 4-25

6 Time to lift plate up

(sec).

Reports the time between the

activation of the Tray 2 lift motor

and the detection of the raised lift

plate. Out of range values may

indicate a problem with the lifting

mechanism (which could effect

the following friction

measurement), or media left in

the tray.

7 Plate lifted average

fe.

Reports the peak effort required

to drive the pick shaft when the

nudger roller is in contact with

the separator pad.

A smaller value could indicate a

slipping clutch, missing nudger

assembly pressure spring, or

glazed/dirty roller/pad.

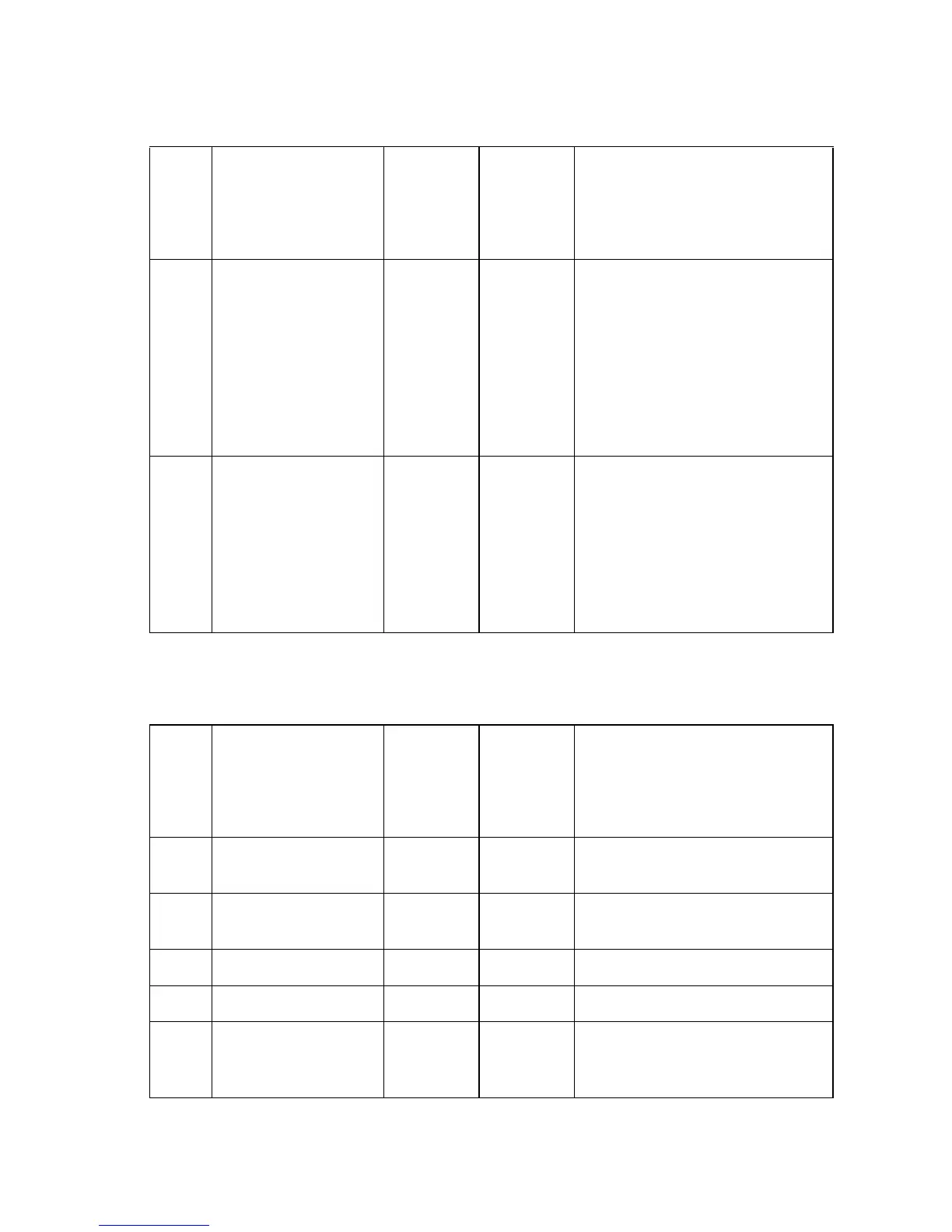

Paper Drive Power

Test picks paper from selected tray (test currently supports picking from Tray 2 only) and moves it

through either the simplex or duplex paper path to determine paper path power requirements.

R# Definition

Typical

Value

(8400)

Typical

Value

(8500/

8550) Actions

0 Tray Reports the tray from which the

test paper was picked.

1 Paper Size Reports the size of the picked

paper.

2Unused

3Unused

4 Tray 2 Pick Average

Power (watts)

Reports average of the power

over the pick interval (begin pick

to Deskew sensor).

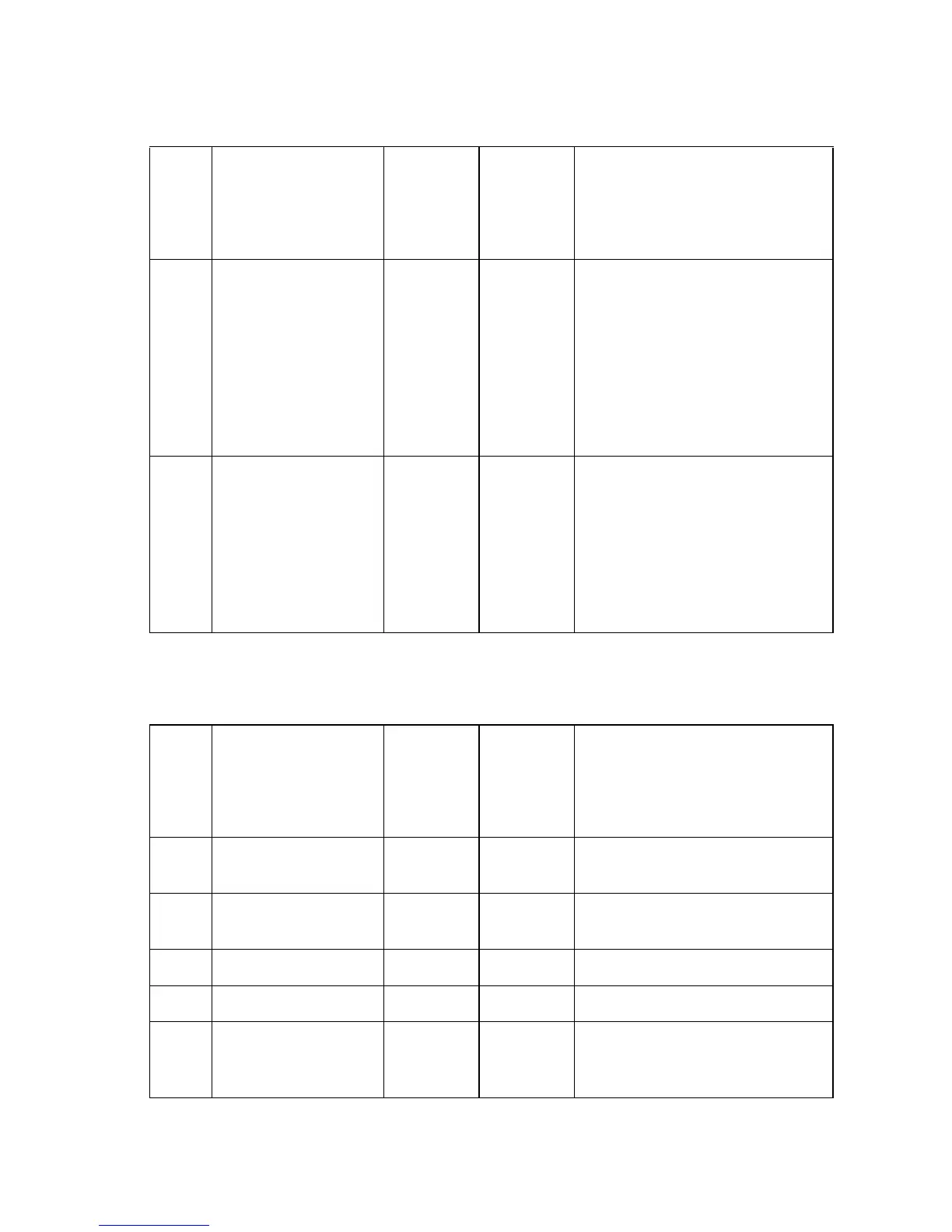

Tray 2, Tray 3, and Tray 4 Pick Shaft (Continued)

Test is the same for each pick shaft although for tray 2 the media path motor is used and for the

525-sheet feeders the corresponding pick/transport motor is used. Test determines if the shaft

can be driven by the clutch, if the nudger rollers are being driven, and the pick pad/nudger roller

friction.

R# Definition

Typical

Value

(8400)

Typical

Value

(8500/

8550) Actions

Loading...

Loading...