8.7 Autotuning with a Host Reference

8.7.4 Operating Procedure

8-37

6.

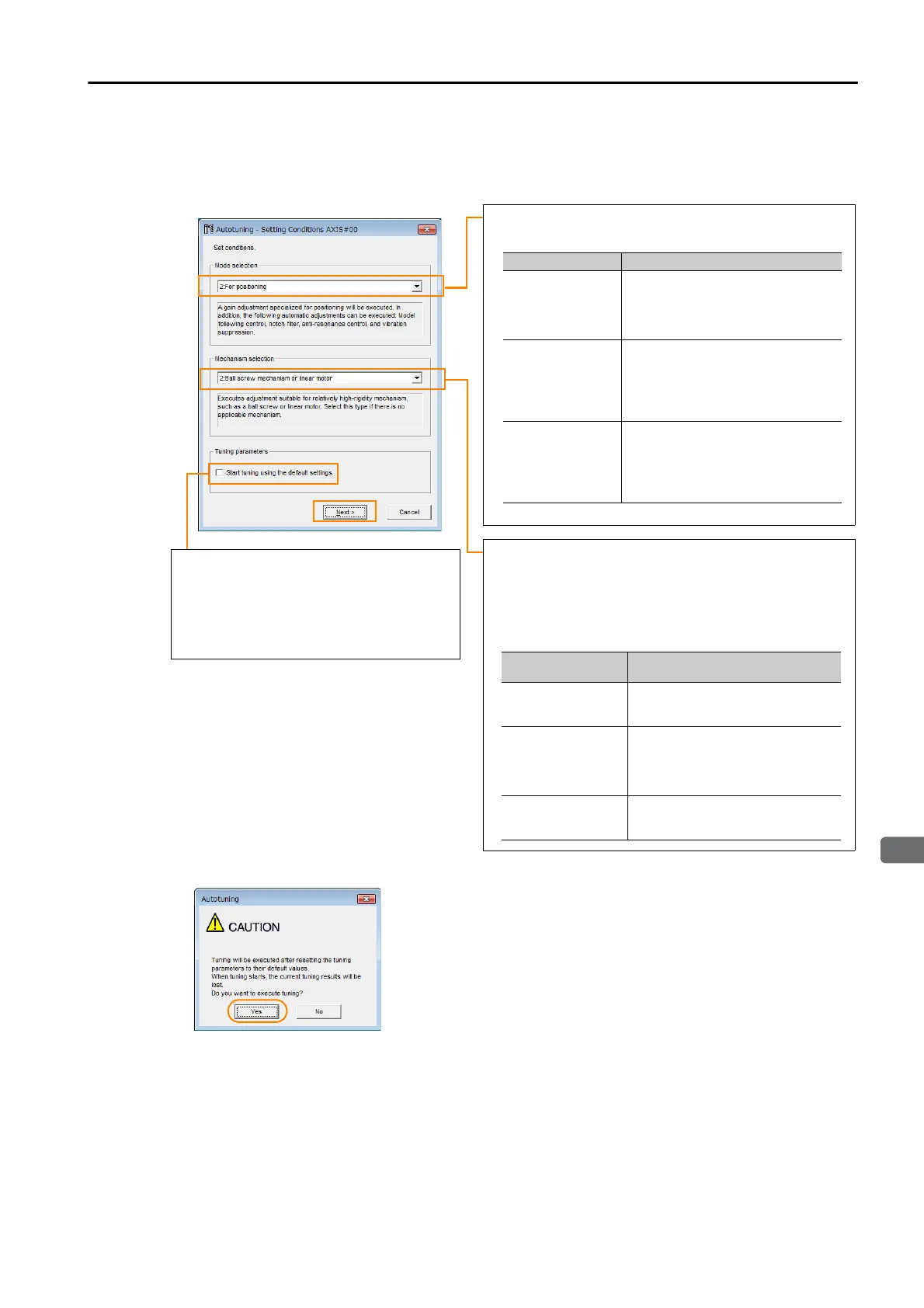

Set the conditions in the Mode selection Box and the Mechanism selection Box, and

then click the Next Button.

If you select the Start tuning using the default settings Check Box in the Tuning parameters Area,

the tuning parameters will be returned to the default settings before tuning is started.

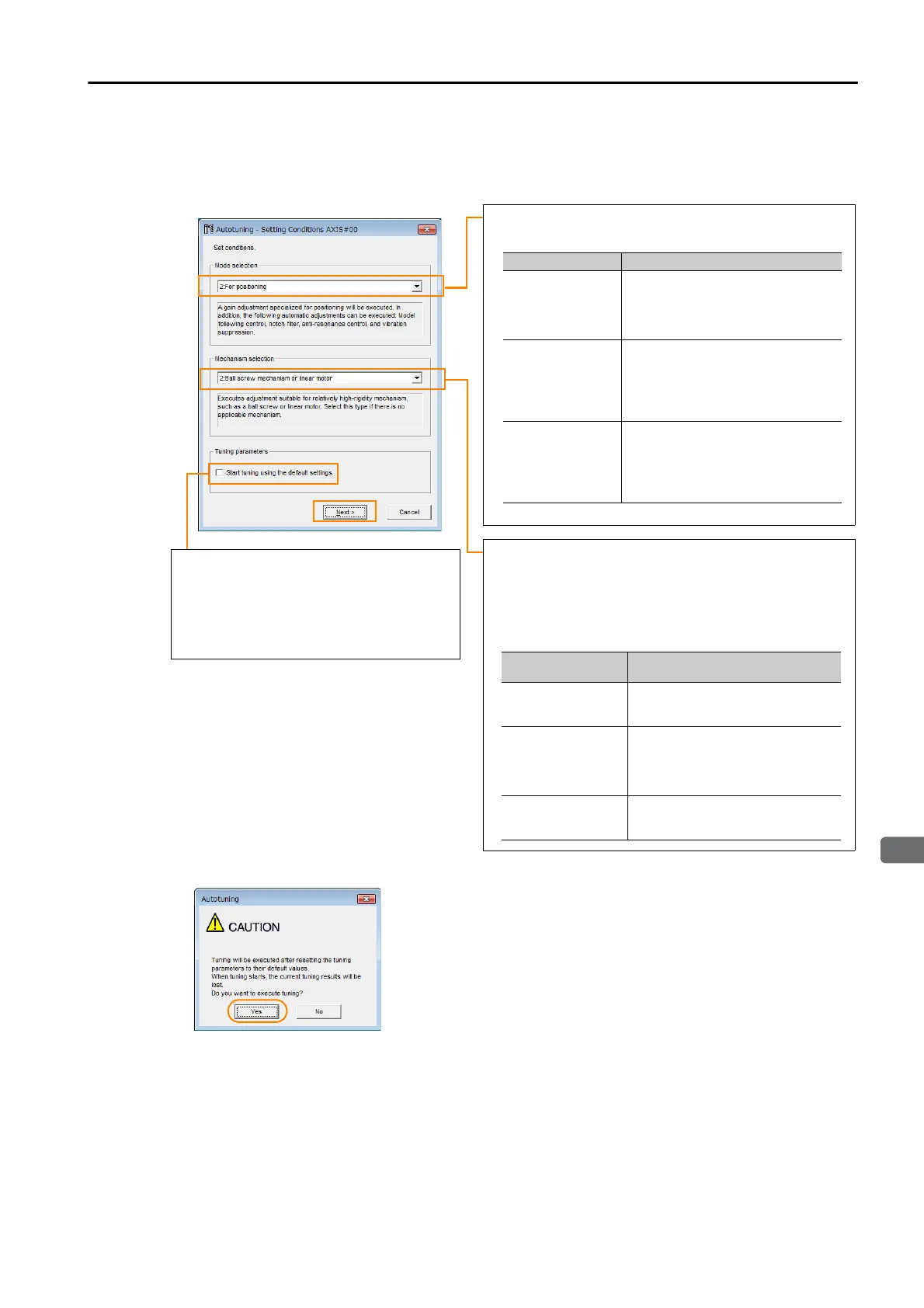

7.

Click the Yes Button.

• Mode selection Box

Set the mode.

• Mechanism selection Box

Select the type according to the machine element to

drive.

If there is noise or if the gain does not increase, better

results may be obtained by changing the rigidity type.

Select the type according to the following guidelines.

Mode Selection Description

1: Standard

Standard gain adjustment is per-

formed. In addition to gain adjust-

ment, notch filters and anti-

resonance control are automatically

adjusted.

2: For positioning

Tuning is performed for positioning

applications. In addition to gain

adjustment, model following control,

notch filters, anti-resonance control,

and vibration suppression are auto-

matically adjusted.

3: For positioning

especially to pre-

vent overshooting

Tuning is performed for positioning

applications with emphasis on elimi-

nating overshooting. In addition to

gain adjustment, notch filters, anti-

resonance control, and vibration sup-

pression are automatically adjusted.

• Tuning parameters Box

Specify the parameters to use for tuning.

If you select the Start tuning using the

default settings Check Box, the tuning

parameters will be returned to the default

settings before tuning is started.

Mechanism

Selection

Description

1: Belt mechanism

Tuning is performed for a mecha-

nism with relatively low rigidity, e.g.,

a belt.

2: Ball screw

mechanism or linear

motor

Tuning is performed for a mecha-

nism with relatively high rigidity, e.g.,

a ball screw or Linear Servomotor.

Use this setting if there is no other

appropriate setting.

3: Rigid model

Tuning is performed for a mecha-

nism with high rigidity, e.g., a rigid

body system.

Loading...

Loading...