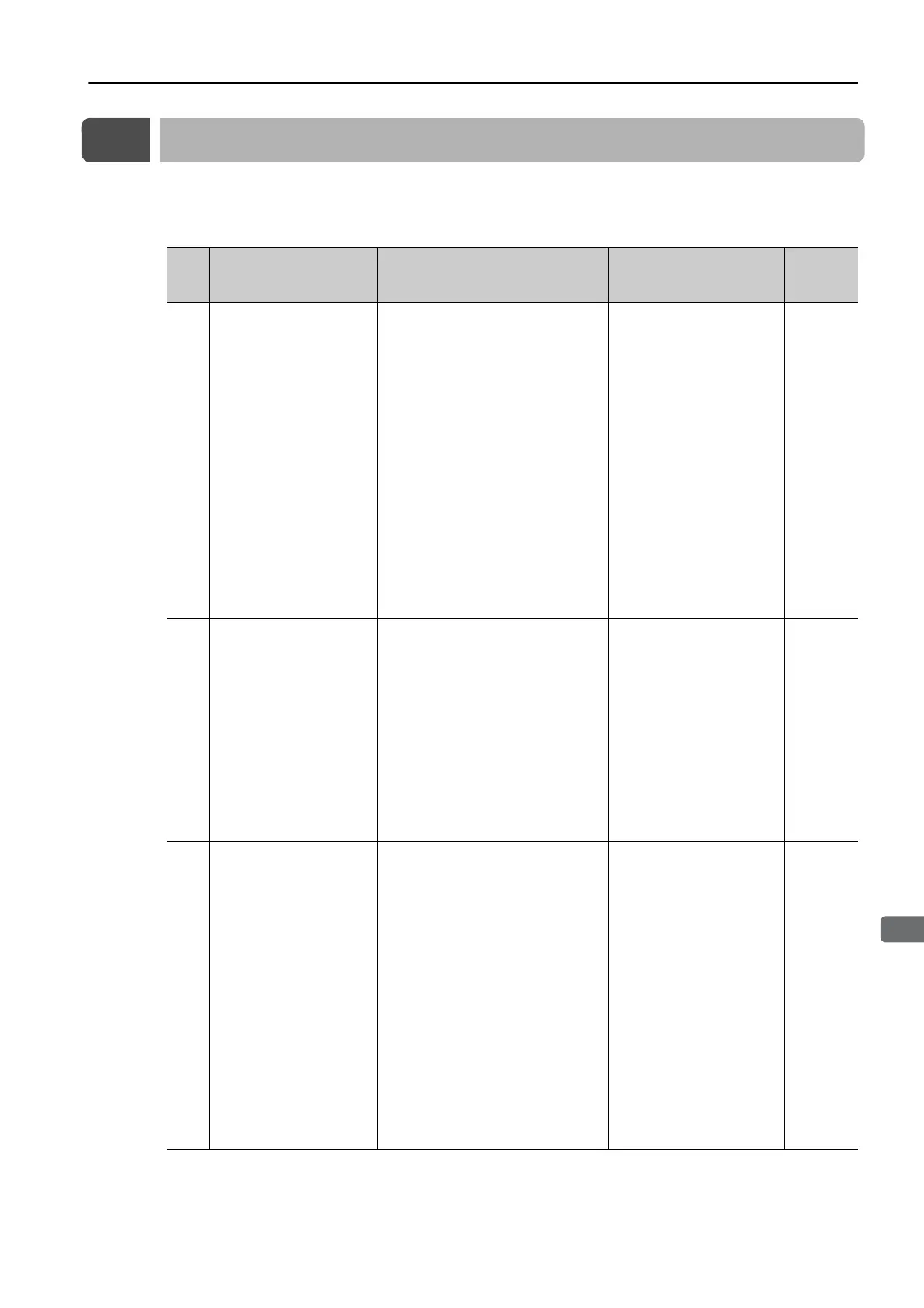

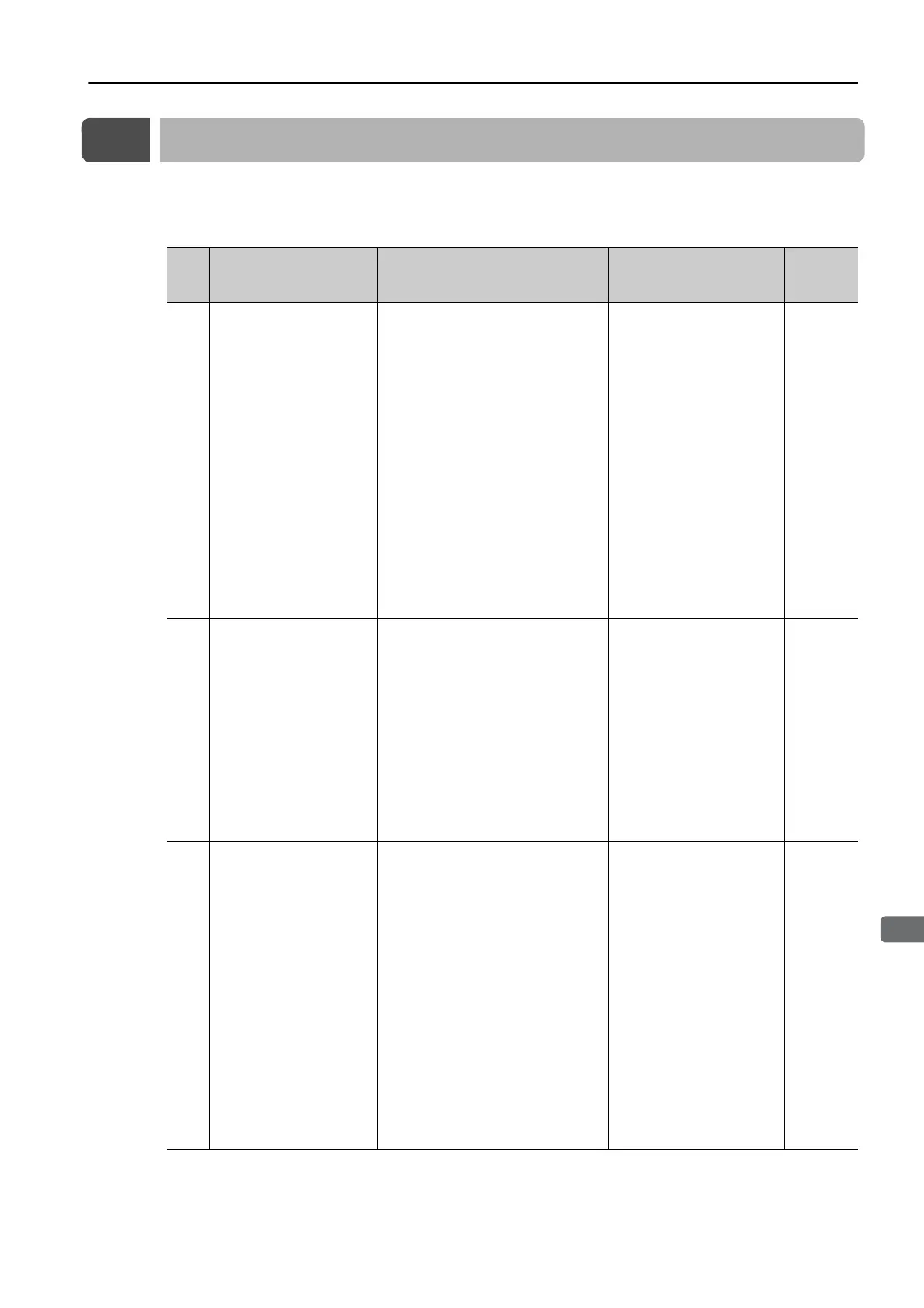

10.2 SERVOPACK Commissioning Procedure

10-3

10

Fully-Closed Loop Control

10.2

SERVOPACK Commissioning Procedure

First, confirm that the SERVOPACK operates correctly with semi-closed loop control, and then

confirm that it operates correctly with fully-closed loop control.

The commissioning procedure for the SERVOPACK for fully-closed loop control is given below.

Step Description Operation

Required Parameter

Settings

Con-

trolling

Device

1

Check operation of the

entire sequence with

semi-closed loop control

and without a load.

Items to Check

• Power supply circuit

wiring

• Servomotor wiring

• Encoder wiring

• Wiring of I/O signal

lines from the host con-

troller

• Servomotor rotation

direction, motor speed,

and multiturn data

• Operation of safety

mechanisms, such as

the brakes and the

overtravel mechanisms

Set the parameters so that the

SERVOPACK operates correctly in

semi-closed loop control without a

load and check the following

points. Set Pn002 to n.0 to

specify semi-closed loop control.

• Are there any errors in the SER-

VOPACK?

• Does jog operation function cor-

rectly when you operate the

SERVOPACK without a load?

• Do the I/O signals turn ON and

OFF correctly?

• Is power supplied to the Servo-

motor after the /S-ON signal is

sent?

• Does the Servomotor operate

correctly when a position refer-

ence is input by the host control-

ler?

• Pn000 (Basic Function

Select Switch 0)

• Pn001 (Basic Function

Select Switch 1)

• Pn002 = n.X

(External Encoder

Usage)

• Pn20E (Electronic Gear

Ratio (Numerator))

• Pn210 (Electronic Gear

Ratio (Denominator))

• PnB03 to PnB12)

(Input Signal Selections)

• PnB15 to PnB1E)

(Output Signal Selec-

tions)

SERVO-

PACK or

host con-

troller

2

Check operation with the

Servomotor connected

to the machine with

semi-closed loop control.

Items to Check

• Initial response of the

system connected to

the machine

• Movement direction,

travel distance, and

movement speed as

specified by the refer-

ences from the host

controller

Connect the Servomotor to the

machine. Set the moment of inertia

ratio in Pn103 using autotuning

without a host reference.

Check that the machine’s move-

ment direction, travel distance, and

movement speed agree with the

references from the host controller.

Pn103 (Moment of Inertia

Ratio)

Host con-

troller

3

Check the external

encoder

.

Items to Ch

eck

Is the signal from the

external encoder

received correctly?

Set the parameters related to fully-

closed loop control and move the

machine with your hand without

turning ON the power supply to the

Servomotor. Check the following

status with the Digital Operator or

SigmaWin+.

• Does the fully-closed feedback

pulse counter count up when the

Servomotor moves in the forward

direction?

• Is the travel distance of the

machine visually about the same

as the amount counted by the

fully-closed feedback pulse

counter?

Note: The unit for the fully-closed feed-

back pulse counter is pulses,

which is equivalent to the exter-

nal encoder sine wave pitch.

• Pn002 = n.X

(External Encoder

Usage)

• Pn20A (Number of

External Scale Pitches)

• Pn20E (Electronic Gear

Ratio (Numerator))

• Pn210 (Electronic Gear

Ratio (Denominator))

• Pn281 (Encoder Output

Resolution)

• Pn51B (Motor-Load

Position Deviation Over-

flow Detection Level)

• Pn522 (Positioning

Completed Width)

• Pn52A (Multiplier per

Fully-closed Rotation)

–

Continued on next page.

Loading...

Loading...