Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 193

Appendix A

Interconnect Diagrams

This appendix provides wiring examples and system block diagrams for your

Kinetix® 5500 system components.

Interconnect Diagram Notes

This appendix provides wiring examples to assist you in wiring the

Kinetix 5500 drive system. These notes apply to the wiring examples on the

pages that follow.

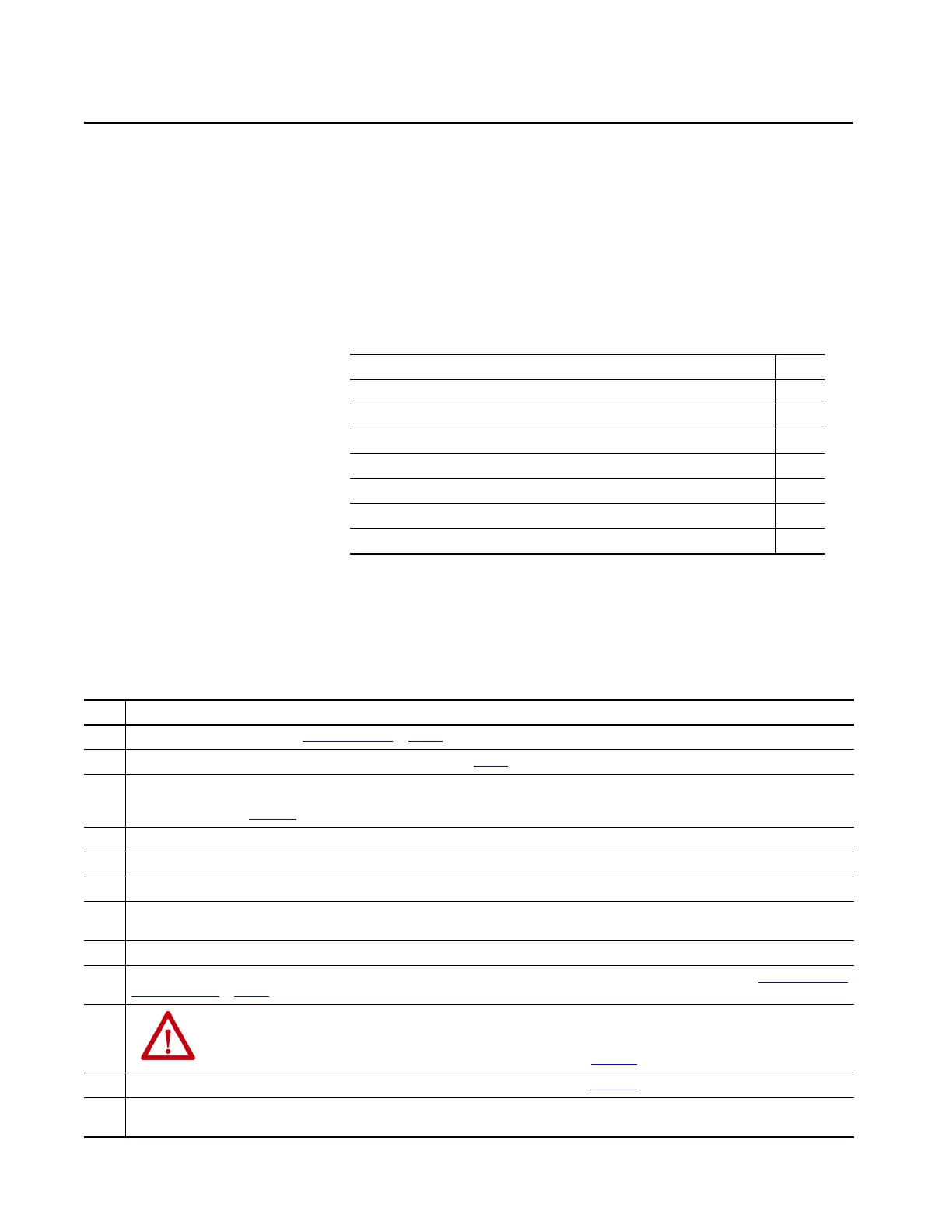

Topic Page

Interconnect Diagram Notes 193

Power Wiring Examples 194

Bus-sharing Wiring Examples 196

Shunt Resistor Wiring Example 198

Kinetix 5500 Servo Drive and Rotary Motor Wiring Examples 199

Kinetix 5500 Drive and Linear Actuator Wiring Examples 201

System Block Diagrams 205

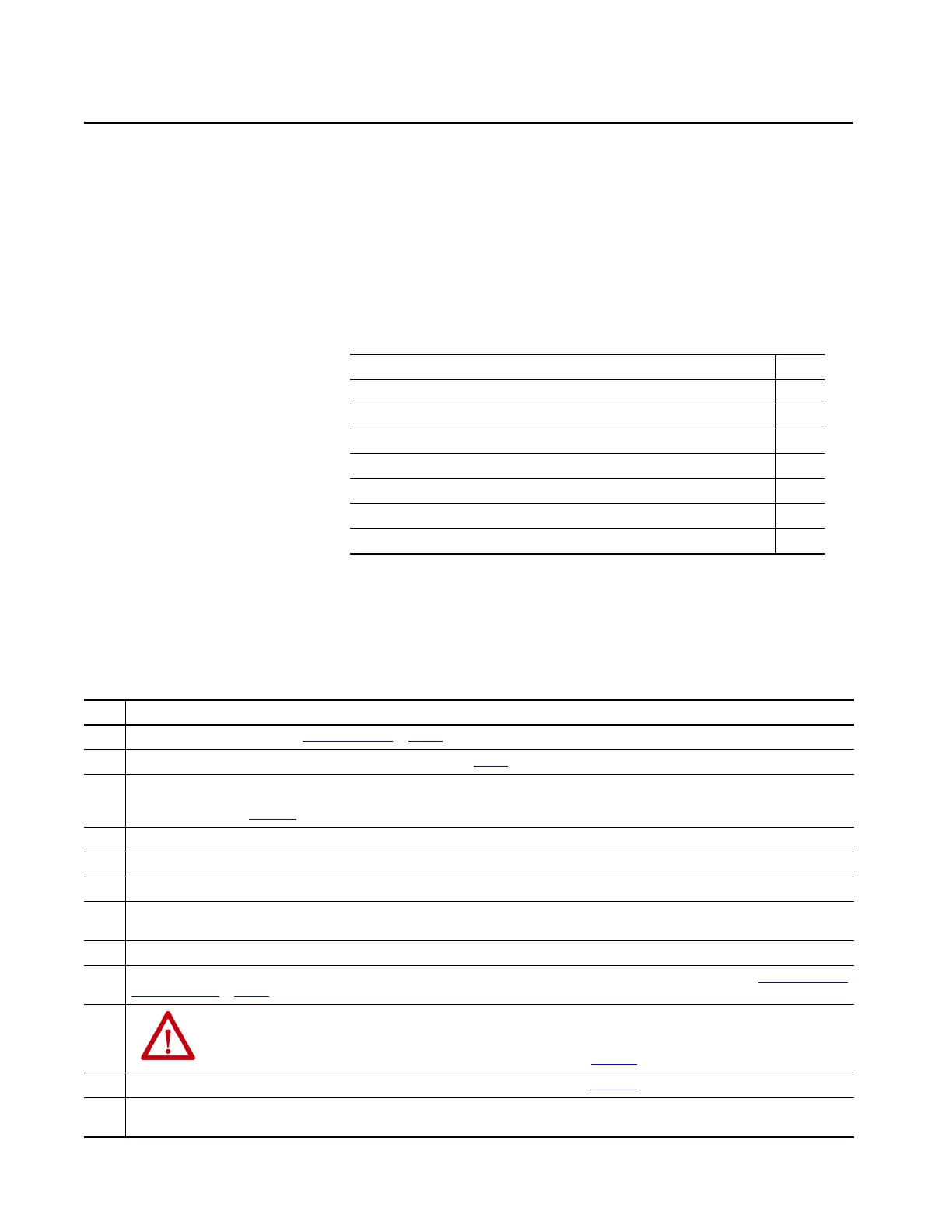

Table 75 - Interconnect Diagram Notes

Note Information

1 For power wiring specifications, refer to Wiring Requirements

on page 82.

2 For input fuse and circuit breaker sizes, refer to Circuit Breaker/Fuse Selection on page 34

.

3 AC (EMC) line filter is required for EMC compliance. Place line filter as close to the drive as possible and do not route very dirty wires in wireway. If routing in wireway is

unavoidable, use shielded cable with shields grounded to the drive chassis and filter case. For AC line filter specifications, refer to Kinetix Servo Drives Specifications

Technical Data, publication KNX-TD003

.

4 Terminal block is required to make connections.

5 Cable shield clamp must be used to meet CE requirements.

6 PE ground connection bonded to the panel must be used to meet CE requirements.

7 DC connector covered with protective knockout is default configuration. Remove knockout to insert DC bus T-connector and bus-bars. Do not attach discrete wiring to the

DC bus terminals is.

8 Internal shunt wired to the RC connector is default configuration. Remove internal shunt wires to attach external shunt wires.

9 Default configuration for ground screws is for grounded power at user site. For ungrounded or corner-grounded power, remove the screws. Refer to Determine the Input

Power Configuration on page 75 for more information.

10

ATTENTION: Implementation of safety circuits and risk assessment is the responsibility of the machine builder. Please

reference international standards ISO 14121-1 and ISO 13849-1 estimation and safety performance categories. For more

information refer to Understanding the Machinery Directive, publication SHB-900

.

11 For motor cable specifications, refer to Kinetix Motion Accessories Specifications Technical Data, publication KNX-TD004.

12 MPL-A15xx…MPL-A45xx, MPM-A115xx…MPM-A130xx, MPF-A3xx…MPF-A45xx, MPS-Axxx, MPAR-Axxx, MPAS-Axxx, and LDAT-Sxx-xBx encoders use the +5V DC

supply.

Loading...

Loading...